Food grade stainless steel paddle mixer is a key equipment in the food processing industry, used to mix food raw materials to ensure food quality and safety. This mixer is made of food grade stainless steel, fully automatic mixing, has the advantages of corrosion resistance, easy cleaning, etc., and complies with food safety standards. The design structure of the food grade stainless steel paddle mixer is very important. It usually consists of a paddle mixing device, which uses rotating motion to evenly mix food ingredients. This design ensures that the various ingredients in the food are fully mixed, improving the quality and taste of the food.

The food-grade stainless steel paddle mixer uniformly mixes food ingredients through the rotation of the paddles. When food ingredients are placed into the mixer, the paddles begin to rotate, pushing the ingredients to all corners of the mixing chamber to ensure that each part is fully mixed. This efficient mixing method can improve production efficiency, reduce mixing time, and reduce production costs.

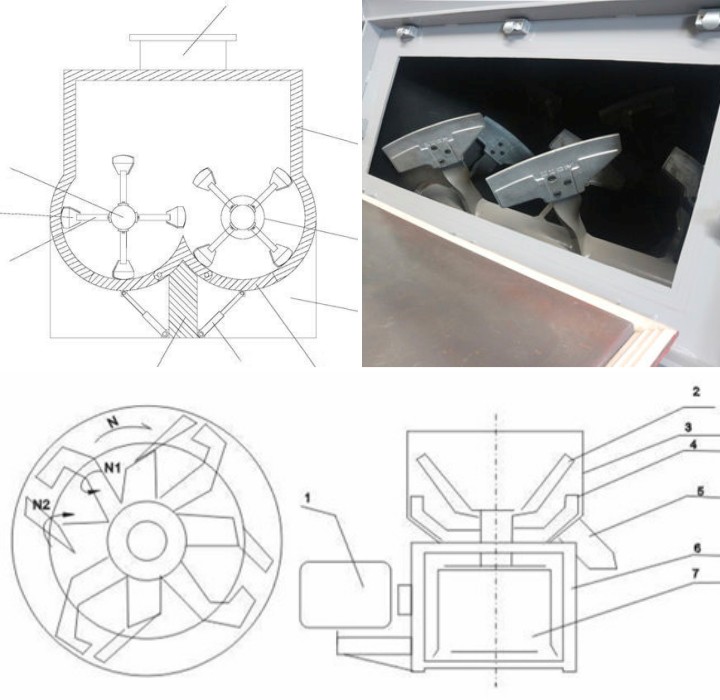

The paddle mixer uses rotating paddles to produce mechanical action in the container, so that materials of different components can be fully mixed. According to the characteristics of different food raw materials and mixing requirements, the design of the paddles is also diverse.

Flat paddle mixer: simple structure, suitable for mixing low viscosity liquids, promoting uniform overall flow.

Oblique paddle mixer: produces a certain axial flow, suitable for mixing medium and low viscosity liquids and stirring suspensions.

Bent paddle mixer: has stronger shear force, suitable for mixing needs such as dispersion and emulsification, and also suitable for liquids with higher viscosity.

Frame mixer: suitable for mixing high viscosity liquids and paste materials, and can effectively prevent materials from sticking to the wall.

Anchor mixer: the shape is similar to the inner wall contour of the container, suitable for mixing and heat transfer of high viscosity materials.

Propeller mixer: produces strong axial flow, suitable for rapid mixing and circulation of low viscosity liquids.

Food grade stainless steel paddle mixers usually consist of mixing barrels, motors, transmissions, paddles and other components. The mixing barrel is used to contain food ingredients. The motor provides power to drive the paddles to rotate. The transmission device transmits the power of the motor to the paddles, and the paddles are responsible for mixing the food ingredients.

Mixing tank: food grade stainless steel 304 or 316L, the structure can be designed into round, square, conical, etc. according to needs.

Paddle: food grade stainless steel material, various shapes (such as flat paddle, inclined paddle, frame, etc.), can be selected according to material characteristics.

Transmission system: The motor is used to provide power to drive the stirring shaft to rotate. Reducer, reduce the motor speed and increase the torque.

Support frame: Support the mixing tank, transmission system and other components to keep the equipment stable.

Base: Fix the equipment to prevent the equipment from moving.

Electric control cabinet: Control the start, stop, speed, etc. of the motor.

Inverter: Adjust the motor speed to meet the mixing requirements of different materials.

Feed port: Used to add materials.

Discharge port: Used to discharge the mixed materials.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Food grade stainless steel material: Made of food grade stainless steel material, it is corrosion-resistant, easy to clean, and complies with food safety standards.

Uniform mixing: The rotating motion of the paddle ensures that food ingredients are fully mixed, improving food quality and taste.

Simple operation: easy to operate, clean and maintain, improving production efficiency.

Widely used: widely used in food processing, pharmaceuticals, cosmetics and other industries.

Food processing industry: used to mix flour, powdered sugar, seasonings, etc., to produce bread, pastries, candies and other foods.

Pharmaceutical industry: used to mix pharmaceutical raw materials to ensure uniform pharmaceutical ingredients.

Cosmetics industry: used to mix cosmetic raw materials and produce various cosmetic products.

Other industries: It can also be used to mix raw materials in other fields, such as chemical industry, agriculture and other fields.

In general, food grade stainless steel paddle mixers play an important role in the above application scenarios, providing efficient mixing solutions for production in different industries. Our Dahan manufacturer produces different types of paddle mixers that can meet any of your needs. The maximum one-time mixing volume is 3000kg. If you need this type of paddle mixer, you can click on the website page for consultation, and we will develop a detailed plan for you.

Food grade stainless steel paddle mixer can select the appropriate paddle type according to the specific application scenario, so as to achieve efficient mixing of various food raw materials.

Powder and powder mixing: such as flour, milk powder, powdered sugar, spices, etc.

Liquid and liquid mixing: such as beverages, soy sauce, vinegar, cooking oil, etc.

Solid and liquid mixing: such as juice and pulp, syrup and additives, suspension of solid particles in liquid, etc.

Paste material mixing: such as dough, fillings, jam, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.