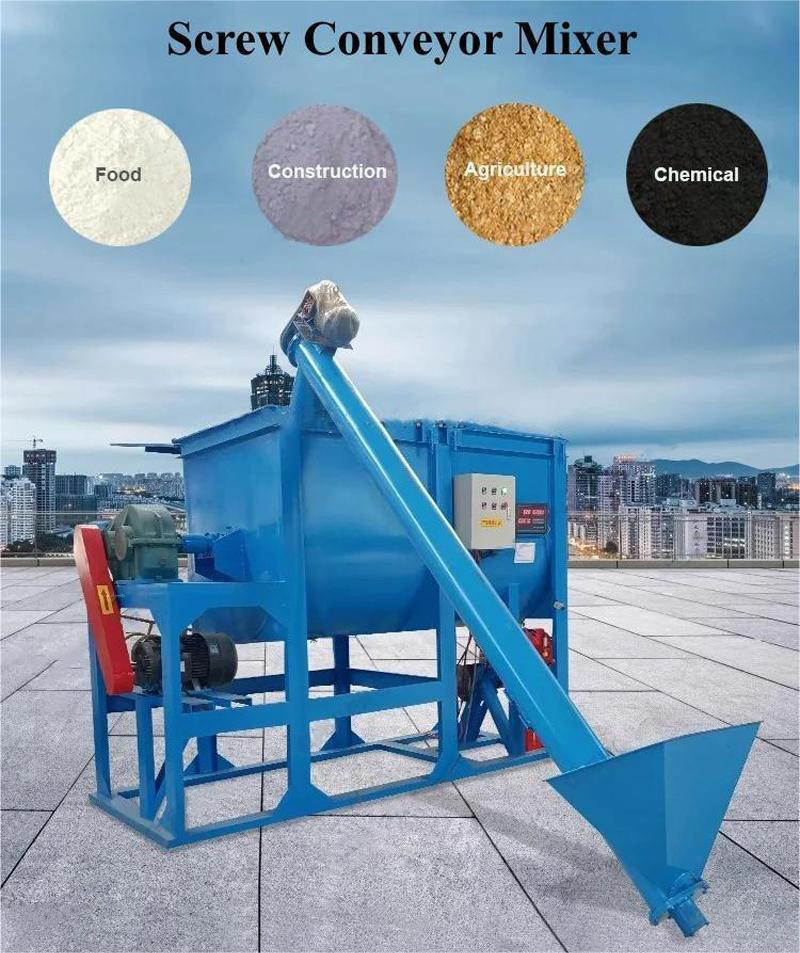

An efficient device that uniformly mixes materials with different components through spiral rotation and conveying.

![]()

![]()

Price:$1000.00-$8,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 100-6000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Mixing time: 8-20min

Mixing speed: 15-60r/min

Frequency: 50HZ、60HZ

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Chemical, pharmaceutical, food, metallurgy, building materials, environmental protection and other industries, used for mixing dry powder and granular materials

Screw Conveyor Mixer is an industrial mixing equipment, mainly used to uniformly mix materials with different components. It uses a spiral rotation and conveying method to push and turn materials along the spiral axis to achieve mixing of materials. A screw conveyor mixer usually consists of a screw shaft, a screw blade, a silo and a transmission device. When the spiral shaft rotates, the spiral blades transport the material from the bottom to the top of the silo, and at the same time push and turn the material forward to evenly mix materials with different components.

Screw conveyor mixers are widely used in industrial production. It can be used in chemical, pharmaceutical, food, metallurgy, building materials and other industries to mix dry powder and granular materials. Through the rotation and transportation of the screw, the screw conveyor mixer can mix materials quickly and evenly, improving production efficiency and product quality. It can not only mix materials, but also realize the conveying and unloading functions of materials, providing an efficient and reliable mixing solution for industrial production.

Screw conveyor mixers can be divided into two types: vertical and horizontal.

Vertical screw conveyor mixer: The main feature of the vertical screw conveyor mixer is that the screw shaft is installed vertically and the mixing chamber is usually cylindrical. During the mixing process of this type of mixer, the material is pushed by the spiral blades, moves upward from the bottom, and then falls back from the top to form a cyclic mixing. Vertical screw conveyor mixers are suitable for larger-capacity mixing requirements and are widely used in chemical, pharmaceutical, building materials and other industries.

Horizontal screw conveyor mixer:The main feature of the horizontal screw conveyor mixer is that the screw shaft is installed horizontally, and the mixing chamber is usually rectangular or cylindrical. During the mixing process, the materials are transported and mixed along the length of the mixing chamber by the propeller blades. Horizontal screw conveyor mixers are suitable for smaller capacity mixing requirements and are commonly used in food processing, cosmetics, pesticides and other industries.

Screw conveyor mixers have a wide range of applications and are mainly used in the following areas:

Chemical industry: In chemical production, screw conveyor mixers can be used to mix different chemical materials, such as powders, granular solid materials, liquid materials, etc. It can achieve rapid and uniform mixing of materials with different components and meet the mixing process requirements in chemical production.

Pharmaceutical industry: In pharmaceutical production, screw conveyor mixers are often used to mix pharmaceutical raw materials such as pharmaceutical powders, tablets, and capsules. It can ensure the uniform mixing of pharmaceutical raw materials and improve the quality and stability of pharmaceuticals.

Food industry: In food processing, screw conveyor mixers can be used to mix powdered food raw materials, such as flour, condiments, additives, etc. It can evenly mix food raw materials with different ingredients to ensure the taste and quality of food.

Metallurgical industry:In metallurgical production, screw conveyor mixers are often used to mix metal powder, ore powder and other materials for subsequent smelting or processing.

Building materials industry: In building materials production, screw conveyor mixers can be used to mix cement, gypsum, mortar and other materials to make mortar, concrete and other building materials.

The working principle of the screw conveyor mixer is as follows:

Material feeding:First, add the materials to be mixed into the silo of the screw conveyor mixer through the feeding port.

Screw rotation: Start the transmission device of the screw conveyor mixer to make the screw shaft start to rotate. The screw shaft is usually located in the center of the silo and extends to the bottom of the silo.

Material transportation: As the screw shaft rotates, the spiral blades are fixed on the screw shaft to transport the material upward from the bottom of the silo. The design of the spiral blades causes the materials to turn and mix during the conveying process.

Mixing process: When materials are pushed to the top of the silo, they will slide down along the silo wall, and then be pushed to the bottom of the silo again by the spiral blades. This process is repeated continuously, causing the materials to be continuously turned, pushed and mixed in the screw conveyor mixer.

Mixing completed:Through continuous screw conveying and turning, materials with different components are evenly mixed in the screw conveyor mixer. Finally, the mixed materials can be discharged through the discharge port.

Uniform mixing

The screw conveyor mixer can achieve rapid and uniform mixing of materials through the promotion of spiral blades and the continuous turning of materials. It can fully mix materials with different components to ensure stable quality of the mixed products.

Efficient and energy-saving

The screw conveyor mixer has efficient mixing effect and conveying capacity, and can complete the mixing process in a short time. At the same time, it has a simple structure, low power consumption and energy saving.

Easy operation

The operation of the screw conveyor mixer is relatively simple, you only need to start the transmission device to start working. At the same time, its maintenance is relatively easy, reducing the workload of operators.

Strong adaptability

The screw conveyor mixer is suitable for mixing a variety of materials, including powders, granular solid materials and liquid materials. It can be adjusted and customized according to different production needs to suit the mixing requirements of different industries.

Compact structure

Screw conveyor mixers usually adopt a vertical structure and occupy a relatively small area. This makes its layout and installation in the factory more convenient and saves space.

High reliability

The screw conveyor mixer adopts wear-resistant materials and reliable transmission devices, which has high durability and stability. It can operate stably for a long time, reduce failures and downtime, and improve production efficiency.

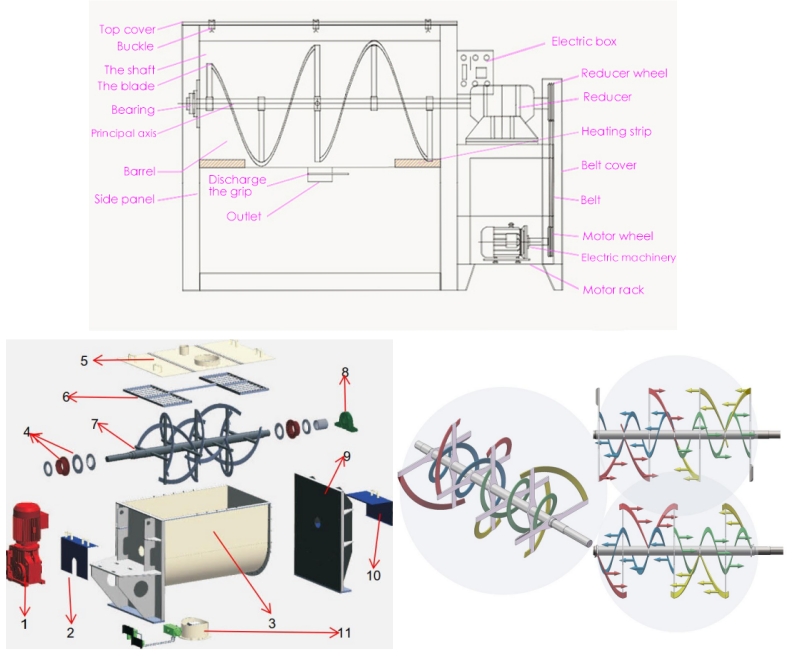

Feed inlet (hopper): The feed inlet is the entrance of the screw conveyor mixer, which is used to load the raw materials to be mixed into the mixer.

Screw conveyor: The screw conveyor is the core component of the screw conveyor mixer, usually composed of a screw blade and a screw shaft.

Mixing area: The mixing area is the area inside the screw conveyor mixer to achieve the mixing of raw materials.

Discharge port: The discharge port is located at the outlet of the screw conveyor mixer, which is used to discharge the mixed raw materials out of the machine.

Drive device: The drive device is usually composed of a motor, a reducer and a transmission device, which is used to drive the rotational movement of the screw conveyor.

Support structure: The support structure is used to support the overall frame of the screw conveyor mixer.

1. Model selection

Suppliers of screw conveyor mixers allocate their models by vessel volume capacity. Note that the volume of the container does not refer to the total weight of the product, but to get that value you must know the bulk density of the product and multiply it by the volume of the container. Consider the maximum and minimum batch sizes that a particular model can support. Optimal mixing in a mixer requires a certain amount of product, at least 30-40% of the nominal capacity. When handling smaller volumes, the mixer may not create sufficient contact between the mixer and the product. While the maximum volume is typically 60% to 75%, if this volume is exceeded, the mixing time may be much longer than specified and more power will be required.

2.Power transmission selection

Screw slat mixers that are directly driven by gear reducers are often recommended because they require less maintenance and perform better overall. Gear motors work well with electronic inverters, providing variable speed, overload protection and adjustable starting torque (soft start). Direct drive belt mixers eliminate problems such as belt slippage and stretch, excessive overhung loads, and noise from chain drives. However, the economic difference is large. The direct gear reducer has the highest cost, and the motor pulley belt drive is the most economical. However, in terms of the effectiveness and efficiency of transmitting power, the motor and direct gear reducer are better.

3.Discharge port selection

Product is discharged through an outlet located in the center of the "U" shaped trough or bottom of the tundish. Dust-proof knife gate valve (gate valve) is generally suitable for dry materials such as powder. Ideal choice for liquid butterfly valves for most vacuum/pressure requirements and wet applications. For sensitive products where there is a need to minimize "dead spots" in channels where product can accumulate, a ball valve or drain plug valve may be ideal. Also consider whether your mixer would benefit from a pneumatic valve to more precisely control the discharge process.

4.Add material method options

The procedure for adding components or raw materials, first load the main components into the container of the ribbon mixer, then add the dry secondary ingredients, which must be placed in the center or divided into equal portions and placed on both sides of the ribbon mixer side. Liquids, on the other hand, are usually added while the spiral belt agitator is running. The liquid should be sprayed in the center of the system, or if using multiple nozzles, an equal number of nozzles will need to be used on the left and right sides for best results.

5.Blender options

In addition to spiral belt rotors, other types of mixers are also available, such as interchangeable paddle mixers (for processing fragile materials) or high-speed mixers with chopping blades (for breaking up large chunks quickly). Standard models typically have a 60 or 80 grit finish on the interior surface, which is sufficient for many applications. Polishing with a 150 grit or higher grit helps further reduce material buildup and makes cleaning easier. In most cases, there is no need to remove the mixer for maintenance.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Mixer can be used in conjunction with a screw conveyor, a vibrating screen, a belt conveyor, and a packaging machine, each of which has its own unique function.

1. Mixer matches the screw conveyor:

It can achieve the mixing and conveying of raw materials. After the mixer mixes the raw materials, the mixed product is conveyed to the designated location by the screw conveyor.

2. Mixer matches the vibrating screen:

It can achieve the mixing and screening process of raw materials. After the mixer mixes the raw materials of different components evenly, it is screened through a vibrating screen to separate the particles or powders that meet the requirements.

3. Mixer matches the belt conveyor:

It can achieve the conveying and mixing of raw materials. After the mixer mixes the raw materials, the mixed product is conveyed to the next process by a belt conveyor.

4. Mixer matches the packaging machine:

It can achieve the mixing, packaging and encapsulation of products. After the mixer mixes the raw materials, it is automatically packaged by the packaging machine.

A chemical company has had significant success using screw conveyor mixers on its production lines. The company's products require blending of multiple powder ingredients to ensure product quality and consistency. Before the introduction of the screw conveyor mixer, the company used traditional manual mixing methods, which were inefficient and uneven, resulting in large fluctuations in product quality.

By introducing a screw conveyor mixer, the chemical company has automated and optimized the mixing process. The screw conveyor mixer uses its efficient mixing principle to quickly and evenly mix powder raw materials with different components. This not only improves mixing efficiency but also ensures product consistency and stability.

Xinxiang Dahan screw conveyor mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the screw conveyor mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The screw conveyor mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan Dry Powder Mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. is one of the trustworthy screw conveyor mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.