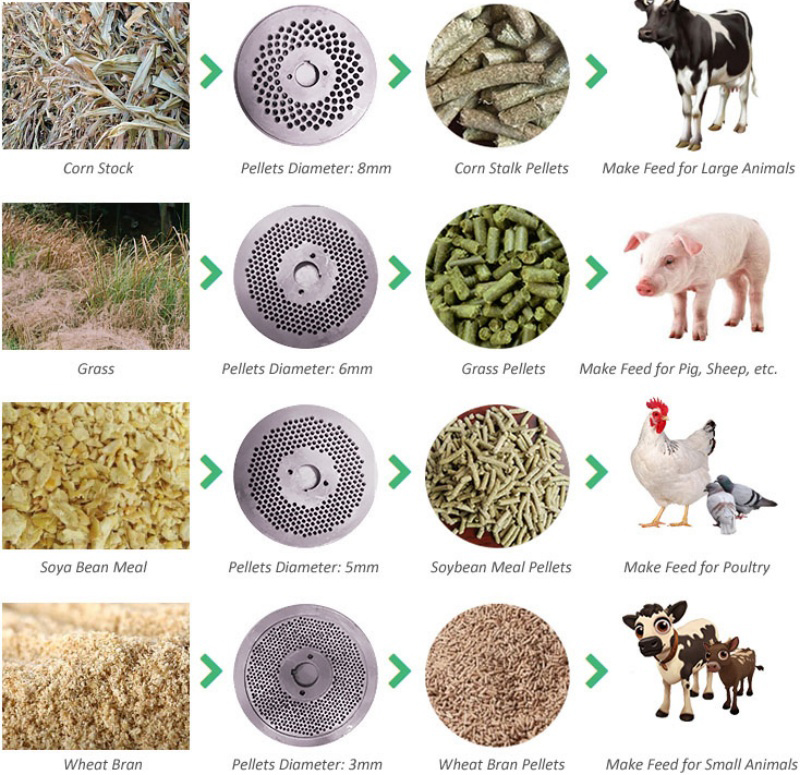

The particle size is adjustable and a variety of feed pellets can be easily produced.

![]()

![]()

Price::$180.00 - $285.00/Set

Consult now and enjoy a 10% discount

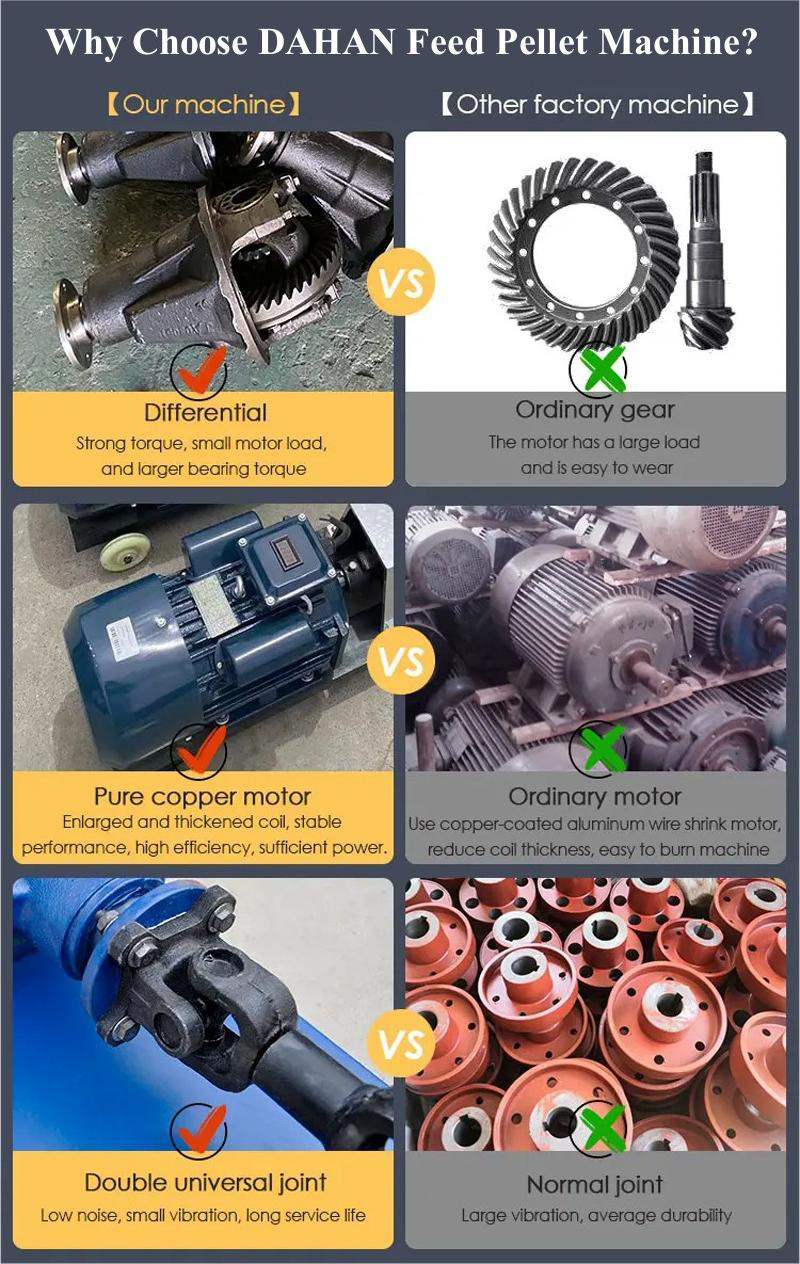

Core Components: Gear, Motor

Max. Capacity: 200KG/H

Feed Capacity: 60-100kg/h

Voltage: 220V/380V

Pellet size: 5-50mm

Dimension(L*W*H): Customize

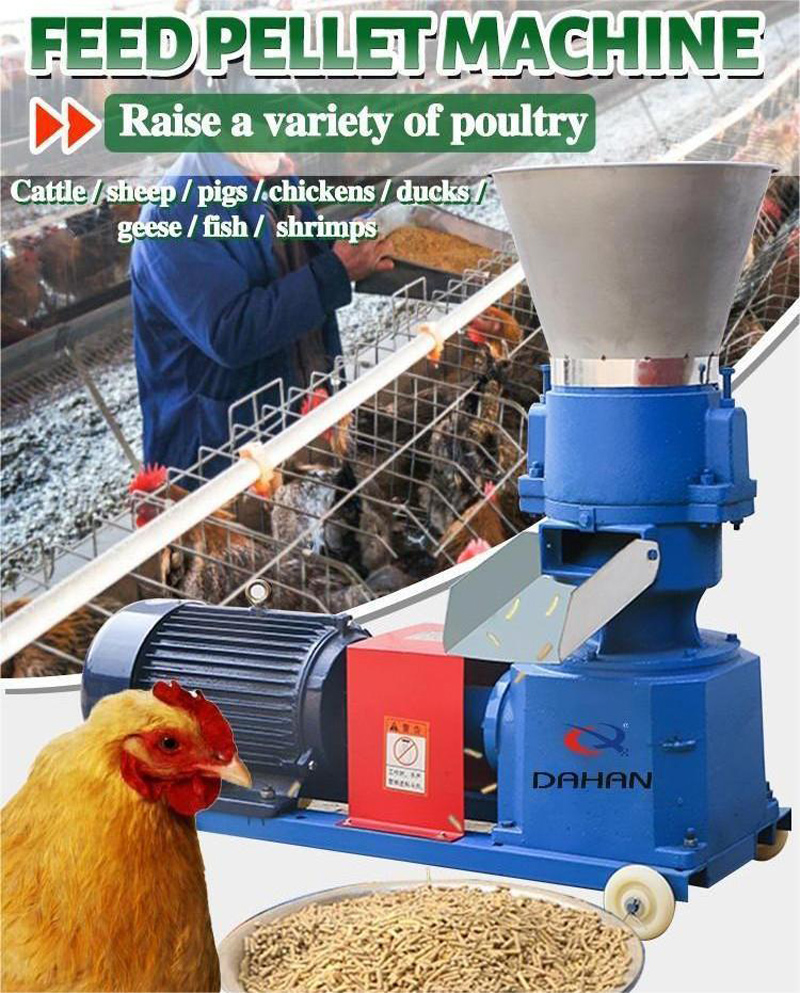

Application:can directly extrude feed, corn, soybean meal, rice husk, straw and grass into small pellets.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Feed pellet machine is a special equipment used to process feed raw materials into granular form. It processes the feed raw materials, including crushing, mixing, conditioning and other processes, and then uses mechanical extrusion, shearing and friction to press the feed raw materials into particles with certain specifications and shapes. It consists of a feeding device, a pressing device, a tempering device, a transmission system and a control system.

Feed pellet machines have a wide range of applications, mainly in the livestock breeding industry. They can process a variety of feed raw materials, including grains, soybean meal, fish meal, bone meal, etc., to make pellet feed suitable for different animals. Pellet feed has the advantages of uniform ingredient distribution, easy digestion and absorption, reduced waste and reduced environmental pollution. In addition, pellet feed is easy to store and transport, which improves feed utilization and production efficiency.

When it comes to the different types of feed pellet machines, the three common types include electric feed pellet machines, diesel feed pellet machines, and gasoline feed pellet machines.

Electric feed pellet machine: The electric feed pellet machine is driven by an electric motor as a power source. Because the motor has low power and speed, it is usually used to process small batches of feed pellets, such as feed processing for poultry, rabbits, etc.

Diesel feed pellet machine: The diesel feed pellet machine is driven by a diesel engine as a power source. It has high power and rotation speed and is suitable for small and medium-sized farms or farms. Diesel feed pellet machines can handle large quantities of feed ingredients.

Gasoline feed pellet machine: The gasoline feed pellet machine is driven by a gasoline engine as the power source. Gasoline engines have smaller power and higher speed, making them suitable for small farms or farms. Usually small in size and portable, easy to carry and move.

Feed pellet machine is a kind of mechanical equipment widely used in livestock and poultry breeding industry. Its main function is to process powdery feed raw materials into granular or lumpy finished feed.

The feed pellet machine has the following application scenarios:

Poultry farms: In poultry farms, feed pellet machines are mainly used to process animal feeds such as chicken feed, duck feed, goose feed, pig feed, and cattle feed. Pelleted feed is easier for livestock to swallow and digest, and is less likely to be wasted.

Aquaculture farms: In aquaculture farms, feed pellet machines are mainly used to process fish feed, shrimp feed, crab feed, etc. Pelleted feed is more suitable for the feeding habits of aquatic animals and is less likely to pollute water quality.

Pet feed factory: In pet feed factories, feed pellet machines are mainly used to process cat food, dog food, rabbit food, bird food, etc. Pelleted pet feed is easy to store and transport, and is more popular with pets.

Biomass power plant: In biomass power plants, feed pellet machines are mainly used to process biomass waste such as straw, wood chips, and rice husks. Pelleted biomass fuel is easier to burn and has a higher calorific value, making it a clean and renewable energy source.

Feed processing plant: In feed processing plants, feed pellet machines are mainly used to process various animal compound feeds. Pelleted animal feed is easier to store and transport, and is more suitable for digestion and absorption by livestock.

In practical applications of feed pellet machines, different models and specifications of equipment can be selected according to different needs to meet different processing requirements.

The working principle of feed pellet machine mainly includes two steps: extrusion and cutting. Details as follows:

Extrusion: The feed pellet machine sends feed raw materials into the extrusion chamber through the feeding system. In the extrusion chamber, the feed materials are gradually pushed forward by the rotating extrusion screw. During the advancement process, the feed raw materials are affected by extrusion force and friction, and the temperature and pressure gradually increase. This causes the starch and protein in the feed ingredients to gelatinize and form a certain cohesive force.

Cutting: When the feed material is pushed to the exit of the extrusion chamber, it encounters a rotating cutting knife or die. A cutting knife or die will cut the extruded feed ingredients into pellets. The form of cutting can be rotary cutting or pressure cutting, depending on the design of the feed pellet machine. The cut granular feed is discharged through the discharge port to complete the entire processing process.

Improve feed utilization

The feed pellet machine processes feed raw materials into granular feed, which can improve the density and stability of the feed, thereby improving feed utilization.

Easy to store and transport

The feed pellet machine can process and improve feed raw materials, causing the starch and protein in the feed to gelatinize.

Reduce feed pollution

Pelleted feed has high density and stability, making it easy to store and transport. Compared with bulk feed, pelleted feed can save storage space.

Stable equipment

The pelletized feed processed by the feed pellet machine can reduce feed dust and impurities and reduce the degree of feed pollution.

Improve production efficiency

It has high processing capacity and efficiency, continuously processes feed, improves production efficiency, and reduces labor input and energy consumption.

Adapt to different needs

It can be processed according to the feeding needs of different animals, and the size, shape and composition of the particles can be adjusted to meet the nutritional needs of different animals.

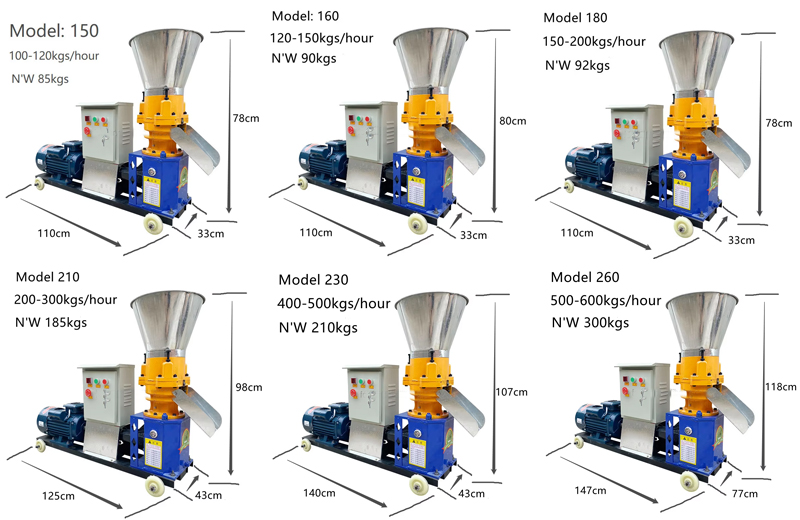

| Type | Power | Output (kg/h) | Weight (kg) | Package Size (mm) |

|---|---|---|---|---|

| ZLSP 120B | Three phase 3kw / single phase 2.2kw | 60-100 | 80/100 | 750x320x680 |

| ZLSP 150B | Three phase 4kw | 90-120 | 95/110 | 800x450x700 |

| ZLSP 200B | Three phase 7.5kw | 200-300 | 200/230 | 1650x820x1200 |

| ZLSP 230B | Three phase 11kw | 300-400 | 290/320 | 1050x480x930 |

| ZLSP 260B | Three phase 15kw | 400-600 | 320/360 | 1180x540x1000 |

| ZLSP 300B | Three phase 22kw | 600-800 | 350/380 | 1240x540x950 |

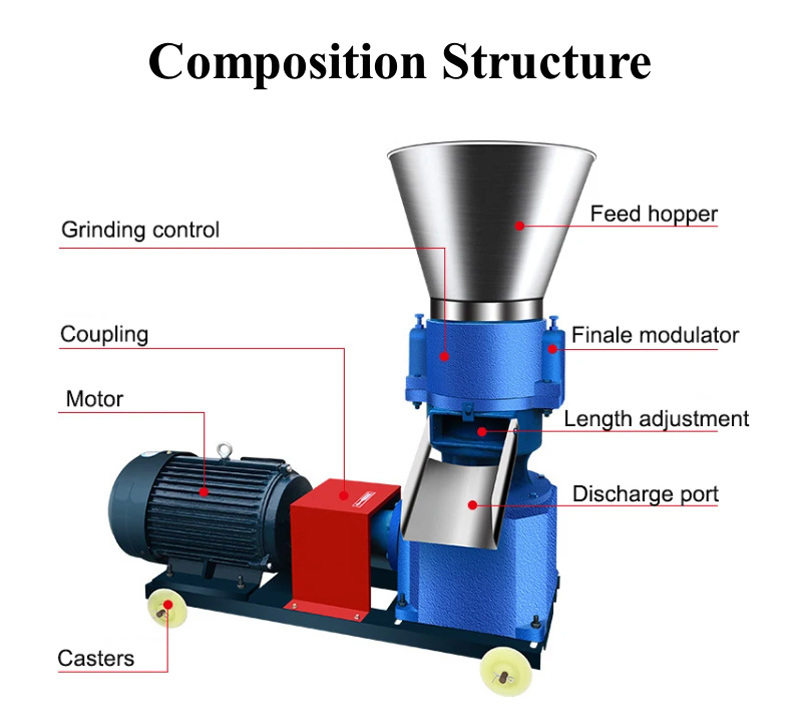

The structure of a feed pellet machine usually includes a host machine, a feeding system, a feeding system, a transmission system, a cooling system and a control system.

Main machine: It consists of a frame, spindle, roller, mold plate, etc. It is the core component of the feed pellet machine and is responsible for pressing raw materials into pellets.

Feeding system: It consists of a feeding hopper, a feeding roller, a feeding spiral, etc., and is responsible for transporting raw materials to the host machine.

Transmission system: composed of motor, pulley, sprocket, etc., responsible for transmitting power to the host machine.

Cooling system: It consists of fans, radiators, etc., and is responsible for dissipating the heat generated by the host.

Control system: It consists of an electric control box, buttons, instruments, etc., and is responsible for controlling the operation of the feed pellet machine.

Choosing the right feed pellet machine requires considering multiple factors to ensure that the equipment can meet production needs and operate efficiently. The following are key points when choosing a feed pellet machine:

Output requirements: Small farms can choose equipment with an output of tens of kilograms per hour, while large feed mills require high-capacity machines with a capacity of several tons per hour.

Raw material types: Different raw materials (such as corn, soybean meal, grass meal, etc.) have different physical properties, and you need to choose a pellet machine suitable for processing these raw materials.

Raw material moisture: Too high or too low raw material moisture will affect pellet formation, so choose equipment that can adapt to different moisture contents.

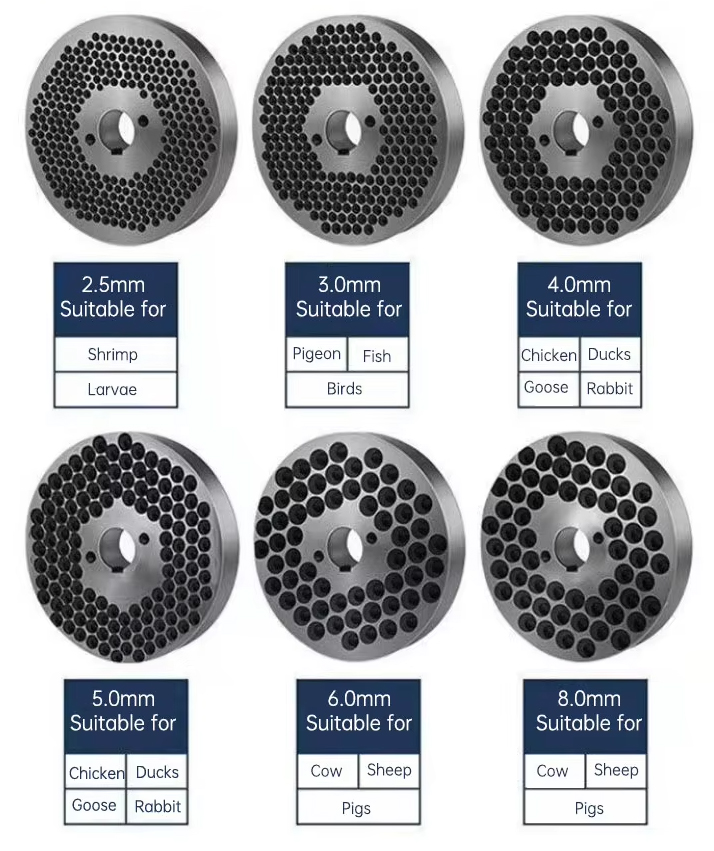

Mold aperture: Choose the appropriate mold aperture according to the animal species and growth stage to ensure the appropriate particle size. Common apertures are 2-12 mm.

1. Material

The material of the feed pellet machine directly affects the service life of the equipment and the quality of the pellets produced. Common materials are:

Carbon Steelmaterial: strong and durable, moderately priced, suitable for general feed processing.

Stainless steel material: strong corrosion resistance, good hygienic performance, suitable for processing materials with high water content and strong corrosiveness, such as fish meal, bone meal, etc.

2. Pellet diameter

Pellet diameter has an important impact on animal digestion and absorption, feed utilization rate and breeding methods. Common particle diameters are:

3mm: Suitable for young animals, sick and weak animals and animals for special feeding purposes.

5mm: Suitable for piglets, growing pigs, poultry, etc.

6mm: Suitable for growing and fattening pigs, beef cattle, mutton sheep, etc.

8mm: Mainly

used for large ruminants such as adult cattle and sheep.

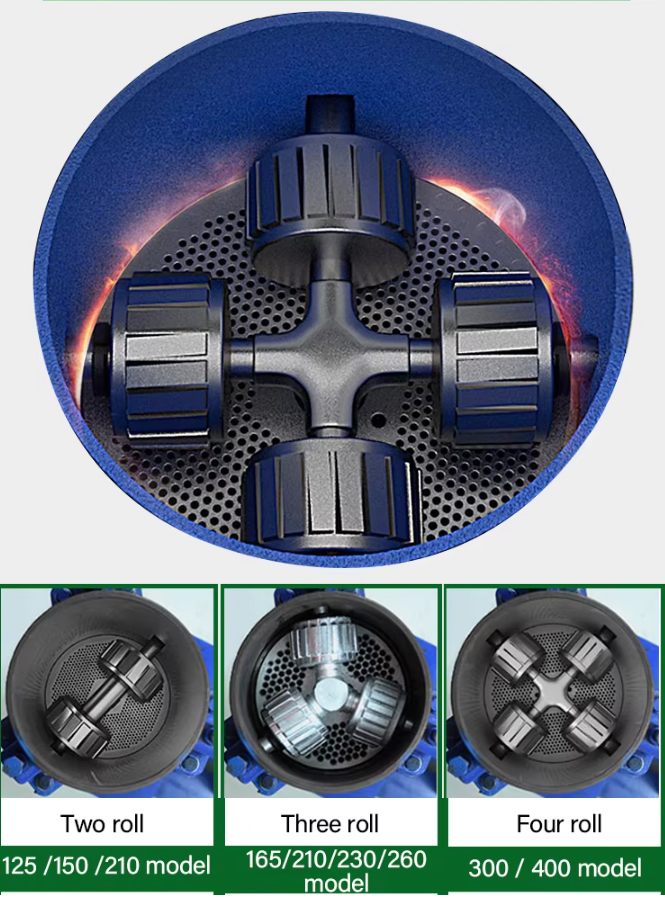

3.Roller

Generally speaking, the more rollers there are, the better the quality of the pellets, but the complexity and cost of the equipment will also increase accordingly.

Double roller: It is used to process materials with lower hardness, such as grains, soybean meal, etc., with relatively low production capacity, and is not suitable for processing materials with higher hardness.

Three rollers: It is suitable for processing materials with medium hardness and moderate moisture content, such as straw, sawdust, etc., and has higher production efficiency than the double roller machine.

Four rollers: It is suitable for processing materials with high hardness and high fiber content, such as straw, sawdust, etc., with high particle density, high strength, excellent wear resistance, and can produce high-quality pellets.

The particle diameter of the feed pellet machine has an important impact on animal digestion and absorption, feed utilization, and breeding methods. Pellets of different diameters are suitable for different types of animals and breeding methods.

8mm particles: mainly used for large ruminants such as adult cattle and sheep, with high energy density, which can reduce feed intake and reduce feeding costs.

6mm particles: suitable for growing and fattening pigs, beef cattle, mutton sheep, etc., with moderate particle size, which can not only meet the growth needs of animals, but also improve feed utilization.

5mm particles: suitable for piglets, growing pigs, poultry, etc., with small particles, easy for animals to eat and digest, suitable for young animals with imperfect digestive system development.

3mm particles: mainly used for young animals, sick and weak animals, and animals for special feeding purposes.

Features: The particles are extremely fine and easy to digest and absorb.

The feed pellet machine has certain requirements for the humidity of the material. The humidity of the material directly affects the molding effect and quality of the pellets.

1. Suitable humidity range

General requirements: The humidity of the material should usually be controlled between 12%-20%.

Too low: When the humidity is lower than 12%, the material is too dry and difficult to form, and the pellets are easy to loose.

Too high: When the humidity is higher than 20%, the material is too moist and easy to clog the mold, and the pellets are difficult to form and easy to mold.

2. Humidity requirements for different raw materials

Cereals: such as corn, wheat, etc., the humidity should be controlled at 12%-15%.

Proteins: such as soybean meal, fish meal, etc., the humidity should be controlled at 14%-18%.

Fibers: such as grass meal, straw, etc., the humidity should be controlled at 16%-20%.

3. The effect of humidity on pellet forming.

Molding effect: Appropriate humidity helps the material to better bond during the pressing process to form solid pellets.

Pellet hardness: Too low humidity will lead to insufficient pellet hardness and easy to break; too high humidity will make the pellet too hard, affecting animal digestion and absorption.

Production efficiency: Appropriate humidity can improve production efficiency and reduce equipment blockage and failure.

Small Feed Pellet Plant

Small feed pellet plant is mainly a single feed pellet machine, or equipped with feed pellet machine, screw conveyor, which is a small complete animal feed pellet plant, suitable for home and commercial use. If you are planning to start an animal feed pellet manufacturing business, this is a best choice because it requires low investment cost, occupies a small space, and has all the features of animal feed pellet production.

Feed Pellet Mill - Large Scale

Large-scale feed pellet plants are equipped with mixers, screw conveyors, silos, and pellet machines. The reasonable combination and use of these equipment can efficiently complete the feed production process. The equipment configuration and use of large-scale feed pellet plants is a systematic project that needs to be reasonably planned according to specific production needs.

A certain breeding farm is located in a rural area and focuses on poultry breeding business. In order to increase feed utilization and improve feed quality, they decided to introduce a feed pellet machine. After in-depth understanding and comparison, they chose Xinxiang Dahan feed pellet machine and purchased a pellet machine suitable for poultry feed processing. By using feed pellet machines, farms have achieved significant benefits. The feed pellet machine processes the feed raw materials into granules, which improves the density and stability of the feed, making it easier for poultry to digest and absorb, and the feed utilization rate is significantly improved.

Xinxiang Dahan is a well-known feed pellet machine manufacturer headquartered in Xinxiang City, Henan Province, China. Xinxiang Dahan Factory is committed to the research and development, production and sales of feed processing equipment. It has advanced production technology and technical team and is famous for providing high-quality feed pellet machine equipment.

Xinxiang Dahan's feed pellet machines are available in a variety of models and specifications, suitable for different feed processing needs. At the same time, manufacturers also provide customized solutions, designing and adjusting equipment according to customers' specific requirements to meet the needs of different farms. The manufacturer focuses on product quality and after-sales service, and provides customers with reliable equipment and comprehensive technical support through strict quality control and a complete after-sales support system.

We are a professional manufacturer in the field of feed pellet machines. We have been deeply involved in the industry for many years and have rich production experience and advanced technology. In terms of price, we always adhere to the concept of providing customers with cost-effective products. By optimizing the production process and purchasing raw materials on a large scale, we can minimize costs. The price is generally $180.00 - $285.00, allowing you to buy a feed pellet machine with excellent performance at an affordable price. Whether you are a small-scale farmer or a large-scale breeding enterprise, you can find equipment that meets your budget here. We look forward to working with you to create a brilliant breeding industry!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.