Twin shaft paddle mixer is a common mixing equipment used to uniformly mix different materials. Its structural design mainly includes mixing chamber, paddle, transmission device, discharge port and other components. The following is a detailed structural introduction of the twin shaft paddle mixer:

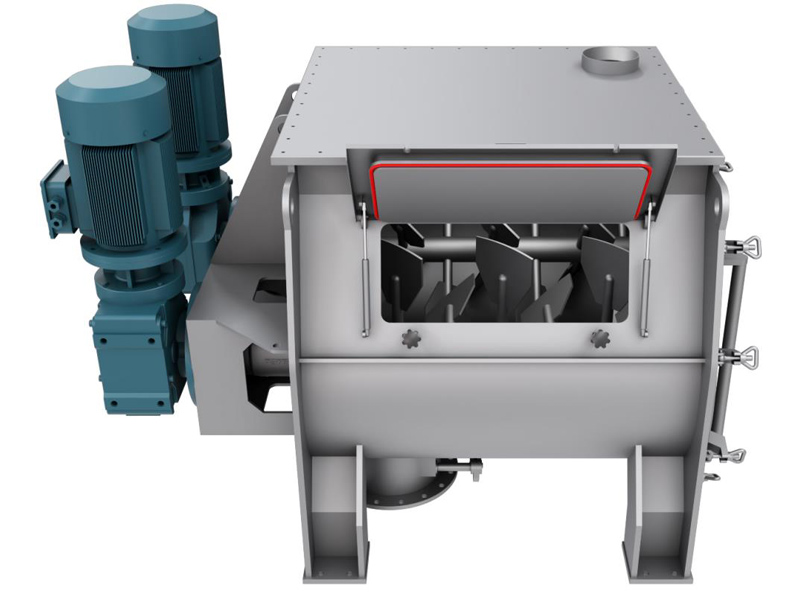

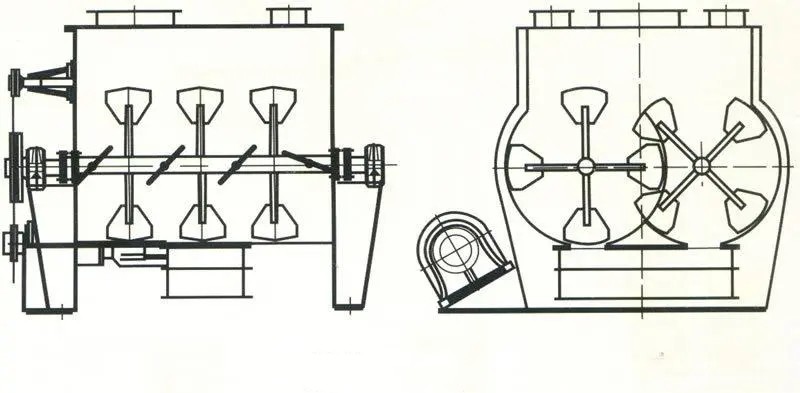

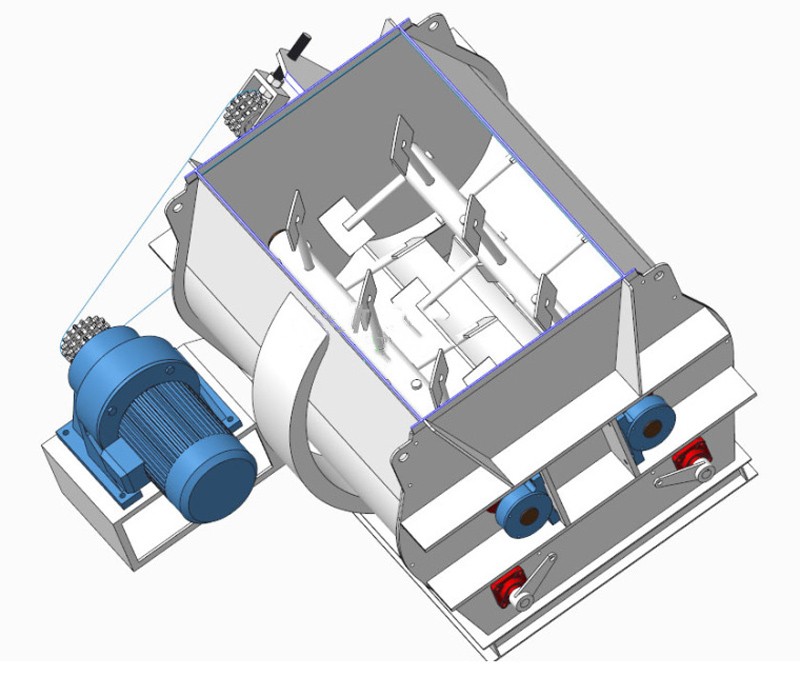

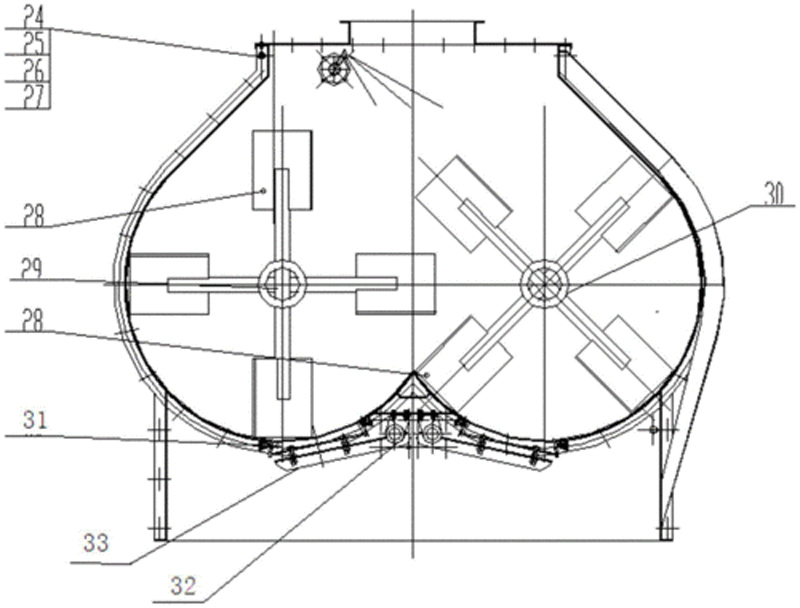

The mixing chamber of the twin shaft paddle mixer is a closed container used to contain the materials to be mixed. The mixing chamber is usually welded from steel plates and has sufficient strength and sealing properties. Its shape can be cylindrical, square or oval, depending on the specific design and application needs. The inside of the mixing chamber usually has smooth inner walls to reduce adhesion and accumulation of materials.

Twin shaft paddle mixers are usually equipped with two or more horizontally rotating paddles. The paddles are fixed on the two horizontal axes of the mixing chamber and are located inside the mixing chamber. The shape and layout of the paddles can be designed according to the mixing requirements. Typically, the paddles are rectangular or trapezoidal in shape to increase the mixing effect. The length and width of the paddle can also be adjusted according to the size of the mixing chamber and material characteristics.

The transmission device of the twin shaft paddle mixer is used to drive the rotation of the paddles. The transmission device usually consists of a motor, a reducer and a coupling. The motor provides power, and the reducer reduces the speed of the motor and transmits the power to the blades through the coupling. The transmission is usually located outside the mixing chamber to facilitate maintenance and service.

The discharge port of the twin shaft paddle mixer is used to discharge the mixed materials. The outlet is usually located at the bottom of the mixing chamber and can be open or have a discharge valve. The open outlet is suitable for materials with good fluidity, while the outlet with a discharge valve can better control the flow and discharge of materials.

The twin shaft paddle mixer may also include other components, such as feed ports, observation windows, cleaning ports, etc. The feed port is used to put materials into the mixing chamber, the observation window is used to observe the mixing process, and the cleaning port is used to clean the mixing chamber and paddles.

Overall, the structural design of the twin-shaft paddle mixer is simple and compact, with a reasonable layout and functional components. The mixing chamber, paddles, transmission device and discharge port are its main components, and they work together to achieve uniform mixing of materials. This structural design enables the twin shaft paddle mixer to have the characteristics of efficient mixing, uniform mixing, multi-functional operation, durability, reliability and wide applicability. It is widely used in feed processing, chemical industry, metallurgy, building materials and other industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.