Stainless steel feed mixer is a piece of equipment used to mix different types of feed ingredients. It is made of stainless steel and has the characteristics of corrosion resistance, easy cleaning, non-toxic and odorless, which can ensure the hygiene and quality of the feed during the mixing process. Below is a detailed explanation of the working principle of the stainless steel feed mixer.

Loading: First, put the feed ingredients to be mixed into the hopper of the stainless steel mixer according to a certain proportion and formula. The hopper is usually located on top of the machine and can be filled manually or automatically.

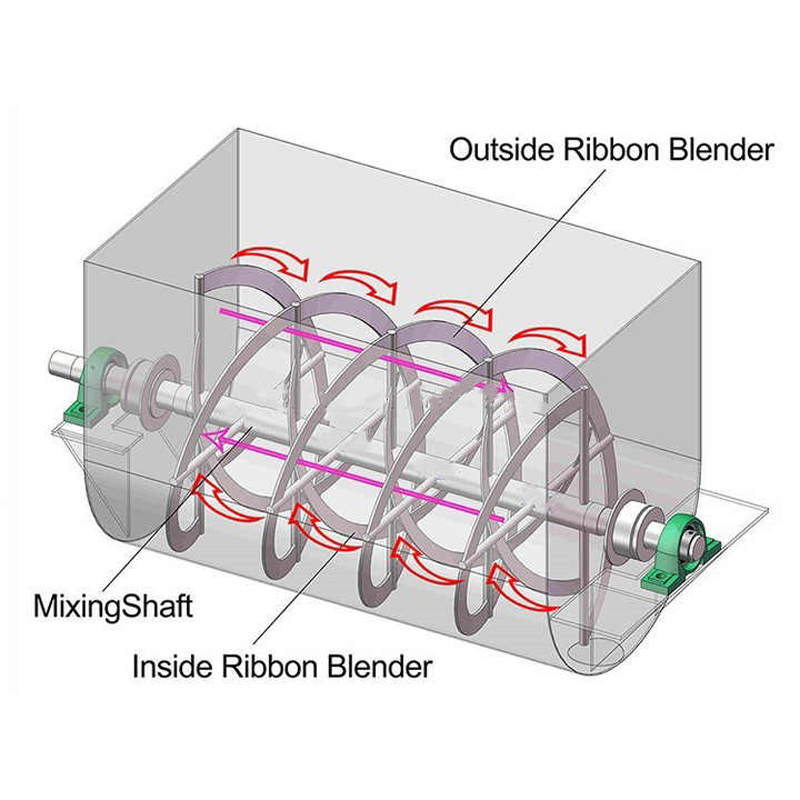

Mixing process: Once the feed ingredients are loaded into the hopper, the stainless steel mixer starts working. The machine is equipped with mixing blades or mixing devices, which mix feed ingredients by rotating or stirring. The mixing blade is usually located on the bottom or side of the machine and can rotate in a horizontal or vertical direction. The stirring device can be a rotating stirring arm or a stirring paddle, and the feed ingredients are thoroughly mixed by stirring.

Time and speed control: The time and speed during the mixing process can be controlled as needed. Typically, the mixing time is short and the mixing process can be completed within a few minutes. The mixing speed can be adjusted to ensure that the feed ingredients are fully mixed, but at the same time, it is necessary to avoid over-mixing that causes the feed ingredients to break or deform.

Adding auxiliary materials: During the mixing process, it is sometimes necessary to add some auxiliary materials, such as vitamins, minerals, enzymes, etc. These materials can be added to the mixer through special devices or pipes and mixed with feed ingredients.

Temperature and humidity control: For some specific feed ingredients, such as pellet feed or feed with added liquid ingredients, temperature and humidity also need to be controlled. During the mixing process, the temperature of the feed can be adjusted by heating or cooling devices to maintain its stability. Humidity control can be achieved by adding water or spraying to bring the feed to the required humidity.

Unloading: After mixing is completed, the stainless steel mixer will automatically or manually unload the mixed feed ingredients from the machine. The discharge port is usually located at the bottom of the machine, and the feed can be smoothly discharged by opening the discharge door or other devices.

Cleaning and Maintenance: After each use, stainless steel feed mixers require cleaning and maintenance to ensure hygiene and proper operation of the equipment. Cleaning can be carried out by flushing and brushing, and various parts of the machine also need to be inspected and maintained regularly to ensure their normal operation.

To sum up, the stainless steel feed mixer puts different types of feed ingredients into the machine and uses mixing blades or mixing devices to fully mix them, and finally obtains uniform mixed feed. This kind of equipment is widely used in the livestock breeding industry and can improve feed quality and production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.