Silica powder liquid mixing site price is usually affected by multiple factors, including region, market supply and demand, mixing equipment scale and quality requirements, etc. The following are some factors that may affect the price. It should be noted that the information provided below is for reference only and the actual price may vary depending on the specific situation. In order to obtain accurate price information, it is recommended that you contact the local silicon fume liquid mixing site directly to consult their price policy and specific quotation. They will be able to give more accurate prices and detailed descriptions of fees.

There may be differences in demand and price levels for silica fume liquid mixing services in different regions and markets. Generally speaking, in developed areas and places with large market demand, prices may be relatively high.

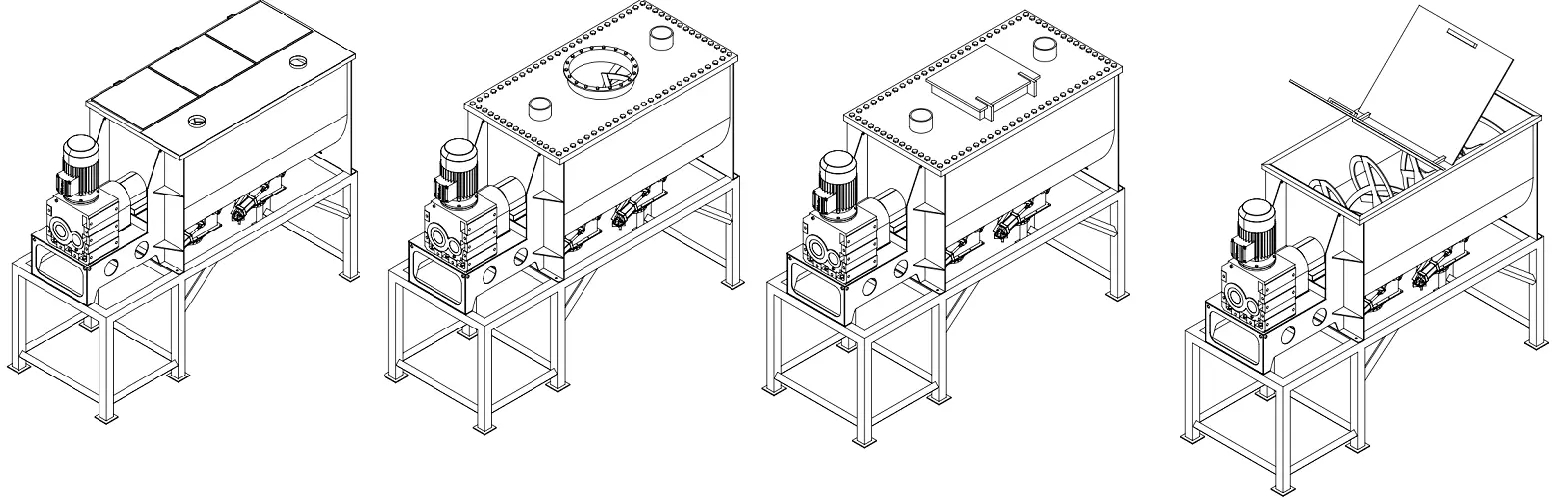

The size and quality of the mixing equipment will affect the price. Larger equipment typically has higher production capabilities, but also costs more. At the same time, if customers have higher quality requirements, they may need to use more sophisticated equipment and processes, thus increasing costs and prices.

The price of silicon fume liquid will vary depending on market supply and demand and raw material quality. Mixing sites usually take the cost of raw materials into account and factor this into the final price.

The mixing site may calculate fees based on mixing time and workload, because this directly affects the use of equipment and human resources. Longer mixing times and extensive work may increase the price.

If the mixing site provides transportation services for the silica fume liquid, transportation costs may be included in the overall price. Shipping costs typically vary based on factors such as distance, traffic conditions, and mode of transportation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.