A device that uniformly mixes different materials by rotating a screw, with high mixing effect, high efficiency, perfect mixing and short mixing time.

![]()

![]()

Price:$1,500.00-$6,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-10min

One-time mixing: 100-5000 (kg)

Capacity: 200L-50,000L

Voltage: 220V/380V/customize

Material: Carbon Steel, 304L Stainless Steel and 316L Stainless Steel

Power: 3-37kw

Application: Various processing activities in the pharmaceutical, food, plastics, metals and minerals, nuclear energy, chemicals, pigments and coatings industries

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Screw mixer, also known as a screw conveyor mixer, is a type of mixing equipment commonly used in various industries for blending and homogenizing powders, granules, and other materials. The primary component of a screw mixer is a rotating screw or auger that moves material along its length while simultaneously mixing it.

There are several different screw configurations available for screw mixers, each designed to meet specific mixing requirements and optimize the blending process. They can handle a wide range of materials, including powders, granules, liquids, and pastes, making them versatile for various applications.

Here are the primary functions of screw mixers:

Blending: Combining various ingredients into a homogeneous mixture.

Mixing: Ensuring uniform distribution of components within a mixture.

Kneading: Compressing and working materials, especially doughs and pastes.

Dispersing: Breaking up clumps or agglomerations in materials.

Aerating: Incorporating air into materials for applications like baking or creating foams.

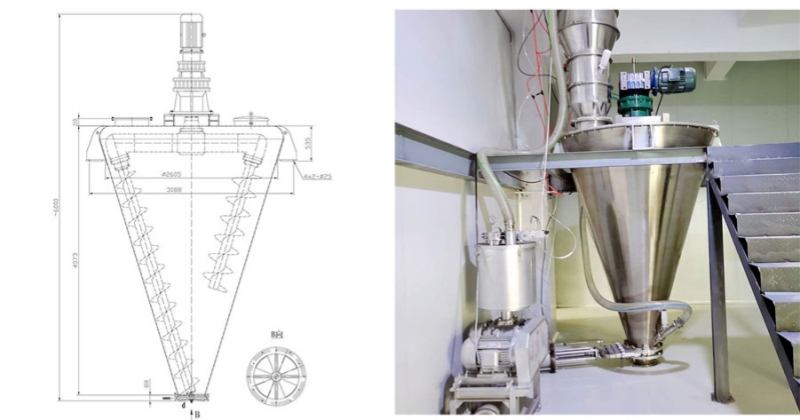

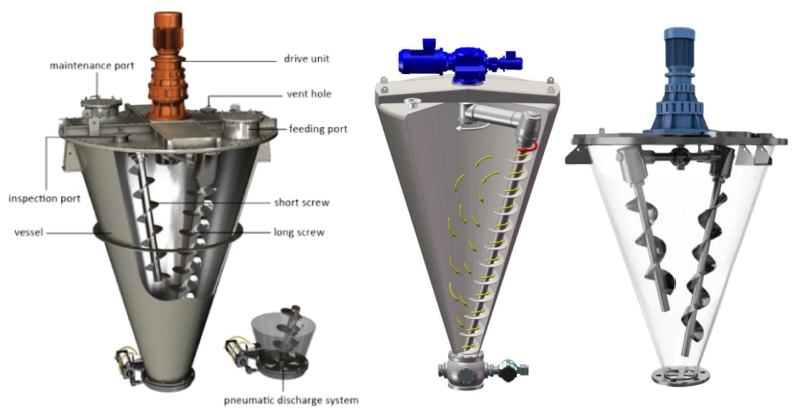

Conical Screw Mixer

Has a conical-shaped container, which helps to prevent materials from settling and ensures thorough mixing.The conical design promotes better flow and mixing efficiency compared to traditional cylindrical mixers.Helps prevent segregation of materials, especially when dealing with different particle sizes.

Barrel Volume:100-30000L

Max. Loading Volume:20000 L

Application:Capable of handling a wide range of materials, including powders, granules, and pastes.

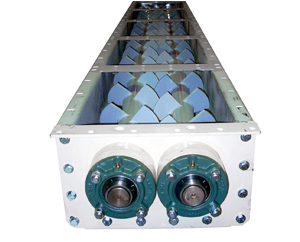

Horizontal Screw Mixer

He most common type, it has a horizontal cylindrical container and is suitable for a wide range of applications. Horizontal screw mixers provide better mixing uniformity and are more suitable for continuous mixing applications compared to paddle mixers.

Each mixing amount: 100-6000kg

Mixing time: 8-20min

Application: Can handle a wide range of materials, including powders, granules, pastes, and liquids, making them versatile across various industries.

Double Screw Mixer

Features two parallel screws rotating in opposite directions, providing intense mixing for materials with varying densities or viscosities.Due to the twin-screw design, the mixing effect is more uniform, which can ensure that various materials are fully mixed.

Each processing capacity range: 1000-3000L

Production capacity: 10-200t/h

Application: Suitable for mixing viscous materials, while fluid bed mixers are more suitable for particles that flow easily.

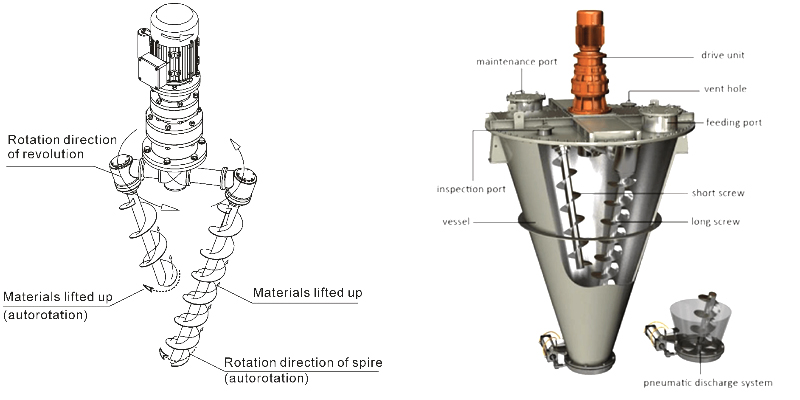

The working principle of the screw mixer is based on the movement of the rotating screw, and the materials are mixed through the pushing and stirring action of the screw. The following is the general working principle of a screw mixer:

Feeding: Materials are input into the working chamber of the screw mixer through the feeding port. The feed inlet is usually located at one end of the screw mixer.

Stirring and pushing: There are one or more spiral screws inside the screw mixer, and the screw is driven to rotate by a motor or other power source. When the screw rotates, the material is pushed by the screw and moves along the spiral axis of the screw. At the same time, the shape and pitch of the screw will also produce a stirring effect to mix the materials.

Mixing and homogenization:During the working process of the screw mixer, the materials are continuously pushed and stirred to achieve mixing and homogenization. Different components of the material gradually reach a state of uniform mixing after multiple cycles and contacts.

Discharge: After mixing is completed, the material is discharged from the screw mixer through the discharge port. The discharge port is usually located at the other end of the screw mixer.

The working principle of the screw mixer is based on the rotational movement and pushing and stirring action of the screw. Through continuous stirring and pushing, the materials are mixed and homogenized. The design and parameters of the screw mixer (such as screw shape, pitch, speed, etc.) will have an impact on the mixing effect. Therefore, in practical applications, selection and adjustment need to be made based on the characteristics of the material and mixing requirements.

Uniform mixing

The screw mixer can uniformly mix the materials through the rotation and stirring of the screw. The shape and pitch of the screw are designed reasonably so that the materials are fully mixed and dispersed during the mixing process, thereby improving the mixing effect.

High efficiency

The screw mixer has a high mixing efficiency and processing capacity. Since the materials are continuously pushed and stirred inside the screw mixer, the mixing time is relatively short, which can quickly complete the mixing process and improve production efficiency.

Strong adaptability

The screw mixer is suitable for mixing a variety of materials. Whether they are powders, granules or liquids, as well as materials of different particle sizes and specific gravity, screw mixers can effectively mix them. At the same time, screw mixers are also suitable for application needs in different industrial fields.

Easy to operate

The operation of the screw mixer is relatively simple, just set the appropriate parameters and control the rotation speed. At the same time, the screw mixer is relatively convenient to maintain and clean, saving manpower and time costs.

Low energy consumption

The energy consumption of screw mixers is relatively low. Due to its efficient mixing capacity and optimized structural design, the screw mixer can reduce energy loss and consumption during the mixing process.

Suitable for special process requirements

The screw mixer can be customized and designed according to special process requirements. For example, the materials can be selected and adjusted based on their temperature, pressure, reactivity and other characteristics to meet the mixing needs of a specific process.

| Model | Full Volume(L) | Effective loading Volume(L) | rotate speed((r.p.m) | Weight(kg) | Power(kw) |

| DZDS-300 | 300 | 120-180 | 2/68 | 400 | 3 |

| DZDS-500 | 500 | 200-300 | 2/68 | 550 | 3 |

| DZDS-1000 | 1000 | 400-600 | 2/57 | 1200 | 4 |

| DZDS-2000 | 2000 | 800-1200 | 2/57 | 1500 | 5.5 |

| DZDS-3000 | 3000 | 1200-1800 | 2/57 | 2300 | 7.5 |

| DZDS-4000 | 4000 | 1600-2400 | 2/57 | 2800 | 11 |

| DZDS-6000 | 6000 | 2400-3600 | 2/57 | 3600 | 15 |

| DZDS-6000 | 6000 | 2400-3600 | 2/57 | 3600 | 15 |

| DZDS-10000 | 10000 | 4000-6000 | 2/57 | 4200 | 18.5 |

| DZDS-15000 | 15000 | 6000-9000 | 2/57 | 4900 | 22 |

| DZDS-20000 | 20000 | 8000-12000 | 2/57 | 5800 | 37 |

Screw: The primary component, it rotates within the cylindrical container and pushes the materials towards the discharge port. The screw's design can vary depending on the specific application and the desired mixing intensity.

Container: The cylindrical vessel that encloses the screw and the materials being mixed. It can be made from different materials such as stainless steel, mild steel, or other suitable materials depending on the nature of the materials being processed.

Drive Mechanism: The motor or other power source that drives the screw's rotation.

Discharge Port: The opening at the end of the container through which the mixed materials are expelled.

Screw mixers offer a variety of screw configurations, each designed to optimize mixing performance for specific applications. Here are some common types:

1. Continuous Flight Screw: Continuous flight screws have a continuous helical flight that runs the length of the screw.Provides gentle mixing and conveying of materials, suitable for fragile or heat-sensitive materials.

2. Ribbon Screw: Ribbon screws have multiple helical blades that are welded to a solid shaft.Offers improved mixing efficiency and more aggressive mixing action compared to continuous flight screws.

3.Paddle Screw: Paddle screws have paddles or agitators mounted on the shaft at regular intervals.Ideal for mixing cohesive materials and ensuring thorough blending of materials.

4.Double Flight Screw: Double flight screws consist of two helical flights wound around the shaft.Offers increased mixing capacity and efficiency, useful for applications requiring faster mixing.

5.Tapered Screw: Tapered screws have flights that gradually increase or decrease in diameter along the length of the screw.Facilitates controlled mixing and material flow, particularly useful for handling materials with varying densities.

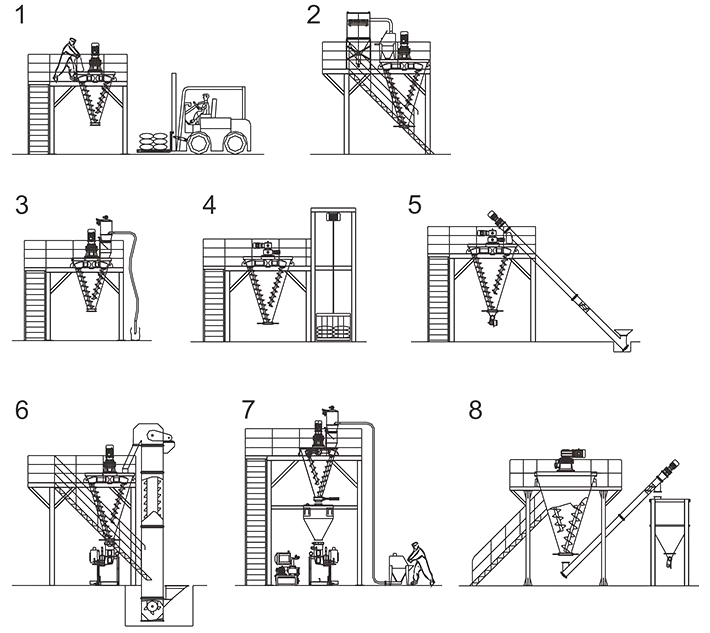

Configuration 1: conical mixer with manually feeding.

Configuration 2: conical mixer, manually feeding device with dust collector.

Configuration 3: conical mixer with vacuum feeder.

Configuration 4: conical mixer with crane.

Configuration 5: conical mixer with screw conveyor.

Configuration 6: conical mixer with bucket elevator.

Configuration 7: simple production line with conical mixer, vacuum feeder, storage tank and auto-packing machine.

Configuration 8: simple production line with conical mixer, manually feeding, screw conveyor to storage tank and auto-packing.

Screw mixers are widely used in various industries. Here are some common areas and applications:

Chemical industry: Screw mixers are used in the chemical industry to mix and homogenize various chemical materials, such as the mixing, reaction, and dissolution of powders, granules, and liquids. They are commonly used in the production of chemical products, dyes, pigments, plastics, rubber, adhesives, etc.

Food and Beverage Industry:Screw mixers are used in the food and beverage industry to mix and evenly distribute various ingredients and additives. They are often used to make flour, condiments, dry pastries, biscuits, feed, juice, beverages, etc.

Pharmaceutical industry: Screw mixers are used in the pharmaceutical industry to mix and evenly distribute pharmaceutical raw materials, excipients and additives. They are commonly used in the preparation of pharmaceutical preparations, powders, capsules, granules, ointments, etc.

Building materials industry: Screw mixers are used in the building materials industry to mix and evenly distribute cement, gypsum, mortar, paint, pigments and other materials. They are commonly used in the production of concrete, mortar, coatings, gypsum boards, etc.

Environmental protection industry: Screw mixers are used in the environmental protection industry to mix and treat wastewater, waste gas, solid waste, etc. They are commonly used to treat wastewater treatment agents, garbage disposals, waste disposal, etc.

In addition to the above fields, screw mixers are also used in metallurgy, energy, agriculture, textile, paper and other industries. Their functions and characteristics make them one of the indispensable pieces of equipment in many industrial production processes.

A chemical company needs to mix a variety of powdered raw materials during the production process to meet product quality and process requirements. They chose a screw mixer as the mixing equipment. The screw mixer has efficient mixing capacity and uniformity, and can quickly mix raw materials with different particle sizes and specific gravity. By adjusting the screw speed and mixing parameters, they successfully achieved rapid mixing of raw materials and maintained product stability and consistency.

Dahan screw mixer manufacturer in Xinxiang City has the following advantages: First of all, it has rich experience and professional knowledge. It has been committed to the R&D and manufacturing of screw mixer for many years and has strong technical strength. Secondly, advanced production technology and high-quality materials are used to ensure product reliability and durability. In addition, Xinxiang Dahan screw mixer manufacturer focuses on innovation and continuously introduces advanced technology and equipment to improve product performance and efficiency. Finally, the company adheres to the principle of customer first and provides a full range of pre-sales and after-sales services to ensure customer satisfaction.

Choosing a suitable mixer requires combining the properties of the mixed materials, mixing requirements, equipment characteristics, etc.

Conical screw mixer: When selecting, the fluidity and stackability of the mixed materials should be considered. It is suitable for mixing powdered and granular materials, as well as materials that are easy to agglomerate or moist.

Horizontal screw mixer: Prioritize the viscosity, fluidity and specific gravity of the mixed materials, as well as the discharge method after mixing. It is suitable for mixing liquids, powders and granular materials.

Double screw mixer: It is used to mix viscous materials or high-viscosity materials. When selecting, consider the viscosity and fluidity of the materials, as well as the mixing method and speed of the mixer.

Dahan Machinery has many main products, including conical screw mixers, horizontal screw mixers, and double screw mixers. In terms of price, Dahan Machinery adheres to the principle of reasonable pricing, fully considering factors such as product cost, market competition, and customer acceptance, and formulates a competitive price system, generally $1,500.00-$6,000.00/Set. The specific price is also determined in combination with your different requirements for equipment specifications, functions, etc. You can contact us directly to obtain a detailed and accurate quotation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.