SRL-Z plastic high speed mixer is a piece of equipment used in the plastics processing industry. It is designed to quickly and uniformly mix plastic particles, powders and additives to achieve rapid and uniform mixing of plastic raw materials. It includes a host machine, a mixing mechanism and other parts. The mixing blade rotates at high speed to effectively mix the raw materials. The main machine is made of high quality steel with a sturdy and durable structure, suitable for long-term and high-intensity working environments. SRL-Z plastic high speed mixer features stable operation, simple operation and durability. It is widely used in the production process of plastic products to improve production efficiency and product quality.

In the SRL-Z plastic high speed mixer the key component is the mixing mechanism, which consists of a high speed rotating mixing blade. These blades are reasonably designed and scientifically laid out, and can effectively and quickly mix plastic particles, powders and additives to ensure a uniform mixing effect. At the same time, the SRL-Z mixer is also equipped with a cooling water circulation system, which can effectively control the temperature during the mixing process and prevent the raw materials from overheating due to friction.

SRL-Z plastic high-speed mixer is widely used in the field of plastic product production, including injection molding, extrusion, blow molding and other process links. During plastic processing, the SRL-Z mixer can quickly and evenly mix various plastic raw materials, such as polyethylene, polypropylene, polyvinyl chloride and other resins, as well as color masterbatch, filler and other additives. Through the high speed stirring effect of the SRL-Z mixer, the raw materials can be fully mixed, improve production efficiency, reduce production costs, and ensure stable product quality. This kind of equipment plays a key role in the production of plastic products, helping plastic processing companies improve production levels and meet market demand.

PVC product production: used to mix PVC resin and additives, and produce PVC pipes, plates, profiles and other products.

Plastic processing plant: used to mix various plastic raw materials, such as PE, PP, etc., to prepare plastic products.

PE, PP pipe, sheet, film and other production lines: used for mixing PE, PP resin particles or powder with masterbatches, additives, etc.

Cable material, masterbatch, modified plastics, etc. production: used for uniform mixing of various plastic raw materials and additives, providing high-quality raw materials for subsequent granulation or extrusion.

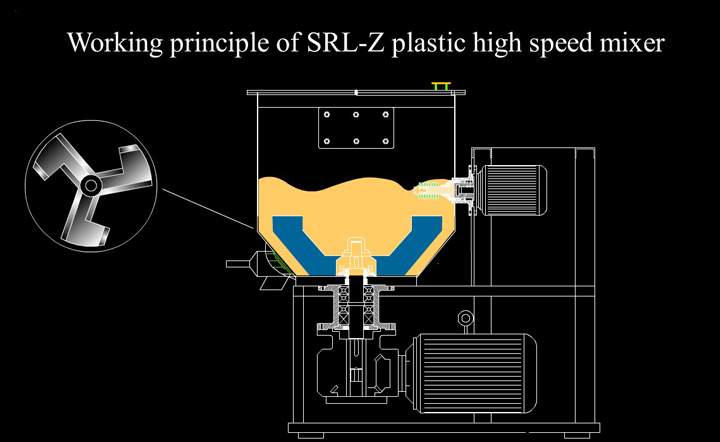

The working principle of the SRL-Z plastic high speed mixer is to drive the mixing mechanism through the host machine, causing the mixing blade to rotate at high speed, and place the mixture of plastic raw materials, color masterbatch and additives in the container to achieve rapid and uniform mixing. The high speed rotation of the mixing blade generates strong stirring and shearing forces, allowing the raw materials to be thoroughly mixed in a short time to ensure even distribution of various ingredients. The internal structure of the mixer is reasonably designed, which can effectively prevent the accumulation and adhesion of raw materials and ensure the mixing effect. This working principle makes the SRL-Z mixer an efficient and reliable mixing equipment in the plastic processing industry.

Efficient mixing: The mixing blade rotates at high speed to quickly mix raw materials, saving time and cost.

Uniform mixing: It can ensure the uniform distribution of various raw materials and additives and improve product quality.

Stable operation: reasonable structural design, simple operation, high stability, and reduced failure rate.

Strong durability: Made of high-quality materials, wear-resistant and corrosion-resistant, with long service life.

Versatility: Suitable for mixing various plastic raw materials, widely used in the production of plastic products to improve production efficiency and product quality.

In the plastic processing process, choosing a suitable mixer is crucial to ensuring product quality and production efficiency. Plastics and granular powder additives of different materials have different physical and chemical properties, so they need to be selected according to specific circumstances.

Thermoplastics (such as PVC, PE, PP, ABS, etc.): Recommended type SRL-Z series high-speed mixer, because the high-speed rotating stirring paddle and specially designed mixing chamber structure can ensure that the material reaches a highly uniform mixing state in a short time

Thermosetting plastics (such as phenolic resin, epoxy resin, etc.): Recommended double planetary mixer, which can provide strong shear force and kneading force to fully mix the thermosetting resin and curing agent to ensure uniform curing reaction.

Elastomers (such as rubber, silicone, etc.): Recommended: Internal mixer, which can provide strong shear force and high temperature and high pressure environment to fully mix the elastomer and compounding agent to improve the mixing effect. Suitable for mixing high viscosity and high elastic materials.

Inorganic fillers (such as calcium carbonate, talcum powder, glass fiber, etc.): Recommended high-speed mixer + low-speed cold mixer, high-speed mixer can quickly mix inorganic fillers and resins evenly and shorten the mixing time. Low-speed cold mixer can effectively reduce the temperature of the mixture, prevent agglomeration, and improve fluidity.

Organic additives (such as plasticizers, lubricants, antioxidants, etc.)

A high-speed mixer is recommended to quickly mix organic additives with resin and improve mixing efficiency.

| Model | Volume(L) | Effective Volume(L) | Motor Power(kw) | Discharging Method | Heating Method |

| SHR-10 | 10 | 7 | 3 | Manual | Self Friction or Electric Heating |

| SHR-50 | 50 | 35 | 7/11 | Manual | Self Friction or Electric Heating |

| SHR-100 | 100 | 70 | 11/22 | Pneumatic | Self Friction or Electric Heating |

| SHR-300 | 30 | 210 | 40/55 | Pneumatic | Self Friction or Electric Heating |

| SHR-500 | 500 | 350 | 55/75 | Pneumatic | Self Friction or Electric Heating |

| SHR-1000 | 1000 | 700 | 110/160 | Pneumatic | Self Friction or Electric Heating |

| SHR-1500 | 1500 | 1050 | 220 | Pneumatic | Self Friction or Electric Heating |

SRL-Z series plastic high-speed mixer is usually composed of the following main components

Hot mixing barrel: Made of high-quality stainless steel, it has good corrosion resistance and wear resistance. The inside of the barrel is precisely polished to reduce material adhesion and facilitate cleaning.

Stirring spindle: Made of high-strength alloy steel, it is precisely processed and dynamically balanced to ensure stability and low noise during high-speed rotation.

Stirring blade: According to different mixing requirements and material characteristics, it is designed with different shapes and installation angles. Common blade types include:

Twisted blade: Produces strong axial and radial flow, suitable for mixing powders and particles.

Wall scraping blade: Rotates close to the barrel wall, scrapes off the material adhering to the wall, and enhances the mixing effect and heat transfer efficiency.

Sealing device: Installed at the position where the stirring spindle passes through the barrel, it is used to prevent material and dust leakage and ensure the cleanliness and safety of the mixing process.

Exhaust device: Used to discharge gas or steam generated during the mixing process.

Feed port: used to put materials into the hot mixing drum, usually with a sealing cover.

Discharge port: usually located at the bottom of the drum, equipped with a pneumatic or manual valve, used to quickly transport the mixed hot materials to the cold mixing drum.

SRL-Z plastic high-speed mixer is a kind of equipment specially used in plastic processing industry, and its methods include:

Dry mixing: Put plastic particles and other raw materials such as additives into the mixer, and mix them evenly through the high-speed rotating agitator.

Heating mixing: During the mixing process, the plastic raw materials can be heated by the heating system to promote the melting and mixing of the plastic.

Cooling mixing: After the mixing is completed, the mixed plastic can be cooled by the cooling system to solidify it into the desired shape.

SRL-Z plastic high-speed mixer plays a vital role in modern plastic processing, and its importance is reflected in the following aspects.

Ensure product quality: It can ensure that various components are fully dispersed and mixed, avoiding product performance degradation or appearance defects caused by uneven mixing.

Improve production efficiency: High-speed mixing and rapid temperature rise and fall process greatly shorten the material preparation time and improve the overall production efficiency.

Optimize production process: Precise temperature and time control can optimize the mixing process, improve the plasticization effect of the material, and create more favorable conditions for subsequent extrusion, injection molding and other processes.

Reduce production costs: High-speed mixing and automated operation can reduce energy consumption and labor costs, thereby reducing overall production costs.

In general, the SRL-Z plastic high speed mixer, as one of the important equipment in the plastic processing industry, has the characteristics of high efficiency, stability and reliability, and provides important support for the production of plastic products. When selecting and using the SRL-Z mixer, it is necessary to perform reasonable configuration and operation according to production needs and raw material characteristics to ensure the best mixing effect and production efficiency. Through the rational use of SRL-Z plastic high speed mixer, the overall level of plastic product production can be improved, meet market demand, and promote the development and progress of the industry.

Dahan Machinery has many years of industry experience and technical accumulation, and is committed to providing customers with efficient, stable and durable mixing equipment. The use of advanced mixing technology and manufacturing processes ensures excellent equipment performance, high mixing uniformity and good plasticizing effect. The key components are made of high-quality alloy steel and wear-resistant materials, which are durable and have a long service life. Each device undergoes strict quality inspection before leaving the factory to ensure stable and reliable performance. Provide complete after-sales service, including equipment installation and commissioning, operation training, repair and maintenance, etc., to ensure that customers have no worries. The capacity ranges from 10L to 1000L to meet the production needs of different customers. Customized services can be provided according to customer needs to meet the requirements of special materials and processes. The price will also change with the model. If you are looking for a cost-effective SRL-Z plastic high-speed mixer, please feel free to contact us. We will send you a detailed price list based on your situation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.