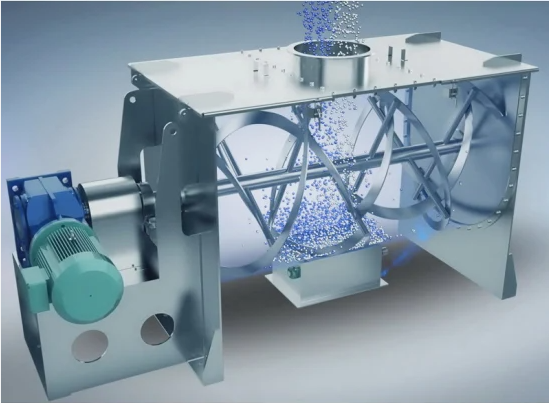

The industrial fertilizer for ribbon mixer is a fertilizer mixing equipment specially designed for the industrial field. It adopts the structure of spiral blades and spiral belts to evenly mix different types of industrial fertilizer particles through pushing, turning and stirring. The equipment has the characteristics of simple structure, convenient operation and good mixing effect. The working principle of the equipment is based on the pushing, turning and stirring action of the spiral blades and ribbons. Through the application of this equipment, many customers have achieved significant improvements in mixing effects, thus improving product quality and market competitiveness.

Industrial fertilizer for ribbon mixers are widely used in the production process of chemical fertilizers, nitrogen-phosphorus-potassium compound fertilizers, organic fertilizers and other industrial fertilizers. It is suitable for formula mixing of industrial fertilizers and scenarios with high requirements on ingredient uniformity, and can meet the mixing needs of different users.

1. Uniform mixing: The pushing, turning and stirring effects of the spiral blades and spiral belts enable full contact and mixing between industrial fertilizer particles, ensuring that the mixed fertilizer particles have a uniform distribution of ingredients and avoiding stratification between particles. .

2. Simple structure: The industrial fertilizer ribbon mixer is composed of spiral blades, ribbons, transmission devices and support frames, and has a simple and compact structure. The disassembly, cleaning and maintenance of the equipment are relatively convenient, reducing the workload of the operators.

3. Easy to operate: The equipment adopts an automatic control system and is simple and convenient to operate. Users only need to set parameters such as mixing time and speed, and the equipment can automatically complete the mixing process, improving production efficiency.

4. Good mixing effect: The industrial fertilizer ribbon mixer uses the continuous pushing, turning and stirring functions of the spiral blades and ribbon to make the mixing effect more uniform and detailed. The mixed fertilizer particles not only have uniform composition, but also have improved physical properties between particles, improving the quality of the fertilizer and the fertilization effect.

1. Feeding: Industrial fertilizer particles enter the feed port of the mixer through a feeder or other conveying equipment.

2. Spiral blade pushing: The spiral blade is located inside the mixer and fixed on the spiral shaft. When the spiral shaft rotates, the spiral blades push the material forward. The pushing effect causes particles to collide and flip over each other, promoting the mixing effect.

3. Ribbon movement: The ribbon is located outside the spiral blades and moves in cooperation with the spiral blades. The movement of the ribbon increases the mixing degree of the particles, making the particles more evenly distributed inside the mixer.

4. Discharge: The mixed particles are discharged from the discharge port of the mixer. The discharge speed can be controlled by adjusting the opening and closing of the discharge port.

A chemical fertilizer manufacturer uses an industrial fertilizer for ribbon mixer to produce compound fertilizer. After using the equipment, they found that the mixing effect was significantly improved and the composition uniformity of the fertilizer particles was greatly improved. This enables them to produce compound fertilizer products of better quality and more uniform composition, improving the competitiveness and market share of their products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.