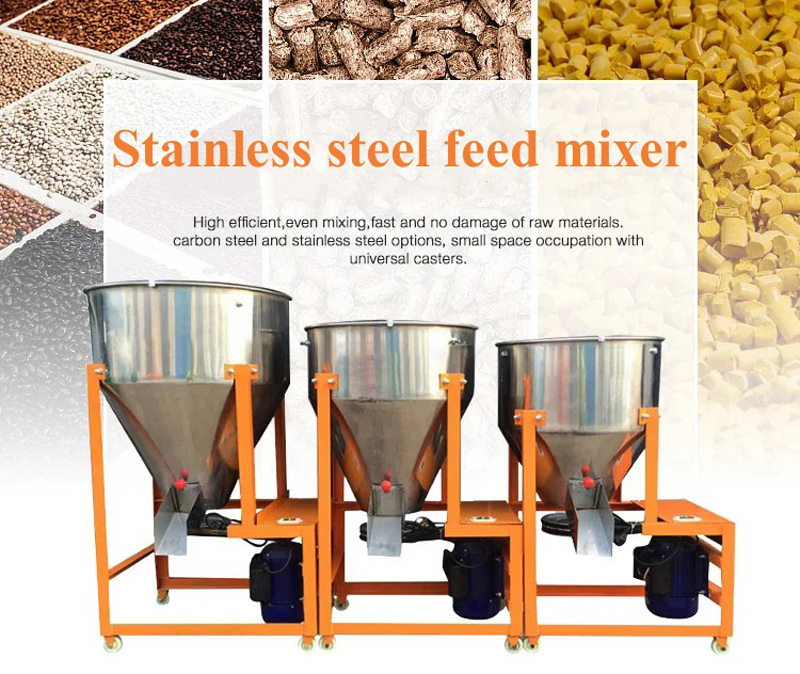

Made of high-quality stainless steel, it is corrosion-resistant, easy to clean and hygienic, and is used to mix various feed ingredients into a homogeneous mixture

![]()

![]()

Price:$1,500.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Material: SUS304, SUS304L, SUS316, SUS316L

One-time mixing: 100-6000 (kg)

Mixing time: 8-20min

Capacity: Up to 1000 Liter

Voltage: 380V (Can be specially customized according to customer requirements)

Frequency: 50 Hz、60HZ

Application: Feed ingredients such as grains, proteins, vitamins, minerals, fats, syrups, and feed additives can be mixed.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Stainless steel feed mixers are usually made of stainless steel because it is durable, corrosion-resistant and easy to clean. They are often used in agricultural and breeding environments to mix various types of animal feed to provide animals with balanced and nutritious feed.

The stainless steel construction of these mixers ensures that the feed remains uncontaminated and meets hygiene standards. The mixing process helps to create a uniform blend of ingredients, ensuring that animals receive a balanced diet with each feeding. A variety of sizes are available to suit different production scales from small farms to large feed mills.

Stainless steel feed mixers are indispensable equipment in the feed processing industry. They are of various types and have their own characteristics. According to different structures, working principles and application ranges, stainless steel feed mixers can be divided into the following categories:

1. Classification by mixing principle

Paddle mixer: uses paddles for mixing, suitable for viscous or wet feed ingredients, and has good mixing effect.

Screw mixer: uses spiral structure for mixing, suitable for granular and powdered materials, with high efficiency.

Ribbon mixer: through belt conveying and mixing, it is suitable for large-scale feed production.

Vertical mixer: the mixing trough is placed vertically, suitable for small batch mixing, and has a compact structure.

2. Classification by capacity

Small mixer: suitable for small farms, family farming, and small-scale feed production, with small capacity and easy to move, mixing 50-500 kg per batch.

Medium mixer: suitable for medium-sized farms and small feed factories, with moderate capacity, mixing 500-2000 kg per batch.

Large mixer: used in large feed mills, with strong processing capacity, suitable for large-scale production, mixing 2000-6000 kg per batch.

Livestock Feed: Used for blending feed for cattle, pigs, poultry, and other livestock.

Pet Food Production: Ideal for mixing ingredients in the production of pet food.

Aquaculture: Utilized in the preparation of feed for fish and other aquatic animals.

Specialty Feeds: Can be used for producing specialty feeds, such as organic or medicated feeds.

Versatility

Mixing grains, proteins, vitamins, minerals, and other feed ingredients to create a balanced and nutritious feed for livestock.

Uniform Mixing

Ensuring a consistent blend of ingredients to prevent selective eating by animals and to promote even distribution of nutrients.

Hygiene

Stainless steel surfaces are non-porous and easy to clean, preventing the buildup of bacteria and other contaminants that can compromise feed quality and animal health.

Food Safety

Stainless steel is widely recognized as a safe material for food processing and handling, ensuring that the feed produced meets the highest standards of quality and safety.

Durability

Stainless steel is known for its strength and resistance to corrosion, making it a long-lasting choice for feed mixing equipment.

Corrosion Resistance

Stainless steel is naturally resistant to rust and oxidation, even in environments with high humidity and exposure to moisture.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Mixer Body:.This is the main structure of the mixer, usually made of stainless steel to ensure durability and hygiene. It can be horizontal, vertical, or a combination of both.

Mixing Blades or Paddles: These are the rotating elements within the mixer that agitate and blend the ingredients. They can be various shapes, such as paddles, screws, or planetary gears, depending on the mixer type.

Drive Mechanism: This system powers the mixing blades or paddles. It typically consists of a motor, gearbox, and transmission shafts.

Loading and Unloading Ports: These openings allow for the entry of ingredients and the removal of the finished feed. They can be located at the top, bottom, or sides of the mixer.

Control Panel: This panel contains switches, buttons, and displays for operating the mixer. It may include features like variable speed control, timer settings, and safety interlocks.

Additional Features (May Vary):

Material: Made from high-quality stainless steel, which is resistant to corrosion, easy to clean, and hygienic.

Mixing Mechanism: Typically employs paddle, ribbon, or screw mixing mechanisms to ensure thorough blending of ingredients.

Capacity Options: Available in various sizes to accommodate different production scales, from small farms to large feed mills.

User-Friendly Design: Often equipped with access doors for easy loading and unloading, as well as maintenance.

Control Systems: May include advanced control systems for precise ingredient measurement and mixing times.

Dust Collection System: To capture and filter dust particles generated during the mixing process.

Safety Features: Emergency stop buttons, safety guards, and interlocks to prevent accidents.

Mixing time selection

Fast mixer: The mixing time is shorter, generally about 8 minutes, or even shorter. Slow mixer: The mixing time is longer, generally about 15-20 minutes.

Volume size selection

Small feed mixer: Small volume, one-time mixing is less than 1000kg, suitable for family farming or small feed processing plants. Large feed mixer: Large volume, one-time mixing is about 3000kg, suitable for large feed processing plants or large farms.

Selection of mixing shaft number

Single-shaft mixer: There is only one mixing shaft, simple structure, low price, suitable for mixing a small amount of feed.

Double-shaft mixer: With two mixing shafts, the mixing efficiency is higher and the uniformity is better, suitable for mixing a large amount of feed.

Control mode selection

Manual control: The mixer is controlled by manual operation buttons, low price, suitable for small mixers.

Automatic control: The mixer is controlled by PLC or microcomputer, easy to operate, suitable for large mixers.

Additional functions

Heating function: It can be used to mix feed that needs to be heated. Cooling function: can be used to mix feed that needs to be cooled. Weighing function: can be used to accurately control the mixing ratio. Dust removal function: can effectively remove dust during the mixing process.

304 +Good Workmanship

Our machine are made of food grade stainless steel 304,fulling welding and polishing

Mirror Polishing +Safety Grid

The inside of the tank of our machine uses a mirror polishing,food grade workmanship

It is easy to clean.

A certain breeding farm is a large-scale livestock breeding enterprise focusing on pork production. They face several challenges during the feed mixing process, including uneven mixing, long mixing times, and high energy consumption. In order to improve feed quality and production efficiency, they decided to introduce a stainless steel feed mixer. Before introducing the stainless steel feed mixer, the farm conducted on-site research and equipment selection. They then worked with the supplier to install, commission and train the equipment. Farm staff received operational training and mastered the use and maintenance of the mixer.

The farm has seen significant improvements since the introduction of stainless steel feed mixers. The uniformity of feed mixing is greatly improved, ensuring the consistency of various ingredients in the feed and improving the animal's utilization of feed. The mixing time is greatly shortened, saving production time and energy consumption. In addition, the use of stainless steel materials ensures the hygiene and safety of feed and helps improve the health of animals.

| Customer name | Mixed feed | Applications | Mixing time | Mixing quantity per time | Other requirements |

| A large feed factory | Corn, soybean meal, fish meal, vitamins, minerals | Pig feed | 3-5 minutes | 5 tons | High uniformity, no dead angle mixing |

| A small farm | Corn, wheat, bran, bone meal | Poultry feed | 2-3 minutes | 1 ton | Quick mixing to ensure freshness |

| A pet food factory | Meat meal, grains, vegetables, vitamins | Pet dog food | 5-8 minutes | 500 kg | Even mixing, no dust pollution |

| A fish farm | Fish meal, soybean meal, vitamins, minerals | Aquatic feed | 4-6 minutes | 2 tons | Even mixing to prevent caking |

When choosing a stainless steel feed mixer, in addition to considering the mixing amount, you also need to consider the following factors:

Material properties: Different materials have different requirements for mixers, such as powdered materials, granular materials, sticky materials, etc.

Mixing uniformity: For materials with high requirements for mixing uniformity, you can choose a mixer with better mixing effect.

Production efficiency: Choose a mixer with high production efficiency according to production needs.

Automation degree: Choose the corresponding mixer according to the requirements of production scale and automation degree.

Budget: The prices of different models of mixers vary greatly, and you need to choose the right equipment according to your budget.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.