Horizontal ribbon mixer is a commonly used refractory material mixing equipment with the characteristics of efficient and uniform mixing. The working principle of the horizontal ribbon mixer will be introduced in detail below.

Horizontal ribbon mixer consists of a horizontal tank, spiral mixing blades, transmission device and motor. The tank body is usually made of stainless steel or carbon steel and has a certain volume and internal space.

Starting state: Before starting operation, put the refractory powder and other additives to be mixed into the tank of the horizontal ribbon mixer.

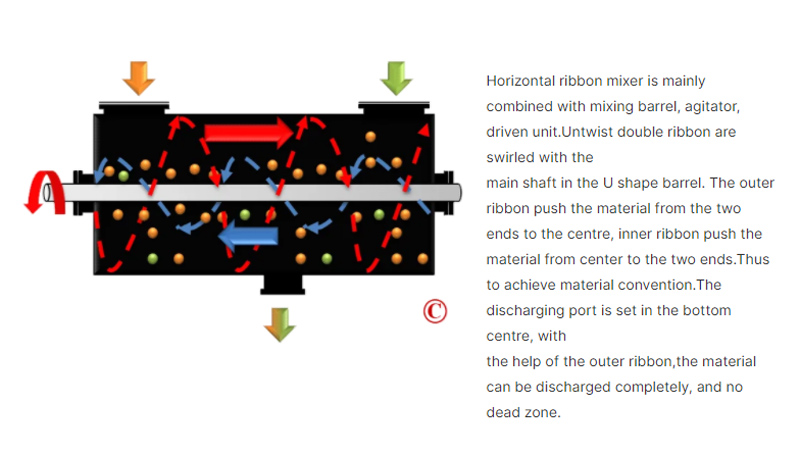

Mixing blade rotation: Start the motor and drive the mixing blade to rotate through the transmission device. The mixing blades are usually spiral-shaped and fixed on the main shaft. When the motor rotates, the mixing blades also rotate.

Mixing process: As the mixing blade rotates, the refractory powder begins to tumble, collide and mix inside the tank. The spiral shape and rotation direction of the mixing blade enable the material to form a continuous up and down circulation movement inside the tank.

Material flow: The shear force and centrifugal force generated by the rotation of the mixing blade push the material to flow inside the tank. The material slides down from the top of the mixing blade, and then is pushed up again by the mixing blade along the bottom of the tank, forming a circular flow.

Tumbling and collision: Materials are constantly tumbling, colliding and mixed during the circulation flow process. This tumbling and collision motion brings different particles of refractory powder into contact with each other to achieve a mixing effect.

Uniform mixing: The continuous tumbling, collision and mixing process gradually achieves uniform mixing of the refractory powder. Mixing time can be adjusted based on specific mixing requirements.

Complete mixing: When the desired mixing level is reached, stop the motor. Open the discharge port of the mixer and take out the mixed refractory material mixture.

The working principle of the horizontal ribbon mixer is based on the rotation and spiral shape of the mixing blades. Through the tumbling, collision and circular flow of materials, the uniform mixing of refractory powder is achieved. This working principle enables the horizontal ribbon mixer to have efficient and uniform mixing effects, and is suitable for the mixing process in refractory materials, chemical industry, metallurgy, building materials and other industries. At the same time, the horizontal ribbon mixer is easy to operate, easy to maintain and clean, and improves production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.