A professional equipment for efficiently and uniformly mixing powder and granular materials

![]()

![]()

Price:$3,800.00-$25,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-15min

Capacity: 100L-30000L

Range of Spindle Speed(r.p.m): 44 - 175 r.p.m

Voltage: 220V/380V/customize

Power: 13.5-75kw

Weight: 300 kg-1000kg

Application: Manufacturing Plant, Food & Beverage Factory, Construction works , Energy & Mining

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Conical twin screw mixer is a common mixing equipment used to uniformly mix different powders, granules or pigments. It consists of a conical container and two intertwined screws. The rotation of the screws pushes the material upward from the bottom of the container, and then pulls it back down from the top of the container, forming strong stirring and shearing effects, thereby achieving rapid mixing of the material.

The conical twin screw mixer has many advantages. First, it can achieve efficient mixing, mixing materials with different ingredients quickly and evenly to ensure product quality and consistency. Secondly, due to the intertwined motion of the twin screws, the shear force and extrusion force during the mixing process help to break the clumps and improve the dispersion of the material. In addition, the tapered design allows the mixer to have a larger volume and smaller footprint, making it suitable for production lines of different sizes. Conical twin screw mixer is widely used in chemical, pharmaceutical, food and other industries to meet the requirements of efficient and uniform material mixing.

Conical twin screw mixers are widely used in many industries. Its application industries and mixed materials will be introduced in detail below.

Chemical industry: In the chemical industry, conical twin screw mixers are often used for mixing powder and granular materials. It can be used to mix various chemical raw materials, such as pigments, dyes, plastic powder, rubber powder, chemical fertilizers, etc. These materials usually have different densities, particle sizes and properties. Through the stirring action of the mixer, they can be mixed evenly to meet the requirements of chemical production.

Pharmaceutical industry: In the pharmaceutical industry, conical twin screw mixers are widely used in the mixing process of pharmaceutical processes. It can be used to mix pharmaceutical raw materials, such as pharmaceutical powders, tablet granules, herbal powders, etc. Through the stirring action of the mixer, medicinal materials with different ingredients can be evenly mixed to ensure the uniformity and stability of the medicine.

Food industry: In the food industry, conical twin screw mixers are often used for mixing food additives, condiments, dry mixes, etc. It can evenly mix different food raw materials, such as flour, sugar powder, protein powder, spices, etc. The mixing function of the mixer can fully mix these raw materials to ensure the taste and quality of the food.

Pesticide industry: In the pesticide industry, conical twin screw mixers are often used for the preparation of pesticide powders. It can mix different types of pesticide powders to meet the requirements of the formula. The stirring action of the mixer can evenly mix the pesticide powder to ensure the uniformity and stability of the pesticide.

Other industries: The conical twin screw mixer can also be used in other industries, such as the building materials industry, metallurgical industry, environmental protection industry, etc. In the building materials industry, it can be used to mix cement, gypsum and other materials; in the metallurgical industry, it can be used to mix ore powder; in the environmental protection industry, it can be used to mix waste, etc.

The working principle of conical twin screw mixer can be briefly described as follows:

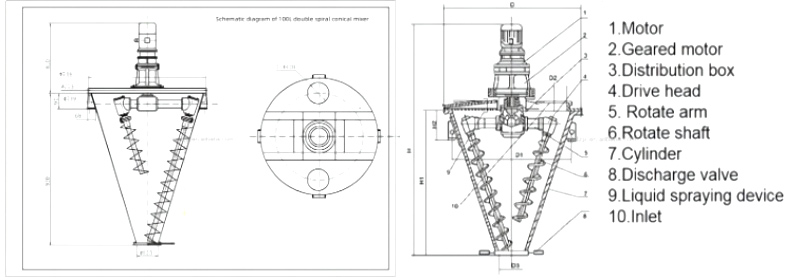

Structure: The conical twin screw mixer consists of two mutually spiral screws, which are located in a conical container. The screws usually have the same diameter but may have different pitches.

Movement mode: The screw is driven by a motor and rotates in the container. One screw is called the main screw and the other screw is called the secondary screw. The rotation direction of the main screw is opposite to that of the auxiliary screw, and their rotation speeds can be the same or different.

Material flow: When the screw rotates, the material is pushed and squeezed, and moves along the axis of the screw. Due to the spiral shape of the screw, the material forms a continuous flow path within the container.

Mixing effect: The material is continuously lifted, pushed, squeezed and sheared under the action of the screw. This shearing and squeezing action allows materials with different components to fully contact and mix, achieving a uniform mixing effect.

Temperature control: Conical twin-screw mixers usually have heating or cooling functions, and the container can be controlled by external heating or cooling media to meet specific process requirements.

Efficient mixing

The conical twin screw mixer provides powerful shearing and squeezing forces through the rotation and interweaving motion of the screw, allowing the material to be mixed quickly and evenly. Compared with traditional mixing equipment, it has higher mixing efficiency.

Good uniformity

Due to the special structure and movement mode of the screw, the conical twin screw mixer can fully contact and mix materials with different components to achieve a highly uniform mixing effect. This helps ensure product quality and consistency.

Strong adaptability

conical twin screw mixer is suitable for a variety of different materials, including powders, granules, solids, liquids, etc. It can handle materials of different particle sizes, different proportions and different properties, and has strong adaptability.

Versatility

The conical twin screw mixer can not only achieve mixing, but also perform dispersion shearing, dissolution reaction and other processes. It can meet different process needs and provide multiple functions, making it more flexible and versatile in the production process.

Easy to operate

conical twin screw mixer usually has a simple operating interface and control system, which is easy to operate and control. The operator can achieve precise control of the mixing process by adjusting the screw speed, temperature and other parameters.

High reliability

The conical twin screw mixer has a reasonable structural design and is made of wear-resistant and corrosion-resistant materials, which has high reliability and durability. It can maintain stable performance under long-term, high-load working conditions and reduce equipment maintenance and failure rates.

| Model | Full Volume(L) | Effective loading Volume(L) | rotate speed((r.p.m) | Weight(kg) | Power(kw) |

| DZDS-300 | 300 | 120-180 | 2/68 | 400 | 3 |

| DZDS-500 | 500 | 200-300 | 2/68 | 550 | 3 |

| DZDS-1000 | 1000 | 400-600 | 2/57 | 1200 | 4 |

| DZDS-2000 | 2000 | 800-1200 | 2/57 | 1500 | 5.5 |

| DZDS-3000 | 3000 | 1200-1800 | 2/57 | 2300 | 7.5 |

| DZDS-4000 | 4000 | 1600-2400 | 2/57 | 2800 | 11 |

| DZDS-6000 | 6000 | 2400-3600 | 2/57 | 3600 | 15 |

| DZDS-6000 | 6000 | 2400-3600 | 2/57 | 3600 | 15 |

| DZDS-10000 | 10000 | 4000-6000 | 2/57 | 4200 | 18.5 |

| DZDS-15000 | 15000 | 6000-9000 | 2/57 | 4900 | 22 |

| DZDS-20000 | 20000 | 8000-12000 | 2/57 | 5800 | 37 |

A. Mixing effect

Conical twin screw mixer has two mixing screws, one long and one short. In practical applications, single (one long screw) and three (two short and one long symmetrically arranged) screws can also be used according to the equipment specifications.

B. Cooling and heating

Various types of jackets can be added outside the mixer barrel to cool or heat the material by injecting hot and cold media into the jacket; Cooling is generally pumped into industrial water, and heating can be carried out by introducing steam or heat transfer oil.

C. Mixing with liquid

Insert a spray pipe at the intermediate shaft position of the mixer and connect it to the atomizing nozzle to achieve liquid mixing; By selecting specific materials, acid and alkaline liquid materials can be added for powder liquid mixing.

D. Customized pressure resistant cylinder cover

The pressure resistant cylinder cover can be made into a head type, and the cylinder body can be thickened to withstand positive or negative pressure, while reducing residue for easy cleaning.

E. Feeding method

It can be manually fed, fed by vacuum feeding machines, and fed by conveying machinery. In specific processes, the mixer cylinder can be made into a negative pressure chamber, and a hose can be used to suck dry materials with good fluidity into the mixing chamber for mixing.

F. Discharge method

Standard equipment generally adopts a plum blossom shaped "dislocation valve", which is tightly attached to the bottom of the long spiral, effectively reducing mixing dead angles. The driving form is available in manual and pneumatic options.

A chemical company needs to efficiently and uniformly mix powder materials during the production process to ensure product quality and consistency. To meet this need, they chose an advanced conical twin screw mixer as the solution. The mixer has the characteristics of efficient mixing and good uniformity, and can fully contact and mix powder materials with different components to ensure the consistency of the mixing effect. In addition, the mixer is versatile and can adapt to different process needs, providing flexible operation and control. By using the conical twin screw mixer, the chemical company successfully improved production efficiency, reduced product quality fluctuations, and received unanimous praise from customers. This case fully demonstrates the application advantages and value of conical twin screw mixer in the chemical industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.