PVC plastic high speed mixer is a device that mixes PVC resin and other additives through a high-speed rotating agitator. It adopts an efficient mixing principle, which can quickly and evenly mix plastics of different components together to form a uniform PVC mixture. This kind of mixer usually consists of a frame, motor, agitator, hopper and control system. PVC plastic high-speed mixer plays an important role in the plastic processing industry.

PVC plastic high speed mixer uses a high-speed rotating mixer to mix PVC resin and other additives through the high-speed rotation of the mixer and the design of the mixing blades. During the mixing process, the mixer produces strong cutting, shearing and squeezing effects to fully mix the PVC resin and additives and form a uniform PVC mixture.

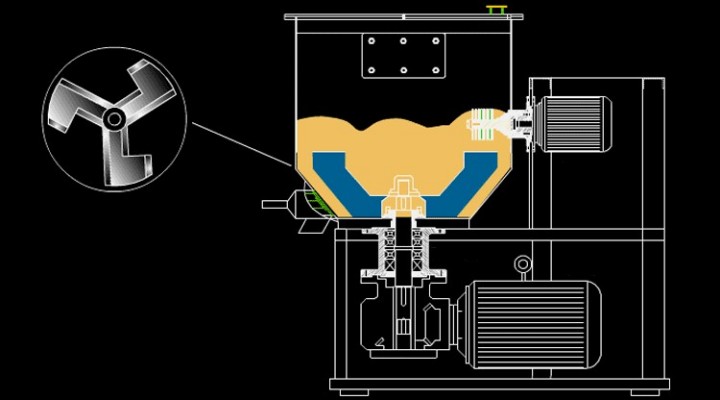

PVC plastic high speed mixer consists of the following main components:

Rack: Provides support and stability for equipment.

Motor: drives the mixer to rotate at high speed.

Mixer: Includes mixing blades and mixing chamber, which mixes resin and additives by rotating.

Hopper: used to load PVC resin and other additives.

Control system: used to control the start, stop and operating parameters of the equipment.

| Model | Volume(L) | Effective Volume(L) | Motor Power(kw) | Discharging Method | Heating Method |

| SHR-10 | 10 | 7 | 3 | Manual | Self Friction or Electric Heating |

| SHR-50 | 50 | 35 | 7/11 | Manual | Self Friction or Electric Heating |

| SHR-100 | 100 | 70 | 11/22 | Pneumatic | Self Friction or Electric Heating |

| SHR-300 | 30 | 210 | 40/55 | Pneumatic | Self Friction or Electric Heating |

| SHR-500 | 500 | 350 | 55/75 | Pneumatic | Self Friction or Electric Heating |

| SHR-1000 | 1000 | 700 | 110/160 | Pneumatic | Self Friction or Electric Heating |

| SHR-1500 | 1500 | 1050 | 220 | Pneumatic | Self Friction or Electric Heating |

PVC plastic high speed mixer is widely used in the plastic processing industry, especially in the production process of PVC products. It is suitable for the following customer application scenarios:

PVC product production: such as the preparation process of PVC pipes, PVC sheets, PVC profiles, etc.

PVC composite material production: The process of mixing PVC resin with other materials (such as wood powder, fiber, filler, etc.) to prepare PVC composite materials.

PVC granule preparation: Mix PVC resin with additives to form a uniform PVC mixture, providing high-quality raw materials for subsequent melt extrusion.

The main function of the PVC plastic high speed mixer is to uniformly mix PVC resin and other additives to ensure the uniform distribution of various components in the PVC mixture. It has the following functions:

Improve mixing efficiency: Through the action of the high-speed rotating agitator, plastics with different components can be quickly and evenly mixed together.

Improve product quality: through uniform mixing, ensure the uniform distribution of various ingredients in the PVC mixture, thereby improving the physical properties and appearance quality of the final product.

Improve production efficiency: plastic high speed mixer can efficiently complete the mixing process, improve production efficiency, and reduce production costs.

Efficient mixing: Through high-speed stirring, PVC resin and additives can be quickly and evenly mixed together to improve mixing efficiency.

Uniform distribution: The design and rotation of the agitator can ensure the uniform distribution of various ingredients in the PVC mixture and improve product quality.

Easy operation: The equipment has a simple structure, is easy to operate, and is easy to control and maintain.

Energy saving: The efficient mixing process of plastic high speed mixer can save energy and reduce production costs.

There are many types of PVC plastics. The physical and chemical properties, processing performance and requirements for mixed materials of different types of PVC plastics are different, so when choosing a mixer, you need to choose according to the specific situation.

Hard PVC (UPVC): High hardness, high strength, good weather resistance, but narrow processing temperature range and poor thermal stability. It is recommended to choose a high-speed hot mixer + low-speed cold mixer. The high-speed hot mixer can quickly heat the material to the plasticizing temperature, shorten the mixing time and reduce thermal decomposition. The low-speed cold mixer can effectively cool the mixture to prevent agglomeration and improve fluidity.

Soft PVC (SPVC): Soft, elastic, easy to process, but high in plasticizer content and relatively good thermal stability. You can choose a high-speed hot mixer, which can quickly mix the plasticizer with PVC resin and improve mixing efficiency.

Chlorinated PVC (CPVC): Excellent heat resistance, corrosion resistance, and flame retardancy, but difficult to process and high melt viscosity. You can choose a high-speed hot mixer + a low-speed cold mixer. The high-speed hot mixer can provide stronger shear force to promote the plasticization of CPVC resin, and the low-speed cold mixer can effectively reduce the temperature of the mixture to prevent agglomeration.

PVC Paste Resin: Fine particles, easy to form a paste, used in the production of artificial leather, wallpaper, etc. You can choose a mixer with good sealing to prevent paste leakage.

Dahan Machinery is a professional PVC plastic high-speed mixer manufacturer integrating R&D, production, sales and service. We have many years of industry experience and technical accumulation, and are committed to providing customers with efficient, stable and durable mixing equipment to help PVC plastic products companies improve production efficiency and product quality.

Our advantages

Advanced technology: Using advanced mixing technology and manufacturing processes to ensure excellent equipment performance, high mixing uniformity and good plasticization effect.

High-quality materials: Key components are made of high-quality alloy steel and wear-resistant materials, which are durable and have a long service life.

Customized service: Provide customized services according to customer needs to meet the special requirements of different materials and processes.

Perfect after-sales: Provide perfect after-sales service, including equipment installation and commissioning, operation training, repair and maintenance, etc., to ensure that customers have no worries.

Our customers:

Our products are widely used in PVC pipes, profiles, plates, films, cable materials and other fields, and are deeply trusted and praised by domestic and foreign customers.

If you are looking for a reliable PVC plastic high-speed mixer supplier, please feel free to contact us. We will wholeheartedly provide you with quality products and services!

PVC plastic high speed mixer uniformly mixes PVC resin and other additives through a high-speed rotating mixer to improve the quality and consistency of PVC mixtures. It is widely used in the fields of PVC product production, PVC composite material preparation and PVC granule preparation. Its advantages include efficient mixing, uniform distribution, ease of operation and energy savings. With the continuous development of plastic processing technology, PVC plastic high speed mixer machines will continue to play an important role in promoting the development and innovation of the plastic industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.