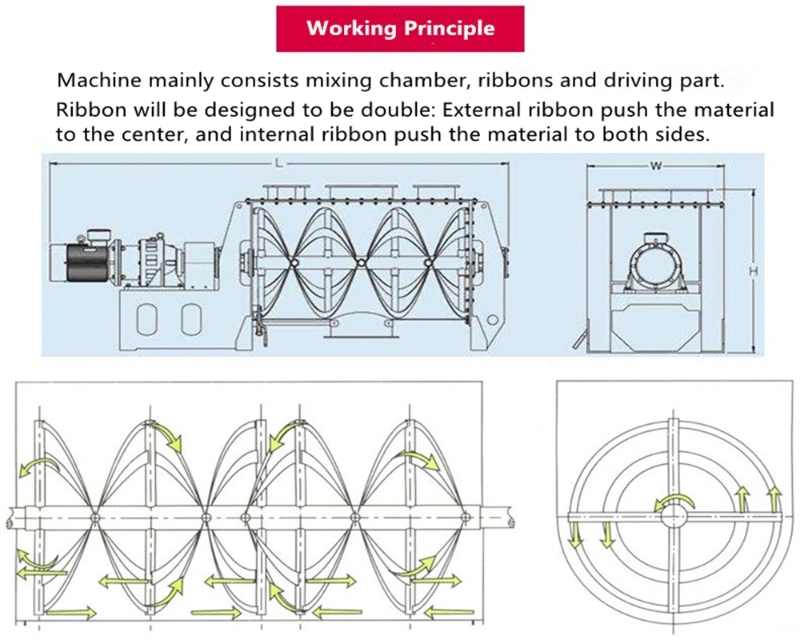

Ribbon mixer is a common industrial mixing equipment, widely used in chemical, food, pharmaceutical and other industries. The ribbon mixer uses a spiral blade mixing device. Its working principle is to evenly mix different materials together by turning and moving the spiral blades.

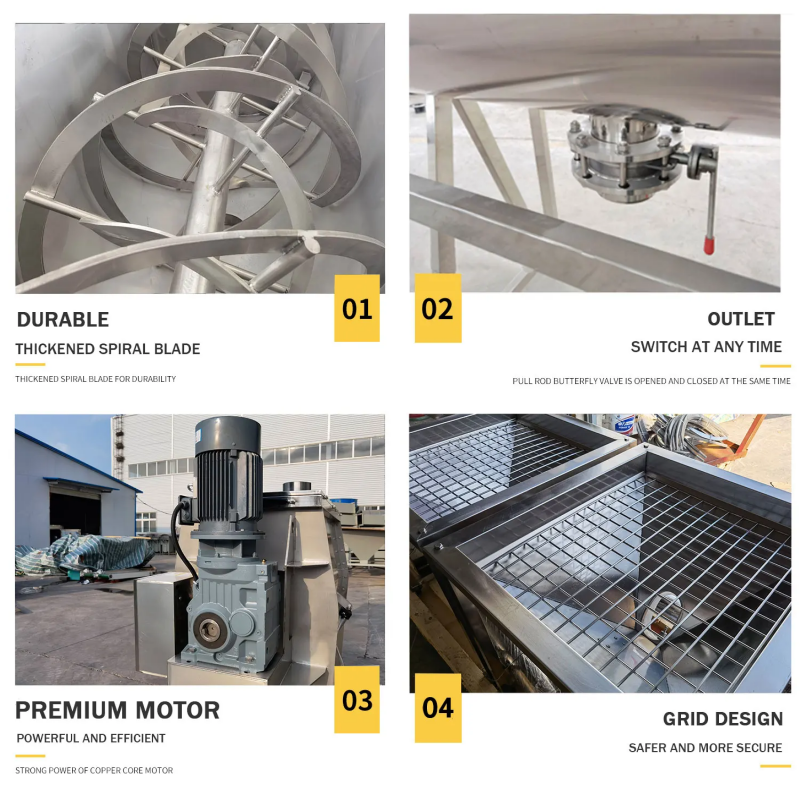

The main components of the ribbon mixer include mixing barrel, spiral blades, transmission device and motor. The mixing barrel is a mixing container, usually made of stainless steel and has good corrosion resistance and wear resistance. The spiral blade is a mixing stirring device, usually composed of two or more spiral blades, which can be fixed on the main shaft or connected to the main shaft.

The working process of the ribbon mixer is as follows:

1. Start the motor: First, start the motor and transmit the power to the spiral blades through the transmission device. The start of the motor causes the spiral blades to start rotating, generating stirring force.

2. Add materials: Add the materials to be mixed into the mixing barrel through the feed port. Materials can be in different forms such as powders, granules, liquids, etc.

3. Mixing process: The rotation of the spiral blades causes the materials to continuously turn and move in the mixing barrel. The spiral shape of the spiral blades enables the materials to be evenly distributed during the mixing process. The materials continuously rise, fall, rotate and move in the mixing barrel to achieve mixing of materials.

4. Mixing time control: As needed, the mixing effect can be adjusted by controlling the mixing time. The length of mixing time will affect the mixing degree of materials and can be adjusted according to different materials and process requirements.

5. Mixing completed: When the material reaches the predetermined mixing requirements, turn off the motor and stop stirring. Then, open the discharge port and take out the mixed materials.

The working principle of the ribbon mixer is based on the stirring effect of the spiral blades. The materials are mixed by the flipping and moving of the spiral blades. The spiral shape of the spiral blade enables the material to be evenly distributed during the mixing process, thereby achieving uniform mixing of the material. Ribbon mixers have the advantages of good mixing effect, stable and reliable operation, and easy operation. They are widely used in mixing processes in various industries.

It should be noted that when using a ribbon mixer, the appropriate mixing speed, mixing time and mixing capacity should be selected according to the specific material characteristics and process requirements to ensure that the mixing effect reaches the expected goal. In addition, for some viscous or highly viscous materials, additional measures, such as heating or humidification, may be required for better mixing.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.