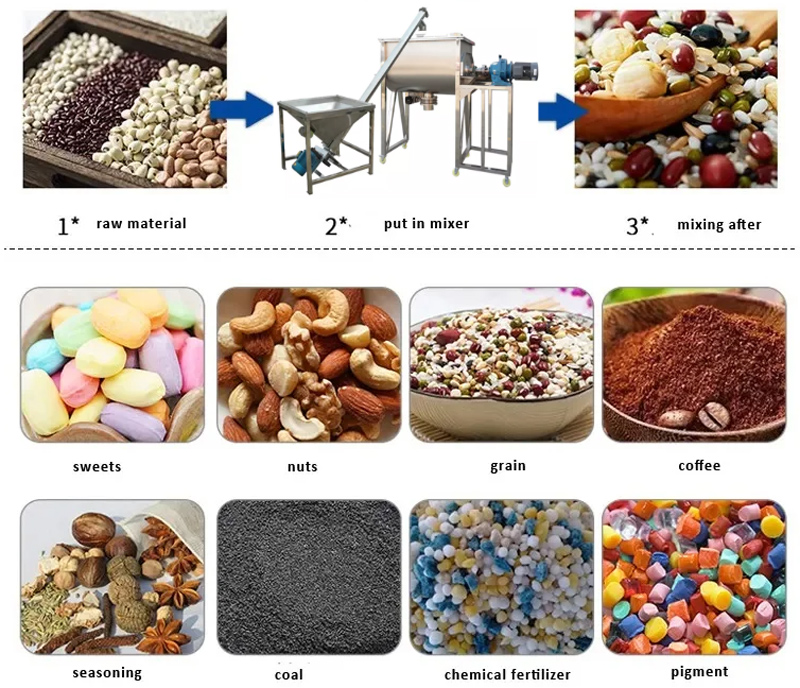

Stainless steel ribbon mixer is a common mixing equipment widely used in food, chemical, pharmaceutical and other industries. It uniformly mixes materials with different compositions and particle sizes through a ribbon structure to improve product quality and stability.

Food industry: Stainless steel ribbon mixers are widely used in the food industry. It can be used to mix flour, seasonings, dried fruits, nuts and other food ingredients. Through uniform mixing, the taste, color and aroma of food can be ensured to be uniform, improving product quality and market competitiveness.

Chemical industry: In the chemical industry, stainless steel ribbon mixers are used to mix chemical products such as powders, granules, pigments, and plastic granules. It can evenly mix materials with different components to achieve uniform chemical reactions and improve product quality and reaction efficiency.

Pharmaceutical industry: Stainless steel ribbon mixers have important applications in the pharmaceutical industry. It can be used to mix pharmaceutical raw materials such as pharmaceutical powders, tablets, and liquid medicines. Through uniform mixing, the ingredients of the drug can be ensured to be evenly distributed and the stability and efficacy of the drug can be improved.

Metallurgical industry: In the metallurgical industry, stainless steel ribbon mixers are used to mix metal powder, ore powder and other materials. It can uniformly mix powders of different components to achieve uniform metallurgical reactions and improve product quality and smelting efficiency.

Building materials industry: Stainless steel ribbon mixers are also widely used in the building materials industry. It can be used to mix cement, gypsum, fly ash and other building materials. Through uniform mixing, the strength, stability and construction performance of building materials products can be improved.

Environmental protection industry: In the environmental protection industry, stainless steel ribbon mixers are used to mix waste, sludge, sewage treatment agents and other materials. It can evenly mix materials with different components to improve processing effects and resource utilization.

Uniform mixing: The stainless steel ribbon mixer uses the ribbon structure to continuously turn and mix the materials, so that materials with different components can fully contact and mix, ensuring that the mixed materials are evenly distributed. This helps eliminate particle aggregation and stratification in the material and improves product uniformity and consistency.

Improve product quality: Through uniform mixing, the stainless steel ribbon mixer can ensure accurate proportions of various ingredients in the product and avoid local concentrations that are too high or too low. This helps improve product quality and ensures that each batch has the same performance and characteristics.

Promote reactions: In the chemical and metallurgical industries, stainless steel ribbon mixers are often used to mix reaction materials. By uniformly mixing the reaction materials, the efficiency and speed of the reaction can be improved and the chemical reaction can be promoted. This helps improve production efficiency and reduce production costs.

Improve process controllability: The stainless steel ribbon mixer has strong adjustability and can be adjusted according to different process requirements. By adjusting parameters such as mixing time, rotation speed and material feeding amount, material mixing with different mixing requirements can be achieved. This helps meet the process requirements of different products and improves the controllability of the production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.