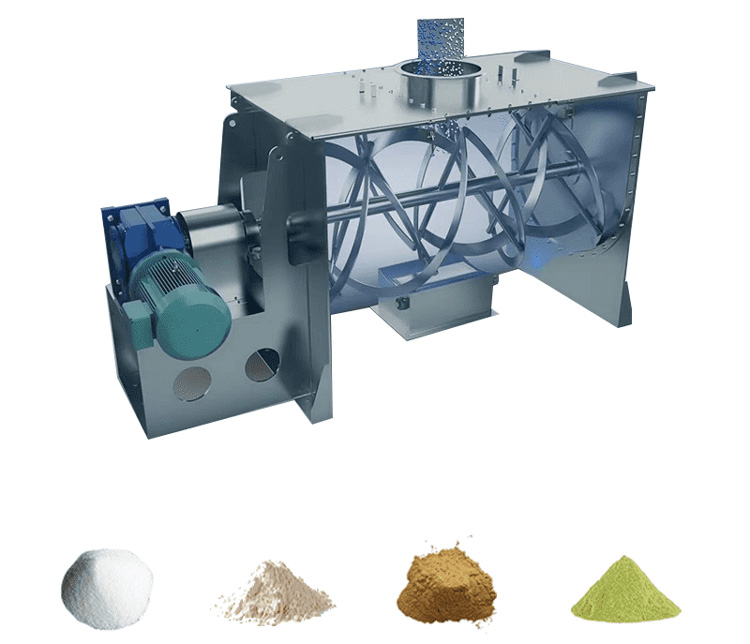

Cosmetic raw materials horizontal ribbon mixer is a kind of equipment used in cosmetic production, which is a mechanical equipment that mixes different kinds of cosmetic raw materials through a spiral propeller. Its design structure includes a horizontally placed spiral propeller, which is used to mix powder, granular or liquid cosmetic raw materials. This mixer can ensure that the cosmetic raw materials are evenly mixed inside the machine and ensure stable product quality.

Cosmetic raw materials for horizontal ribbon mixers is simple to operate, has high mixing efficiency, and can quickly mix different types of raw materials evenly. It plays a key role in cosmetic production, ensuring the full integration of various ingredients in the product formula, improving production efficiency, reducing production costs, and ensuring the quality and stability of the final cosmetic products.

Cosmetic raw materials for horizontal ribbon mixer is a kind of equipment that mixes different powder, granular or liquid raw materials. Its working principle mainly includes the following steps:

Feeding: Various cosmetic raw materials are put into the working chamber of the mixer according to the formula ratio.

Spiral mixing: The spiral propeller rotates inside the equipment to mix the raw materials. The spiral design allows the raw materials to be effectively stirred and mixed inside the machine, ensuring that various raw materials are fully mixed evenly.

Even mixing: Through continuous spiral stirring, the raw materials are gradually evenly mixed to ensure that the various ingredients in the cosmetic formula can be fully integrated.

Discharging: After mixing, the mixed cosmetic raw materials are taken out of the equipment for subsequent production processes.

Even mixing: The equipment uses a spiral propeller for mixing, which can fully mix the raw materials and ensure stable product quality.

High efficiency and energy saving: The ribbon mixer is easy to operate, has high mixing efficiency, and can save time and labor costs.

Wide applicability: It is suitable for different types of cosmetic raw materials, including powder, granular and liquid raw materials, and has strong versatility.

Safe operation: The equipment has a reasonable structural design, safe and reliable operation, and reduces the operating risks of the staff.

Convenient maintenance: The equipment is simple to maintain, easy to clean and maintain, and extends the service life of the equipment.

Ensure product quality: By evenly mixing different raw materials, ensure stable product quality and avoid stratification or uneven mixing of raw materials.

Improve production efficiency: The mixer is simple and efficient to operate, and can quickly complete the raw material mixing work, improve production efficiency, and shorten the production cycle.

Cost saving: The mixer mixes evenly, reduces raw material waste, and saves production costs.

Adapt to diversified needs: The horizontal ribbon mixer for cosmetic raw materials is suitable for different types of cosmetic raw materials and can meet the diversified needs in cosmetic production.

The mixing time of cosmetic raw materials for horizontal ribbon mixer depends on the nature of the raw materials and process requirements, usually between 5 minutes and 20 minutes. Cosmetic raw materials for horizontal ribbon mixer fully mixes the raw materials through a spiral propeller to achieve efficient and uniform mixing. The mixing efficiency is high, and the mixing uniformity can reach 99%. The equipment is simple to operate, the mixing effect is significant, the production efficiency is improved, time and cost are saved, and it is suitable for the mixing process requirements in cosmetic production.

In general, cosmetic raw materials for horizontal ribbon mixer is an indispensable equipment in cosmetic production. It ensures the stability of cosmetic product quality and improves production efficiency through efficient mixing, making important contributions to the development of the cosmetics industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.