Dry mortar is a commonly used building material that can be used for masonry of walls, floors, ceilings and other structures, as well as repair and filling projects. The configure process of dry mortar needs to be carried out according to the specific construction requirements and mortar formula. The following are the preparation steps and precautions for dry mortar.

Determine the required mortar formula and construction requirements, including mortar type, proportion, use, etc.

Prepare the required raw materials, including cement, sand, filler, etc. Determine the amount of each raw material according to the recipe.

Use weighing equipment to accurately measure the amount of each raw material. Measure by weight or volume, depending on recipe proportions.

Pour the measured amounts of cement, sand and filler into the mixer.

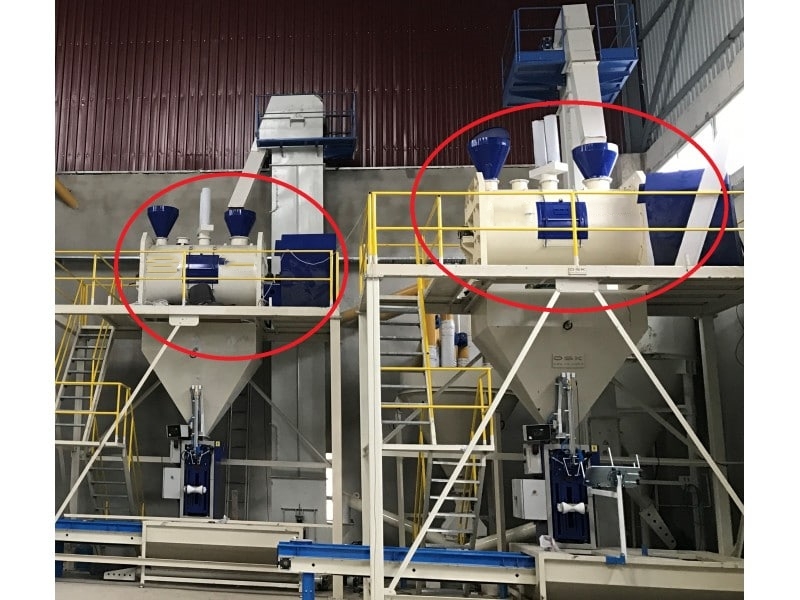

You can first use mortar dry powder mixer to mix the raw materials, which is more convenient and labor-saving, and the mixing is more uniform. When using the mortar dry powder mixer, follow the equipment instructions

According to the recipe requirements, gradually add an appropriate amount of water to the mixing container.

Use a mortar dry powder mixer to mix the water and raw materials until the mortar reaches a uniformly moist state.

Pay attention to gradually controlling the amount of water when adding water to prevent the mortar from being too thin or too dry.

The mixing time depends on the specific situation. Generally, it needs to be stirred for 2-5 minutes to ensure that the mortar is fully mixed.

During the mixing process of the mortar dry powder mixer, you can stop the machine timely to check the uniformity and moistness of the mortar. If necessary, you can adjust the amount of water or continue mixing.

Pour the mixed mortar into the construction site and perform masonry, filling or repair work as needed.

During the construction process, pay attention to controlling the amount of mortar and construction speed to prevent the mortar from drying out prematurely or losing its plasticity during the construction process.

Follow the mortar formula and construction requirements, and measure and mix raw materials in strict accordance with the proportions.

When adding water, control the amount gradually to prevent the mortar from being too thin or too dry.

The mixing time should be sufficient to ensure that the mortar is fully mixed and evenly distributed.

During the construction process, use the mixed mortar in time to prevent the mortar from drying out prematurely and losing its plasticity.

Through the correct configuration process, dry mortar with stable quality and good performance can be obtained to meet the needs of construction projects. In actual operation, appropriate adjustments and improvements can be made based on specific conditions and experience to obtain the best construction results.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.