Animal and vegetable for oil feed stirring mixer is designed to precisely blend animal and vegetable oils with a variety of feed ingredients. The main unit is constructed of corrosion-resistant 304/316L stainless steel, meeting food-grade hygiene standards and ensuring a contamination-free oil mixing process. By optimizing the spiral belt spacing and roller-grinding mechanism, this model completely eliminates dead zones in the mixing process, effectively improving the uniformity of oil and fat blending with ingredients like corn and soybean meal, preventing the formation of fat globules and ensuring nutritional balance in the feed.

Our customizable Animal and vegetable for oil feed stirring mixer breaks through the limitations of traditional equipment with its innovative design to meet diverse production needs. The main unit is constructed of food-grade stainless steel. To address mobility challenges, we've incorporated a roller design, eliminating the need for fixed installation after use and allowing for easy transport to warehouses or clean areas, significantly saving space and labor costs. Performance-wise, it boasts a mixing time of just 8-15 minutes and can handle batches of 200-2000 kg. While ensuring high-speed production, its three-dimensional mixing technology ensures uniform mixing of oil and powder, preventing stratification and clumping. Whether it is liquid oils such as fish oil and soybean oil, or solid raw materials such as premixes and granular materials, ideal mixing effects can be achieved.

We offer both vertical and horizontal models, precisely tailored to the oil feed mixing needs of various scales and processes. Customization is also available, helping to improve feed homogeneity and production efficiency.

Vertical animal and vegetable oil feed stirring mixers: These mixers occupy a small footprint, consume low power, and can mix volumes from 50L to 800L per batch, making them suitable for small and medium-sized production runs in small farms and family farms. The material-contacting parts are constructed of stainless steel, allowing for flexible adjustment of stirring speed to suit the oil addition ratio. They are easy to move and meet basic oil feed mixing needs.

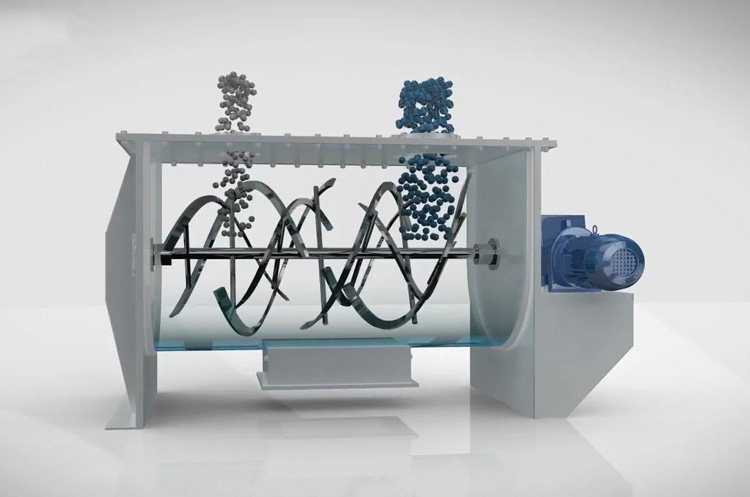

Horizontal animal and vegetable oil feed stirring mixers: These mixers can be equipped with either a twin-screw or twin-shaft paddle mixing system. The outer spiral pushes the material to the center, while the inner spiral pushes in the opposite direction, creating intense convective mixing. Mixing uniformity can exceed 95%, batch mixing can be completed in 2-6 minutes, and equipment residue is minimal. The capacity ranges from 500L to 5000L, supports continuous operation, and is suitable for mass production in large feed mills and scale ranches.

Animal and vegetable for oil feed stirring mixer can mix quickly, with reliable materials and easy movement. It is made of stainless steel and has high mixing uniformity. It supports non-standard customization and the addition of rollers.

Efficient mixing: The stirring mixer adopts a professionally designed stirring device, which can quickly and evenly mix raw materials such as animal and vegetable oils and fats to improve mixing efficiency.

Precise control: The equipment is equipped with an advanced control system, which can accurately control the mixing time, speed and temperature to ensure the mixing quality.

Reliable and stable: Made of high-quality materials, with a stable structure, stable and reliable operation, it ensures long-term and efficient work.

Versatility: In addition to animal and vegetable oils and fats, the stirring mixer can also be used to mix various feed raw materials to meet the needs of different formulas.

Animal and vegetable for oil feed stirring mixer mixes various feed raw materials through a stirring device. When the equipment is started, the stirring device rotates to fully stir and turn the feed raw materials inside the mixer to achieve uniform mixing between the raw materials. For viscous and easily solidified materials such as animal and vegetable oils, the design of the stirring mixer usually takes into account functions such as heating and heat preservation to ensure that the raw materials remain fluid during the mixing process and avoid solidification affecting the mixing effect.

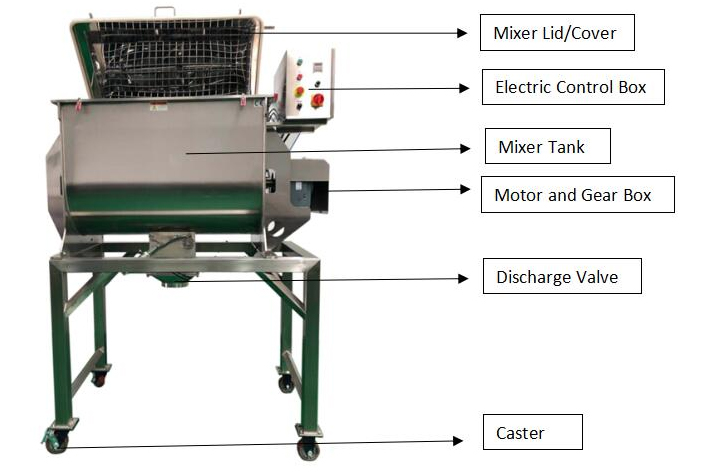

Animal and vegetable for oil feed stirring mixer is driven by blade and ribbon rotor, stainless steel body with hydraulic discharge door, integrated liquid addition pipeline and universal wheel design, which can achieve the mixing and flexible movement of powder and granular materials, oil and high viscosity materials.

Mixing chamber: It is the space where feed and animal and vegetable oils are mixed, generally made of stainless steel or other corrosion-resistant materials.

Stirring device: It includes stirring blades, spiral blades or rotors, etc., which are the core components of the mixer.

Drive system: It is composed of motor, reducer, etc., which provides power for the mixing device and transmits the rotation of the motor to the mixing device through a transmission device (such as a belt, chain or gear).

Feed inlet and discharge inlet: The feed inlet is used to add feed raw materials and animal and vegetable oils, and the discharge inlet is used to discharge the mixed feed.

Control system: It can realize the functions of starting, stopping, speed adjustment, mixing time setting, etc. of the mixer.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Animal and vegetable for oil feed stirring mixer This equipment realizes oil emulsification, powder infiltration and micro-agglomerate dispersion through the dual effects of spiral shearing and roller crushing, solving the problems of easy agglomeration and nutrient stratification in traditional mixing.

Even mixing: The stirring mixer can evenly mix various animal and vegetable oil feed raw materials, ensure the appropriate proportion of various ingredients in each portion of feed, and improve the quality and uniformity of the feed.

Improve the taste of feed: By stirring and mixing, the various ingredients in the feed can be mixed evenly, thereby improving the taste of the feed and increasing the acceptance of the animal to the feed.

Improve production efficiency: The stirring mixer can quickly and efficiently complete the mixing process of raw materials, improve production efficiency, save time and labor costs.

Ensure balanced feed nutrition: By mixing different types of raw materials, the balance of various nutrients in the feed can be ensured to meet the growth and development needs of animals.

With its powerful shearing and dispersing capabilities and multi-form adaptability, the animal and vegetable oil feed stirring mixer can handle a wide range of feed mixing needs. Its stainless steel construction and customized design further ensure a stable mixing process, making it particularly suitable for processing high-fat or sticky materials.

Liquid + Powder: For example, when mixing animal fats with powders such as fish meal and bone meal, the spiral belt and rollers work together to evenly coat the powder particles with the fat, preventing clumping and improving feed palatability and nutritional density.

Liquid + Granule: Suitable for mixing vegetable oil with coarse feeds such as corn kernels and soybean meal pellets. The high-speed rotating paddles and rollers penetrate the fat into the pellet surfaces and crevices, ensuring consistent oil content in each feed and preventing oxidation and stratification.

Powder + Granule: Suitable for mixing vitamin premixes, mineral powders, and extruded pellets. The multi-stage mixing structure breaks up powder agglomerates and evenly adheres the powder to the pellet surfaces.

Animal and vegetable for oil feed stirring mixer equipment, with its advantages of high-speed mixing, corrosion-resistant materials, and flexible customization, has successfully served family farms, large-scale breeding groups, and premix companies, solving pain points such as oil agglomeration and uneven mixing, and achieving both production capacity and quality improvements.

Ruminant breeding bases:Steam-exploded straw needs to be mixed with animal and vegetable oils, molasses, and other ingredients to create a complete mixed fodder. The introduction of a customized horizontal twin-ribbon mixer, using convection mixing from the inner and outer ribbons, ensures uniform coating of oil and straw fibers, eliminating the problems of traditional mixed oils clumping and picky feeding by livestock. Adding a temperature control module to the equipment stabilizes oil flowability, increasing mixing uniformity to 92%.

Large-scale laying hen farms:Specialized feed needs to be prepared by mixing raw materials such as corn and soybean meal with animal and vegetable oils and antioxidants. A 2-ton single-shaft ribbon mixer is equipped with a heated oil addition system. A high-precision batching scale controls the raw material ratio, while the multi-directional rotation of the twin ribbons ensures even oil penetration into the powder. This reduces mixing time to just 4 minutes, achieving over 93% uniformity.

Aquatic feed factories:Fish oil and other animal fats must be precisely added after extrusion. A customized vertical spray mixer is used. Its unique spray structure atomizes the oil and evenly sprays it onto the pellet surface. Combined with drum agitation, it achieves seamless coating. The equipment supports adjustable mixing times from 0 to 30 minutes, adapting to production lines with a throughput of 3 to 6 tons per hour.

In the feed production process, the addition of animal and vegetable oils (such as soybean oil, fish oil, palm oil, etc.) can significantly improve the energy value and palatability of the feed. In order to ensure that the oil and feed are evenly mixed, it is necessary to select a suitable animal and vegetable oil feed mixer. The following are the criteria that need to be considered when purchasing.

Mixing uniformity: The mixing uniformity (CV value) of oil and feed should be ≤5% to ensure that the nutritional content of each batch of feed is consistent.

Corrosion resistance: Animal and vegetable oils may contain free fatty acids, which will corrode the equipment if in contact for a long time. The material is 304/316 stainless steel (better than carbon steel).

Sealing: Anti-leakage design, mechanical seal at the shaft end (to avoid grease leakage). Sealing strips should be installed on the observation window and inspection port to prevent feed powder from entering the grease system and causing blockage.

Heating and insulation function: In low temperature environment (such as winter), grease is easy to solidify, and interlayer heating (steam/electric heating) and insulation layer design can be added (to reduce heat loss).

Automation degree: Automatic oil injection system: precise control of oil injection amount (error ±1%), PLC control, can set mixing time, temperature, and oil injection speed.

Dahan Machinery Manufacturing Co., Ltd. is a well-known manufacturer specializing in the research and development of animal and vegetable oil feed stirring mixers. The independently developed "double-shaft paddle oil mixer" is made of 304 stainless steel, equipped with an intelligent temperature control system and a high-pressure atomization oil injection device, with a mixing uniformity CV value of ≤3% and an grease addition accuracy error of ±0.5%. The product has passed ISO9001 certification and CE safety certification, has a triple mechanical seal leak-proof design, supports PLC full-automatic control, has a single batch processing capacity of 1-15 tons, and provides a 2-year warranty and 48-hour after-sales response service.

Animal and vegetable for oil feed stirring mixer are key equipment for ensuring the quality of oil feed. Through precise mixing, they achieve a uniform blend of oil and feed ingredients, improving feed palatability and nutrient absorption while reducing losses. Whether it's a compact, economical, and convenient vertical model suitable for small- to medium-sized farms, or a horizontal model with high-speed mixing and high uniformity, meeting the mass production needs of large feed mills, both can be customized to provide stable, high-quality oil feed for various livestock, poultry, and aquatic species.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.