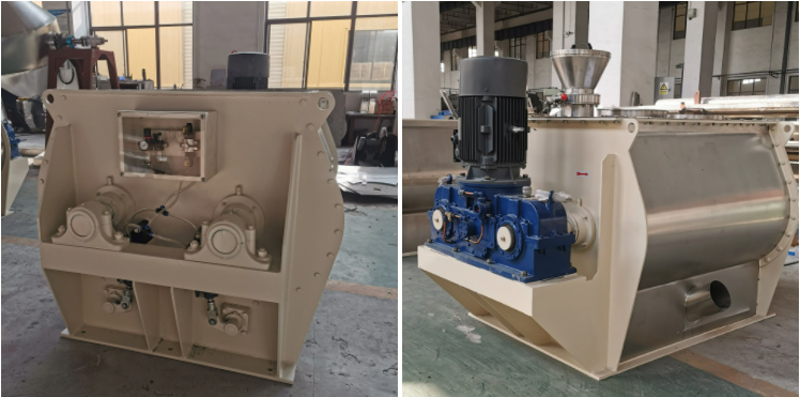

Continuous twin shaft paddle mixers are an industrial mixing equipment used to mix and stir materials. It consists of two rotating shafts and paddles mounted on the shafts. Through the movement of the paddles, the materials are sheared, staggered and collided to achieve uniform mixing. Different from traditional batch mixers, continuous mixers have the ability of continuous feeding and continuous discharging, and are suitable for large-scale continuous production. It is widely used in chemical, pharmaceutical, food, building materials and other industries. It has the characteristics and advantages of efficient continuous mixing, uniform mixing quality, flexible process adjustment, saving space and manpower, etc.

The working principle of the continuous twin shaft paddle mixer is basically similar to the traditional twin-shaft paddle mixer. The materials are mixed and stirred through two rotating shafts and paddles installed on the shafts. The difference is that the continuous mixer has the ability of continuous feeding and continuous discharging, and is suitable for large-scale continuous production. Materials continuously enter the mixer through the feed port, and are continuously discharged from the discharge port after being stirred and mixed by the paddles. This continuous operation greatly improves production efficiency.

Efficient continuous mixing: Continuous twin shaft paddle mixers can achieve continuous material feeding and discharging, greatly improving mixing efficiency and production capacity.

Uniform mixing quality: The rotation and interaction of the twin-shaft blades enable the materials to fully stagger and collide, achieving uniform mixing and ensuring consistent product quality.

Flexible process adjustment: Continuous twin shaft paddle mixers are usually equipped with adjustable speed and feed volume control devices, which can be flexibly adjusted and optimized according to process requirements.

Save space and manpower: Compared with batch mixers, continuous mixers take up less space and do not require frequent loading and unloading of materials, reducing labor costs.

Automated control: Continuous twin shaft paddle mixers can be integrated with automated production lines to achieve automated control and monitoring, improving production efficiency and stability.

Continuous twin shaft paddle mixers are widely used in many industries, including but not limited to the following fields:

Chemical industry: Continuous twin shaft paddle mixers are used for mixing large quantities of chemical raw materials, such as pigments, coatings, adhesives, etc.

Pharmaceutical industry: Continuous twin shaft paddle mixers are suitable for continuous mixing processes such as preparing drugs and pharmaceutical intermediates.

Food industry: Continuous twin shaft paddle mixers are used for large-scale continuous mixing of food raw materials, such as feed, seasonings, candies, etc.

Building materials industry: Continuous twin shaft paddle mixers are suitable for continuous mixing of cement, mortar and other building materials.

Powder metallurgy industry: Continuous twin shaft paddle mixers are used in powder metallurgy processes such as continuous mixing of metal powders and ceramic powders.

When a chemical company produces a certain pigment, it requires continuous mixing in large batches. They chose a continuous twin shaft paddle mixer as the key equipment. The mixer has efficient continuous operation capabilities to meet their production needs. Through the stirring and mixing action of the mixer, the ingredients of the pigment are fully and evenly mixed, ensuring the stability of product quality. At the same time, the automatic control system of the continuous mixer makes the entire production process more stable and reliable. By using a continuous twin shaft paddle mixer, this chemical company has improved production efficiency, reduced labor costs, and achieved significant economic benefits.

To sum up, the continuous twin shaft paddle mixer achieves efficient continuous mixing through continuous material feeding and discharging. It has the characteristics and advantages of uniform mixing quality, flexible process adjustment, saving space and manpower, and automatic control. It has a wide range of applications in the fields of chemical industry, pharmaceuticals, food processing, building materials and powder metallurgy.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.