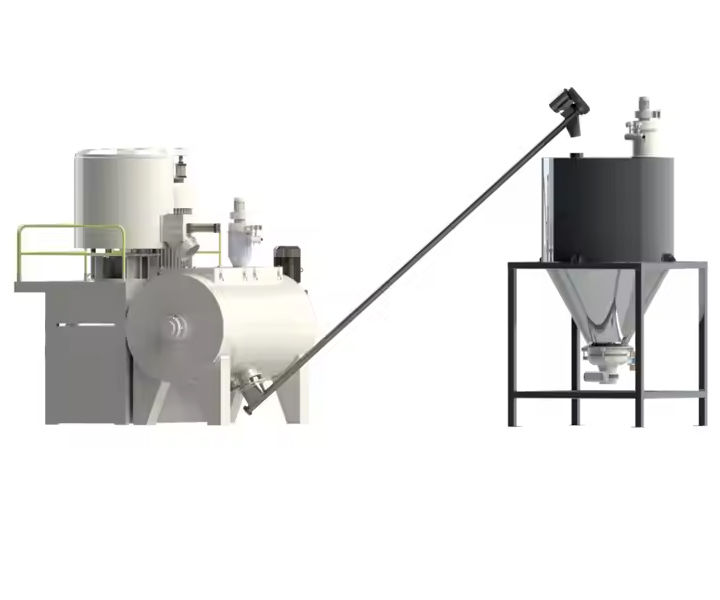

Widely used in mixing PVC resin with other materials in PVC extrusion, PVC granulation/particles and other industries.

![]()

![]()

Price:$2,500.00-$10,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-20min

Capacity: 100L-5000L

Weight: 100 kg-3000kg

Material: Stainless steel, Aluminum Alloy

Features: small size, light weight, high efficiency, low energy consumption, low noise

Application: used in mixing, stirring, drying, coloring and other techniques of plastics, rubber, chemicals for daily use.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Plastic high speed mixer is a special equipment used in the plastic industry for mixing, blending and compounding plastic materials. It is designed to quickly and thoroughly mix a variety of materials, including plastics, powders and liquids. They are widely used in the following industries: Plastics: Mixing PVC, PE, PP, ABS and other plastics for various applications.

As the core part of the compounding and masterbatch production process, Plastic high speed mixer is used for pre-mixing of all raw materials. Our mixers have a capacity from 5L to 2000L, with a mixing time of 0-30 minutes. There are high-speed mixers and hot and cold double-stage mixers.

Plastic high speed mixer is suitable for mixing, coloring and drying powdery and granular materials in plastic, rubber and chemical industries. It is typically used in the preparation of PVC dry blends, plastic filling and modification, preliminary mixing before extruder granulation, and multi-component mixing before wood plastic production. Here are some of its key functions:

1. Material Blending: It ensures that different components, such as plastics, additives, pigments, and fillers, are evenly distributed throughout the mixture.

2. Dispersion:Particle Dispersion: It breaks down larger particles into smaller, more uniform sizes.For materials that are not naturally miscible (e.g., oil and water), the mixer can create stable emulsions by dispersing one substance within the other.

3. Heat Generation: The high-speed rotation of the mixing blades generates heat through friction.This heat can accelerate chemical reactions, such as curing or polymerization, in certain applications.

4.Coloring: It ensures that pigments are evenly distributed throughout the material, resulting in a consistent color.

Thermoplastic High Speed Mixer

Thermoplastics soften when heated and harden when cooled, and can be heated and molded repeatedly. The main considerations when mixing are the melting temperature, viscosity and thermal stability of the materials.

Application: Suitable for mixing thermoplastics such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), ABS, etc.

Thermosetting Plastic High Speed Mixer

Thermosetting plastics crosslink and solidify when heated and cannot be melted again. When mixing, the main considerations are the reactivity, curing time and exothermic properties of the materials.

Application: Suitable for mixing thermosetting plastics such as phenolic resin, epoxy resin, unsaturated polyester resin, etc.

Engineering Plastic High Speed Mixer

Engineering plastics have excellent mechanical properties, heat resistance, chemical resistance, etc., and have high requirements for mixing equipment.

Application: Suitable for mixing engineering plastics such as polycarbonate (PC), polyamide (PA), polytetrafluoroethylene (PTFE), etc.

Filled Plastic High Speed Mixer

Filled plastic refers to adding a large amount of fillers such as calcium carbonate, talcum powder, etc. to plastics to reduce costs and improve performance.

Application: Suitable for mixing filled plastics such as filled polyethylene and filled polypropylene.

Plastic compounding: Mix various plastic raw materials, additives, pigments, etc. into plastic ingredients that meet the requirements.

Masterbatch production: Mix high-concentration pigments or other additives with carrier resins to make masterbatches for plastic coloring.

Recycled plastic processing: Recycle, clean, and crush waste plastics, and mix them with new materials to make recycled plastics.

Plastic modification: Improve the properties of plastics, such as heat resistance, wear resistance, toughness, etc., by adding various modifiers.

Plastic alloy preparation: Mix two or more plastics to make plastic alloys with excellent performance.

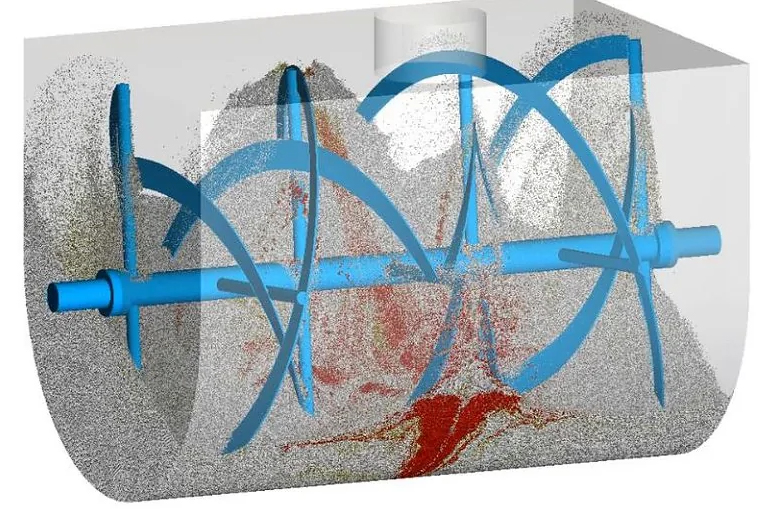

The high-speed mixer generates strong shear force and convection through the high-speed rotating stirring paddle, so that the plastic particles can be evenly mixed in a short time. Its core components include stirring paddle, mixing chamber, drive device and control system. When working, the materials are broken up, turned over and mixed by the high-speed stirring paddle in the mixing chamber to ensure that each part of the materials can be fully contacted.

Efficient mixing

Plastic high speed mixer can mix plastic raw materials quickly and thoroughly, greatly improving mixing efficiency and saving time and labor costs.

Uniformity

Through a high-speed rotating mixer or stirrer, the Plastic high speed mixer can evenly mix plastic raw materials of different particle sizes and types, ensuring the consistency and quality of the mixture.

Flexibility

The equipment can be adjusted and optimized for different plastic formulations and product requirements to meet the mixing requirements of different batches and production needs.

Energy saving

Plastic high speed mixers usually have high-efficiency energy consumption designs, reducing energy consumption and production costs.

Easy to operate

The equipment is simple to operate, easy to control and maintain, and operators can quickly get started and carry out effective production.

Improve product quality

By uniformly mixing and dispersing plastic raw materials, Plastic high speed mixer helps improve the physical properties, chemical stability and appearance quality of plastic products, ensuring that products meet high quality standards.

| Model | Volume(L) | Effective Volume(L) | Motor Power(kw) | Discharging Method | Heating Method |

| SHR-10 | 10 | 7 | 3 | Manual | Self Friction or Electric Heating |

| SHR-50 | 50 | 35 | 7/11 | Manual | Self Friction or Electric Heating |

| SHR-100 | 100 | 70 | 11/22 | Pneumatic | Self Friction or Electric Heating |

| SHR-300 | 30 | 210 | 40/55 | Pneumatic | Self Friction or Electric Heating |

| SHR-500 | 500 | 350 | 55/75 | Pneumatic | Self Friction or Electric Heating |

| SHR-1000 | 1000 | 700 | 110/160 | Pneumatic | Self Friction or Electric Heating |

| SHR-1500 | 1500 | 1050 | 220 | Pneumatic | Self Friction or Electric Heating |

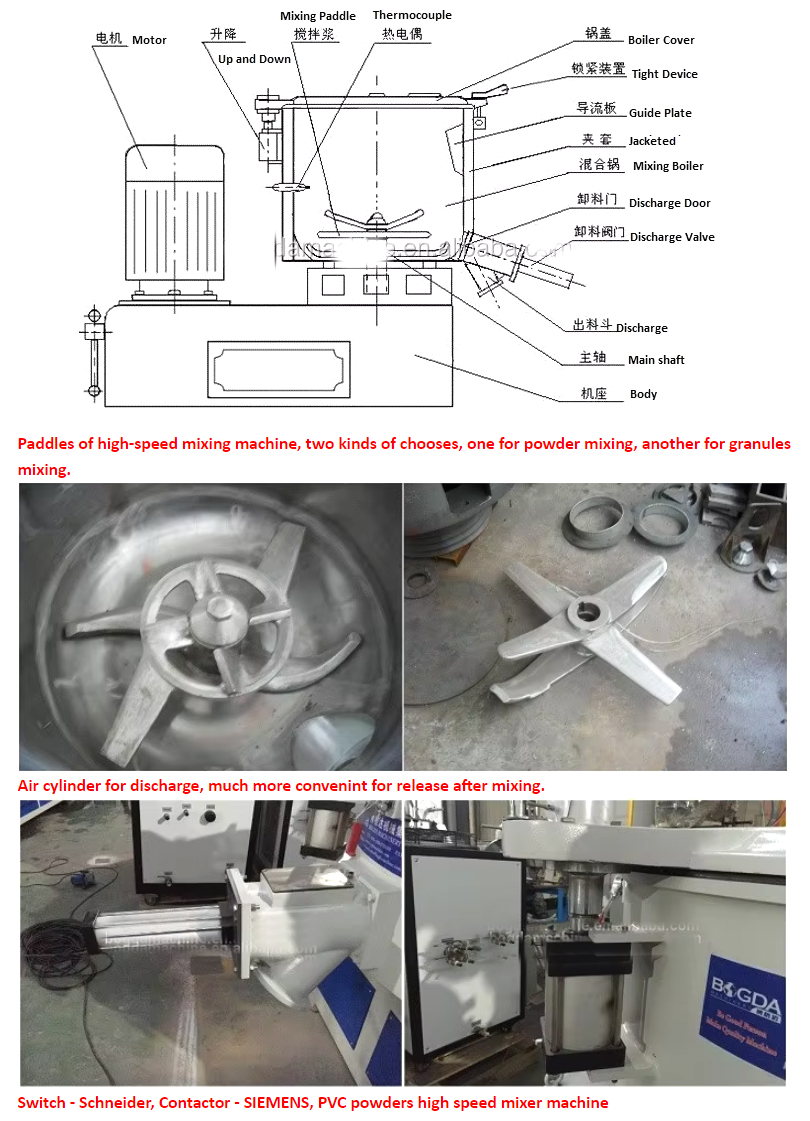

Mixing chamber: The mixing chamber is a space used to hold plastic raw materials and usually has a special design and structure to ensure effective mixing and dispersion effects.

Mixer or stirrer: The mixer or stirrer is the core component of the mixer, which stirs and mixes the plastic particles by rotating at high speed. Mixers or stirrers often have special shapes and blade designs to achieve efficient mixing and dispersion.

Transmission system: The transmission system is used to drive the rotational motion of the mixer or stirrer, and usually consists of a motor, a reducer and a transmission device.

Temperature control system: The temperature control system is used to control the temperature of the mixing chamber to adapt to the melting temperature and processing requirements of different plastic materials. It usually includes devices such as heaters and temperature sensors.

Control system: The control system is used to monitor and adjust various parameters and operations of the mixer, including mixing time, stirring speed, temperature control, etc., to achieve precise mixing control.

In the plastic processing industry, the mixing of PVC, PE, PP and ABS particles and powders is a key link. The following is a mixer selection recommendation and a detailed introduction to the mixing effect:

I. How to choose a mixer

Choose according to material characteristics

Granular materials: Granular materials have good fluidity, but require high mixing uniformity. It is recommended to choose a high-speed mixer or a double-helix cone mixer.

Powder materials: Powder materials are easy to fly and agglomerate. It is recommended to choose a ribbon mixer or a V-type mixer to ensure uniform mixing and reduce dust.

Select according to mixing requirements

High uniformity requirements: If extremely high mixing uniformity is required (such as masterbatch or functional masterbatch production), it is recommended to choose a high-speed mixer.

Mass production: For large-scale production, it is recommended to choose a twin-shaft paddle mixer or a large ribbon mixer to ensure efficient mixing.

Select according to process conditions

High temperature resistance requirements: If heating is required during the mixing process (such as PVC processing), choose a high-speed mixer with heating function.

Corrosion resistance requirements: If the material is corrosive, choose a mixer made of stainless steel.

2.Mixing effect analysis

PVC particles and powders: PVC particles and powders usually need to be mixed with additives such as plasticizers and stabilizers. High-speed mixers can achieve uniform mixing in a short time to ensure the stable performance of PVC products.

PE particles and powders: The mixing of PE particles and powders is mainly used for masterbatch or filler masterbatch production. Ribbon mixers or twin-shaft paddle mixers can ensure uniform distribution of colors and additives.

PP granules and powders: The mixing of PP granules and powders requires high uniformity. A three-dimensional motion mixer or high-speed mixer can achieve efficient mixing to ensure consistent product performance.

ABS granules and powders: ABS granules and powders usually need to be mixed with modifiers. A double-helix cone mixer or V-type mixer can ensure uniform distribution of the modifier and improve the mechanical properties of the ABS material.

Enhanced shear forces: High speeds create strong shearing forces that break down particles, improve mixing, and ensure uniform distribution.

Centrifugal force: High rotational speeds generate centrifugal force, which aids in dispersing materials and preventing segregation.

Turbulence: High-speed mixing creates turbulence, increasing the frequency of collisions between particles and promoting efficient mixing.

Faster reaction times: For processes involving chemical reactions, high speeds can accelerate the reaction rates.

Improved uniformity: High-speed mixing can lead to more consistent and homogeneous mixtures, ensuring better product quality.

In essence, high speeds in plastic high-speed mixers are essential for achieving efficient, thorough, and consistent mixing of various materials.

Plastic high speed mixer unit is mainly used for mixing and coloring PVC resin, coloring and drying of polyethylene and polypropylene particles, drying of hygroscopic resins such as ABS and polycarbonate before molding, mixing of phenolic resins, etc. Then, cooling is carried out by cooling and stirring to prevent agglomeration and degradation of hot mixed materials, so that additives in the hot mixed materials can continuously penetrate into the plastic resin, remove residual gas in the hot mixed materials, and store the hot mixed materials.

| NO | Model | unit | SRL-Z300/600 mixer |

| Hot mixer | |||

| 1 | Total volume of hot mixer | L | 300 |

| 2 | Effective volume of hot mixer | L | 225 |

| 3 | Material weight/batch | ㎏/batch | 120 |

| 4 | Output | ㎏/h | 540 |

| 5 | Motor power | KW | 55(Siemens) |

| 6 | Inverter | ABB | |

| 7 | Hot mixer rotating speed | r/min | 0-950 |

| 8 | Quantity of stirring blade | pcs | 3 |

| 9 | Blade structure | Three layer superposition with balancing test | |

| 10 | Mixing timee | min/batch | 8-10 |

| 11 | Inside wall thickness | mm | 8 |

| 12 | Inside wall material | 304# stainless | |

| 13 | Barrel bottom thickness | mm | 10 |

| 14 | Barrel bottom material | 304# stainless | |

| 15 | Treatment of mixer wall | polished | |

| 16 | Structure of baffle plate | Triangular welding of barrel wall | |

| 17 | Temperature measurement method and contact position | Thermocouple / middle part of inner Layer of barrel wall | |

| 18 | Hot mix machine pot | Casting aluminum | |

| 19 | Bearings | NSK | |

| 20 | The way of lid sealing | Double channel high temperature resistant rubber seal | |

| Cooling mixer | |||

| 1 | Cooling mixer volume | L | 600 |

| 2 | Effective volume of cooling mixer | L | 380 |

| 3 | Motor power | KW | 11 |

| 4 | Material of cooling mixer blade | / | ZG1Cr18Ni9Ti |

| 5 | Stirring blade rotating speed | r/m | 100 |

| 6 | Inside wall thickness | mm | 8 |

| 7 | Inside wall material | 304# stainless | |

| 8 | Lift control method | / | Pneumatici |

| 9 | Cooling method | / | Water cooling |

| 10 | Cooling time | min/batch | 10-12 |

| 11 | Overall size | mm | 4800(L)×2640(H)×2480(W) |

| Electrics | |||

| 1 | AC contactor | / | Schneider |

| 2 | Temperature controller | / | Omron or RKC |

A plastic products manufacturing company uses a plastic high speed mixer on its production line to improve product quality and production efficiency. The company manufactures a variety of plastic products, including plastic sheets and plastic containers. By using plastic high speed mixers, they are able to mix plastic raw materials of different types and particle sizes together quickly and evenly, ensuring product consistency and quality. In addition, the high efficiency of the plastic high speed mixer also helped them save a lot of time and labor costs.

Xinxiang Dahan plastic high speed mixer manufacturer has the following advantages: First of all, it has rich experience and professional knowledge. It has been committed to the R&D and manufacturing of plastic high speed mixer for many years and has strong technical strength. Secondly, advanced production technology and high-quality materials are used to ensure product reliability and durability. In addition, Xinxiang plastic high speed mixer manufacturers focus on innovation and constantly introduce advanced technology and equipment to improve product performance and efficiency. Finally, the company adheres to the principle of customer first and provides a full range of pre-sales and after-sales services to ensure customer satisfaction.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.