Catalyst horizontal ribbon mixer is a kind of equipment for efficient and uniform mixing of various powdered or granular materials. It is widely used in chemical, pharmaceutical, food, building materials and other industries, especially suitable for the mixing of materials with high precision and high uniformity requirements such as catalysts. Catalyst for horizontal Ribbon Mixer consists of horizontal cylinder, double-screw agitator, driving device, etc., and the high-speed rotation of the screw ribbon can achieve full mixing of materials.

Catalyst for horizontal ribbon mixer achieves material mixing through the rotation of double screw ribbons. The outer screw ribbon pushes the material from both ends to the middle, and the inner screw ribbon pushes the material from the middle to both ends, thereby forming convection mixing in the mixing cylinder. In this complex movement process, the materials continuously shear, convect and diffuse with each other, and finally achieve uniform mixing.

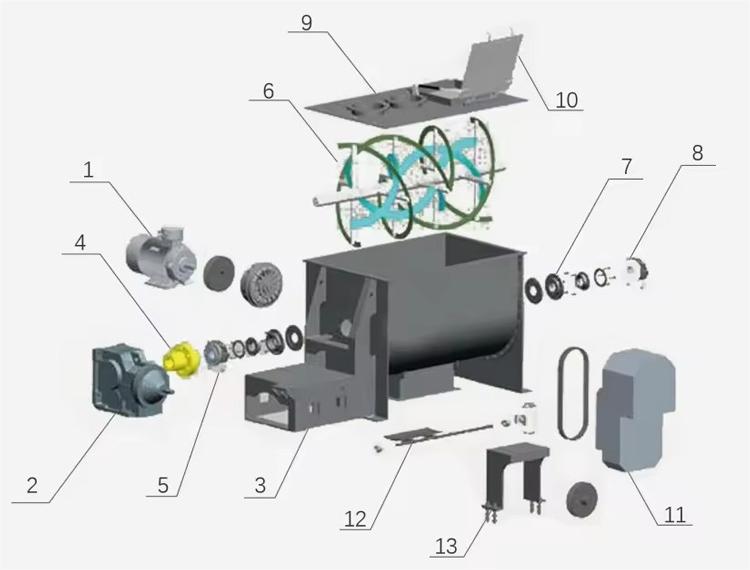

Catalyst for horizontal ribbon mixer adopts advanced design and reliable manufacturing technology to provide efficient and uniform mixing solutions. Its structure mainly includes the following points

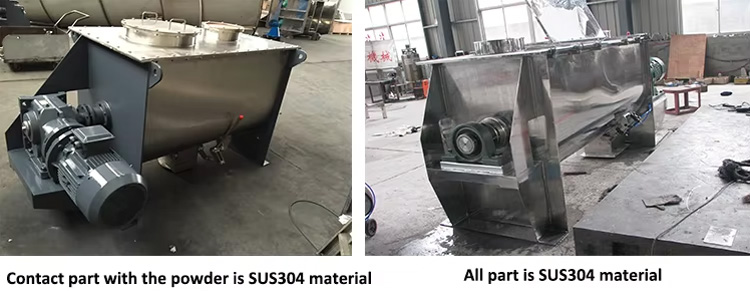

Horizontal cylinder: The cylinder is horizontal cylindrical, usually made of stainless steel or carbon steel, and has the characteristics of corrosion resistance and wear resistance.

Double-ribbon mixer: The mixer consists of two layers of inner and outer ribbons. The outer ribbon moves the material to one end, and the inner ribbon moves the material to the other end, forming a convection mixing effect.

Drive device: Usually composed of a motor and a reducer, providing the power required for the rotation of the ribbon.

Inlet and outlet: Used for loading and unloading materials, with reasonable design to ensure convenient operation.

Sealing device: Ensure that there is no material leakage during the mixing process, ensuring the safety and hygiene of the equipment.

Catalyst for horizontal ribbon mixer has a wide range of applications in catalyst applications. Catalysts are usually solid particles used to promote chemical reactions. The following are the applicable industries for horizontal ribbon mixer

Chemical industry: Catalyst for horizontal ribbon mixer is widely used in the chemical industry for mixing materials such as catalysts, dyes, pigments, additives, and resin powders. Its efficient mixing ability and good sealing performance ensure the uniformity and purity of the mixed materials, meeting the high-precision requirements of chemical production.

Pharmaceutical industry: In the pharmaceutical industry, catalyst for horizontal ribbon mixer is used to mix pharmaceutical raw materials such as drug powders and granules. The equipment is made of stainless steel, meets GMP requirements, and ensures the hygiene and safety of the drug production process.

Food industry: In the food industry, the equipment is used to mix various powdered or granular food raw materials, such as flour, milk powder, additives, etc. Its efficient and uniform mixing ability ensures the quality and taste of food raw materials.

Building materials industry: In the building materials industry, catalyst for horizontal ribbon mixer is used to mix building materials such as cement, gypsum, dry mortar, etc. The efficient mixing ability of the equipment improves the quality and performance of building materials products.

Catalyst for horizontal ribbon mixer is a mixing equipment widely used in industrial production. Its unique structural design and functional characteristics make it an ideal choice for material mixing. The following are some common advantages

Efficient mixing: Catalyst for horizontal ribbon mixer adopts double-screw design, with high mixing efficiency and short mixing time, which can quickly achieve the effect of uniform mixing.

High uniformity: The unique design of double-screw ribbon enables the material to continuously convect, shear and diffuse during the mixing process, ensuring the high uniformity of the material.

Easy operation: The equipment has a simple structure, easy operation, reasonable design of the inlet and outlet, fast loading and unloading of materials, and reduces the operation time and labor intensity.

Easy cleaning: The equipment is made of stainless steel, with a smooth surface, corrosion resistance, and easy cleaning. It is especially suitable for the pharmaceutical and food industries with high hygiene requirements.

Good sealing performance: The equipment is equipped with a good sealing device to ensure that there is no material leakage during the mixing process and to ensure the cleanliness and safety of the production environment.

Check before starting: Before using the catalyst for horizontal ribbon mixer, check whether the various parts of the equipment are intact, whether the fasteners are loose, whether the motor and reducer are normal, and ensure that the equipment is in good condition.

Operate according to regulations: The operation should be carried out strictly in accordance with the operating procedures of the equipment to ensure the safe operation of the equipment. Pay special attention to the operation of the inlet and outlet to avoid material leakage or uneven mixing.

Regular maintenance: During long-term use, the equipment should be regularly maintained and maintained, check the wear of each component, and replace the worn parts in time to ensure the normal operation and service life of the equipment.

Cleaning and maintenance: After use, the equipment should be cleaned in time, especially the cleaning of the mixing barrel and the spiral ribbon, to avoid material residue affecting the next use.

When cleaning, a cleaning agent that meets the material of the equipment should be used to avoid corrosion of the equipment.

As a high-efficiency and uniform mixing equipment, the catalyst horizontal spiral ribbon mixer is widely used in chemical, pharmaceutical, food, building materials and other industries. Its unique double-ribbon design and efficient mixing capacity can meet the mixing needs of various materials and ensure high uniformity and quality of materials. Through reasonable operation and maintenance, the catalyst for horizontal ribbon mixer can operate stably for a long time and provide reliable mixing solutions for the production of various industries.

Xinxiang Dahan is a well-known manufacturer specializing in the production of catalyst horizontal ribbon mixers. The manufacturer has many years of production experience and technical accumulation, and is in a leading position in the field of catalyst mixing equipment. Xinxiang Dahan's catalyst horizontal ribbon mixer has high mixing efficiency, precise control system and reliable performance, and is widely used in chemical, environmental protection and other industries. Dahan manufacturer pays attention to product quality and customer needs, provides customized solutions, and provides customers with high-quality products and professional after-sales service. Dahan is known for its innovation, reliability and high performance, and is one of the trustworthy manufacturers in the field of catalyst horizontal ribbon mixers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.