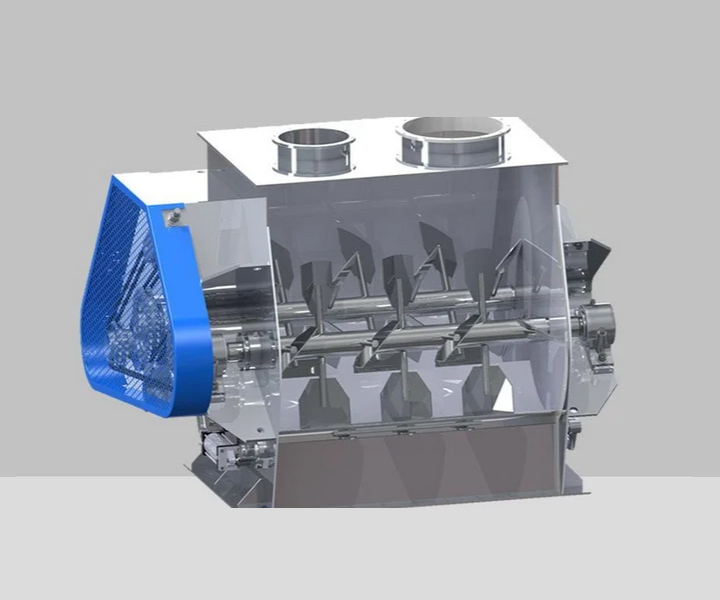

A device capable of efficiently mixing materials, achieving a uniform mixing effect through the rotational motion of the shaft and blades.

![]()

![]()

Price:$2,000.00-$20,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 300-3000kg

Mixing time: 8-20min

Voltage: 220V/380V/customize

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: It can be used to mix powder, granular, liquid and slurry materials. Including powder metallurgy, coatings, adhesives, and dyes; pharmaceutical powders, granules, and liquids in the pharmaceutical industry; flour, condiments, sauces, and jams in the food processing industry; cement, gypsum, and mortar materials in the building materials industry the mix of.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Twin shaft paddle mixer is a common industrial mixing equipment used to mix and stir different materials. It consists of two parallel shafts and paddles mounted on the shafts. The paddles are usually spiral-shaped. When the mixer is started, the two shafts rotate in opposite directions, and the paddles push and tumble the materials through rotational motion, thereby achieving uniform mixing of the materials. The twin shaft paddle mixer is suitable for mixing a variety of granular, powdery or liquid materials and is widely used in chemical, pharmaceutical, food and other industries.

The twin shaft paddle mixer has the characteristics of good mixing effect, uniform mixing and easy operation. Through the rotation of the blades, the materials can be fully mixed during the mixing process, so that materials with different components are evenly distributed, improving the quality and consistency of the product. The equipment has a compact structure, small footprint, strong adaptability, and can be customized according to different production needs. The twin shaft paddle mixer is simple to operate and maintain, and can improve production efficiency and work results. It is widely used in mixing and stirring processes in various industries.

The twin shaft paddle mixer has a wide range of uses and is mainly used in the following areas:

Mixing and stirring materials: The twin shaft paddle mixer is suitable for mixing and stirring materials with different ingredients to ensure the uniformity and consistency of the materials. It can be used to mix powdery materials, granular materials, liquid materials, and materials with different particle sizes, densities and properties.

Chemical industry: In chemical production, twin shaft paddle mixer is often used to mix chemical raw materials, pigments, dyes, coatings, adhesives, resins, etc. to ensure uniform reaction and stable product quality.

Pharmaceutical industry: In the pharmaceutical process, twin shaft paddle mixer is used to mix and stir pharmaceutical raw materials, pharmaceutical powders, pharmaceutical liquids, preparations, etc. to ensure uniform distribution and stability of pharmaceutical ingredients.

Food industry: In food production, twin shaft paddle mixer is often used to mix and stir food raw materials, seasonings, batters, sauces, etc. to ensure the consistency of food quality and uniformity of taste.

Building materials industry: In building materials production, twin shaft paddle mixer is used to mix and stir cement, mortar, paint, gypsum and other building materials raw materials to ensure the uniformity and quality stability of the materials.

Environmental protection industry: In environmental protection processes, twin shaft paddle mixer is often used to mix and stir wastewater treatment agents, sludge, solid waste, etc. to promote reactions and treatment effects and improve the efficiency of environmental protection processes.

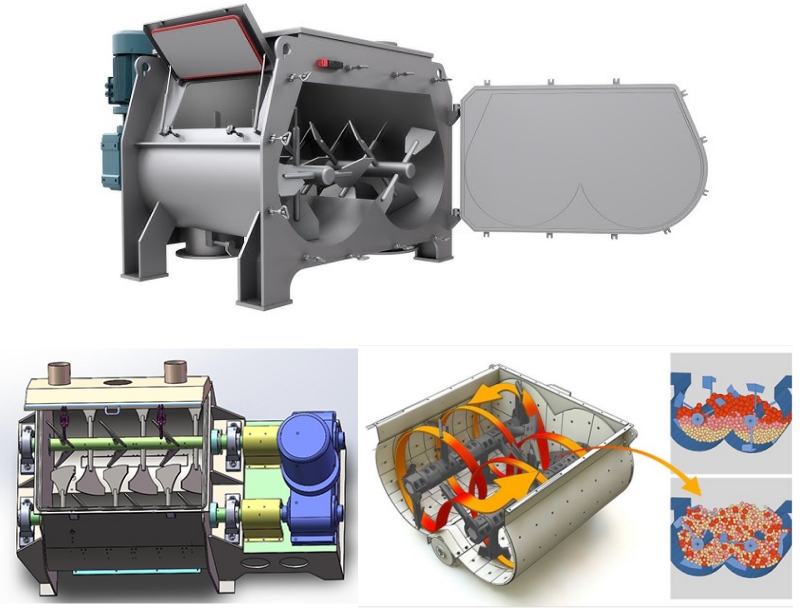

Twinshaft paddle mixer is an efficient mixing equipment, and different blade designs can achieve different mixing effects. Here are three common blade types:

| Flat Blades | Inclined Blades | Helical Blades |

|

|

|

| Flat blades are the most common type of paddle blade and are usually straight in shape and suitable for general mixing work. | The oblique blades are inclined, which is helpful for pushing the raw materials from the top to the bottom, and is suitable for occasions where rapid mixing and uniform mixing are required. | The spiral blades are designed in a spiral shape, which can effectively push the raw materials to all corners of the mixer, and are suitable for mixing liquids and powders. |

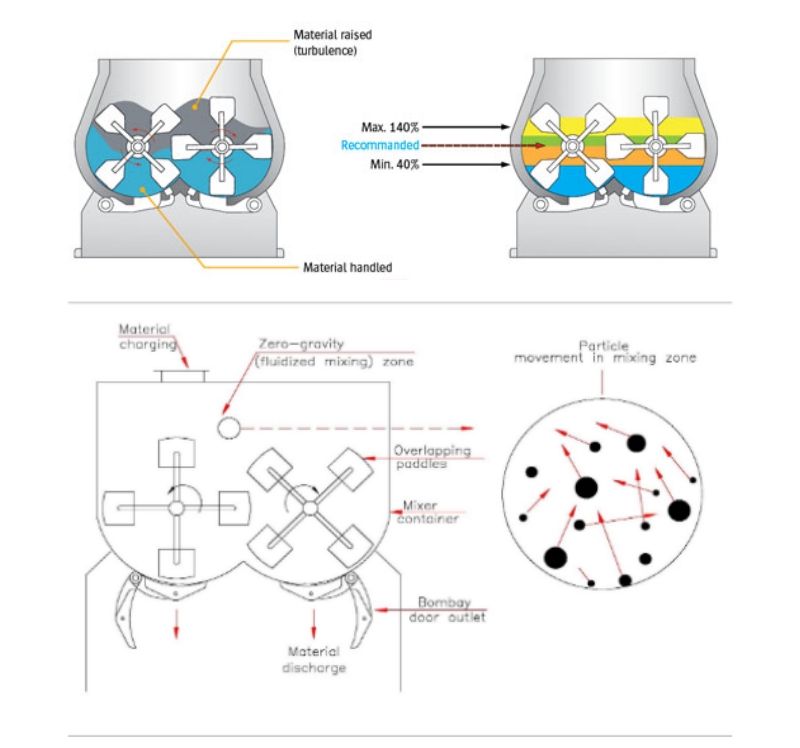

Twinshaft paddle mixers and singleshaft paddle mixers are two common mixing equipment, and they have some differences in structure and mixing effect. Here are their main differences:

| Twin Shaft Paddle Mixer VS Single Shaft Paddle Mixer | |

| Twin Shaft Paddle Mixer | Single Shaft Paddle Mixer |

|

|

| Structural design: Twinshaft paddle mixer has two horizontally rotating paddles, which are parallel to each other and arranged symmetrically. | Structural design: Single shaft paddle mixer has only one horizontally rotating paddle. |

| Mixing effect: Twinshaft paddle mixer can fully disperse the materials and continuously turn and cross them, thereby achieving higher mixing efficiency. | Mixing effect: The mixing effect of a single shaft paddle mixer is relatively weak, and the mixing time may take longer. |

| Scope of application: Twinshaft paddle mixer is suitable for mixing a variety of materials, including powdery materials, granular materials and some materials with a certain viscosity. | Scope of application: Single shaft paddle mixer is mainly suitable for mixing some powdery materials, such as chemical raw materials, powdery fertilizers, etc. |

| Equipment size: Twinshaft paddle mixers are usually relatively large and take up more space. Its mixing chamber has a large volume and can handle larger batches of materials. | Equipment size: Single shaft paddle mixers are generally smaller and suitable for small batch mixing needs. |

| Price and energy consumption: Twinshaft paddle mixers are generally more expensive. It requires more energy during the mixing process. | Price and energy consumption: The price of single shaft paddle mixer is relatively low and the energy consumption is also low. |

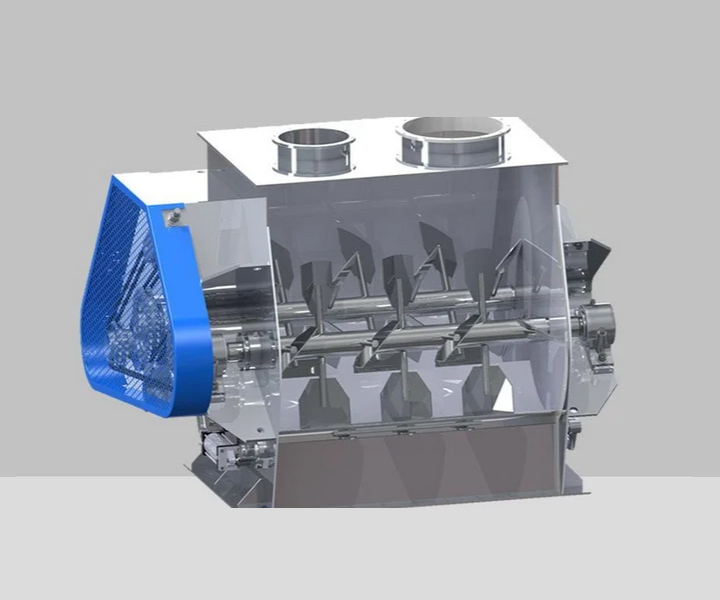

The working principle of the twin shaft paddle mixer is based on the rotational motion of the paddles, and the mixing and stirring of materials is achieved through the shear force and convection effect generated by the paddles on two parallel shafts. Here's a detailed description of how it works:

Structural composition: The twin shaft paddle mixer consists of two parallel shafts and paddles connected to the shafts. The shaft is usually driven by a motor, allowing the blades to rotate.

Paddle rotation: When the motor is started, the paddles on two parallel axes begin to rotate. The rotation direction of the paddles can be the same or opposite, depending on the requirements of the mixing process.

Shear and convection effects: The rotation of the blades produces shear and convection effects. Shear force is generated by the relative movement between the paddle and the material. It can cut, fold and stretch the material and promote the mixing of the material. The convection effect is the flow of materials caused by the rotation of the paddles, causing the materials to form a circular flow in the container, thereby achieving overall mixing and stirring.

Mixing effect: Through the rotation of the paddle, the material is continuously cut, folded, stretched and stirred in the container, thereby achieving uniform mixing of the material. The design and arrangement of the paddles can be adjusted according to different process requirements to obtain the required mixing effect.

Good mixing effect

The twin shaft paddle mixer can fully mix the materials through the rotation of the paddle and shear force, ensuring the uniformity and consistency of the mixing effect. It can effectively mix materials with different compositions, particle sizes and properties to improve product quality.

Easy to operate

The operation of the twin shaft paddle mixer is relatively simple. You only need to start the motor and adjust the rotation speed and mixing time. Operators only need to perform basic operations and monitoring, and no complex operating steps or professional skills are required.

Easy maintenance

The maintenance of the twin shaft paddle mixer is relatively simple, usually only requiring regular cleaning and lubrication maintenance. The design of the blades and shaft makes them easy to remove and install for repair and replacement.

Wide adaptability

The twin shaft paddle mixer is suitable for mixing and stirring a variety of materials, and can handle granular, powdery and liquid materials. It can be adjusted and customized according to different process requirements to suit the needs of different industries and application fields.

Short mixing time

Due to the efficient mixing principle of the twin shaft paddle mixer, it can complete the mixing process in a relatively short time. This helps improve production efficiency, shorten production cycles, and reduce production costs.

High reliability

The twin shaft paddle mixer is made of sturdy and durable structural design and high-quality materials, with high reliability and stability. It can run stably for a long time and is not prone to failure, ensuring the continuity and stability of the production process.

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

The twinshaft paddle mixer is an important mixing equipment, mainly used to uniformly mix different materials. Its function can be summarized as follows:

Uniform mixing: Cutting, folding and cross-mixing different materials to achieve uniform mixing of materials. Whether it is powdery material or granular material, the twinshaft paddle mixer can mix it very evenly.

Improve mixing efficiency: The twinshaft paddle mixer uses two horizontally rotating paddles. The rotation of the paddles shears and mixes the materials, allowing the materials to fully contact and mix quickly.

Improve product quality: Mixing is a very important part of the production process. The twinshaft paddle mixer can fully mix different materials to ensure that each particle or powder is in full contact with other materials, thereby improving the uniformity and consistency of the product.

Improve production efficiency: The twinshaft paddle mixer has the characteristics of efficient mixing and uniform mixing, and can quickly and thoroughly mix materials evenly. This helps reduce mixing time and improve production efficiency.

A chemical company needs to mix a variety of powdered raw materials during the production process to ensure product quality and consistency. To meet this demand, they chose a twin shaft paddle mixer as the mixing equipment. The mixer has the characteristics of efficient mixing effect and easy operation, and can evenly mix raw materials with different compositions and particle sizes. After communication and understanding with the customer, the mixer parameters and paddle design were customized to suit the customer's specific process requirements. By using the twin shaft paddle mixer, the chemical company successfully achieved rapid mixing of raw materials, shortened the production cycle, improved production efficiency, and achieved consistent product quality.

Xinxiang Dahan twin shaft paddle mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the twin shaft paddle mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The twin shaft paddle mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan twin shaft paddle mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy twin shaft paddle mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.