Designed for small scale mixing tasks, for mixing small batches of material for research, development or testing purposes.

![]()

![]()

Price:$300.00-$2,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-15min

Loading Capacity: 0.6-100kg

Voltage: 120V/220V/380V/440V/CUSTOMIZABLE

Power: 0.75 kW

Material: SUS304, SUS316L

Application: Suitable for small production areas or laboratories for mixing pharmaceutical ingredients, seasonings, spices, food powders, chemical raw materials, feed, pigments and additives, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Small mixer machines are compact, efficient devices designed for mixing various substances in smaller quantities. They are commonly used in laboratories, kitchens, workshops, and other settings where precise mixing is required.

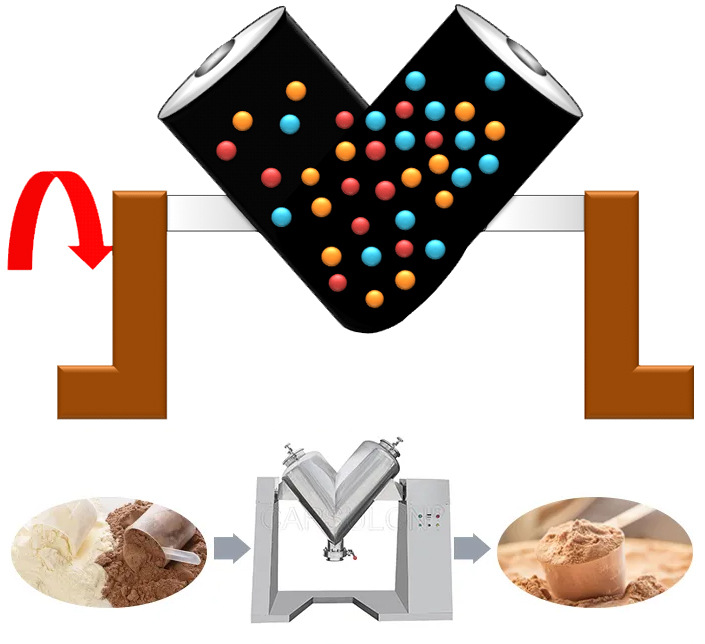

Small mixer machine mixing capacity is usually between 1 kg and 100 kg, V-shaped structure design, the material is constantly turned over during the mixing process, the mixing effect is good, suitable for small processing and home use, used to mix different types of materials, such as food ingredients, seasonings, medicines, cosmetics, etc.

Small mixer machines provide cost-effective solutions for businesses that need to efficiently mix small quantities of materials. They offer versatility, convenience, and ease of use:

Laboratory Uses: They are commonly used in laboratories to mix small batches of materials for research, development, or testing purposes.

Pharmaceutical Industry: These mixers are used to mix pharmaceutical powders, granules, and other ingredients in drug production.

Food Industry: They are used in food processing to mix ingredients such as spices, seasonings, and food additives.

Cosmetic Industry: They are used in the cosmetic industry to mix various cosmetic ingredients to make products such as creams, lotions, and makeup.

Chemical Industry: They are used to mix chemicals, dyes, pigments, and other substances in small-scale chemical production processes.

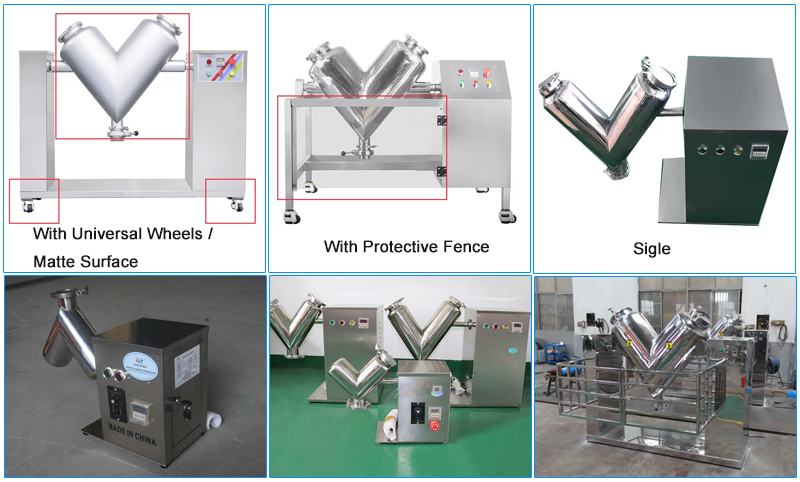

Small mixer machines are usually used in laboratories, small-scale production or home use. The following are several common types of small mixers:

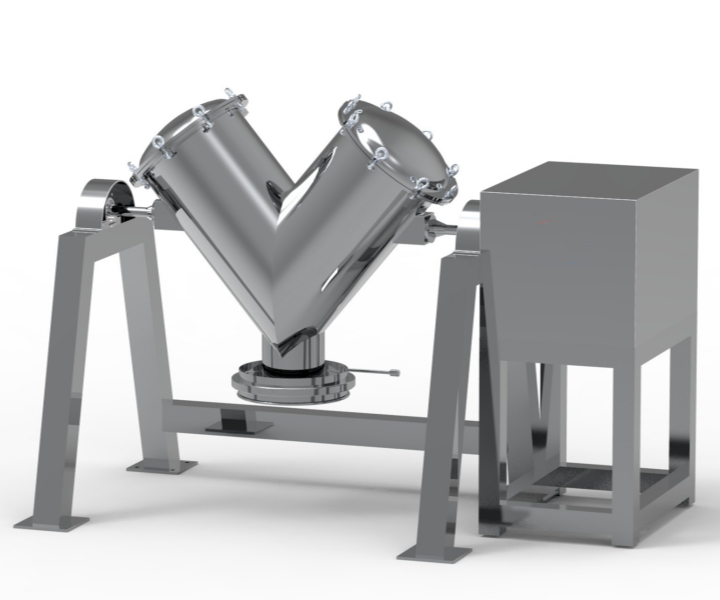

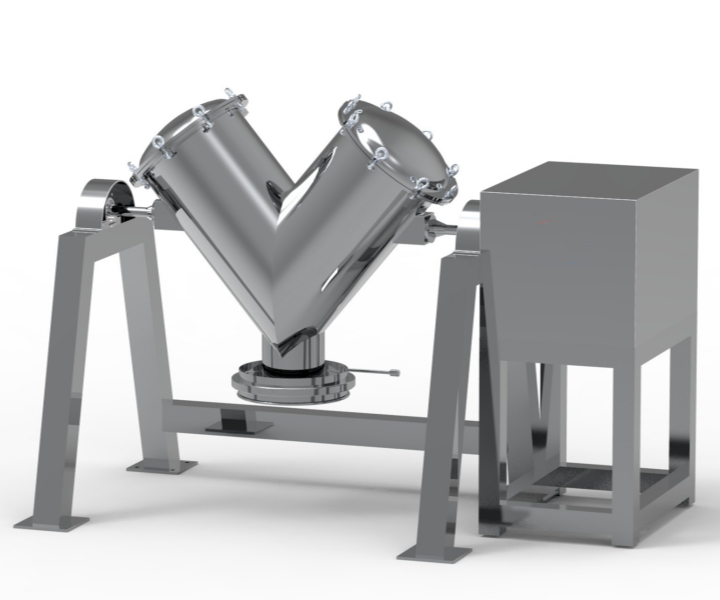

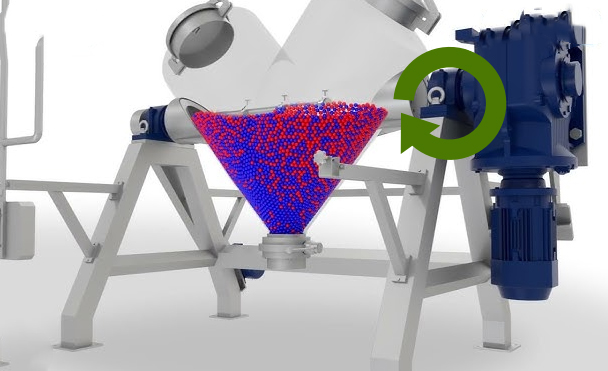

V-type small mixer machine: The container of the V-type small mixer machine is V-shaped, with a stirrer or stirring blades inside, which mixes the materials evenly by rotating and stirring. Suitable for mixing powdered or granular materials.

Drum small mixer machine: Drum small mixer machine consists of a rotating drum and an internal stirrer, which mixes the materials evenly in the drum. Suitable for mixing granular or powdered materials.

Double cone small mixer machine: Double cone small mixer machine consists of two conical containers, which mix the materials evenly in the container by rotating. Suitable for mixing powdered, granular or viscous materials.

Screw small mixer machine: Screw small mixer machine mixes the materials along the spiral direction through a spiral stirrer, which is suitable for mixing granular or powdered materials.

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

The mixing capacity of small mixers can vary according to different models and designs. Here are some common small mixer mixing capacities

10kg to 50kg: Suitable for laboratories or small batch production, powdered or granular chemicals, food additives, pigments, resin powders can be mixed together.

20kg to 100kg: Commonly used in small production, food processing mixed powder or granular materials, for mixing pharmaceutical raw materials, agricultural particles, pigment powders.

30kg to 150kg: Used in viscous material mixing and chemical production, suitable for colloidal materials, high viscosity liquids, paints, glues, colloidal solutions, etc.

Compact and Portable

Small mixer machines are usually compact and lightweight, making them easy to carry and store. This makes them ideal for use in small spaces such as home kitchens, laboratories and small workbenches.

Efficient and time-saving

Small mixer machines usually have high rotation speed and stirring capacity, and can quickly mix and stir various substances. Compared with manual mixing, they can greatly shorten the mixing time and improve work efficiency.

Versatility

Small mixer machines often come with different types of mixers and attachments to accommodate different mixing needs. For example, you can use different mixers to beat egg whites, mix batter, mix seasonings, etc. This versatility makes small blenders very useful in different areas of application.

Easy to operate

Small mixer machines usually have simple operating interfaces and control buttons, making them easy to use. Just put the materials to be mixed into the container, select the appropriate mixing speed, and press the start button to start mixing. This makes it easy for anyone to get started.

Safe and reliable

small mixer machines usually have safety designs, such as splash-proof covers, anti-slip bases, etc. These designs can reduce splashes and accidents during the mixing process and ensure user safety.

Improve product quality

The small mixer machine can evenly mix various materials to ensure product quality and consistency. They effectively blend solids and liquids together, resulting in better taste, texture and stability of the final product.

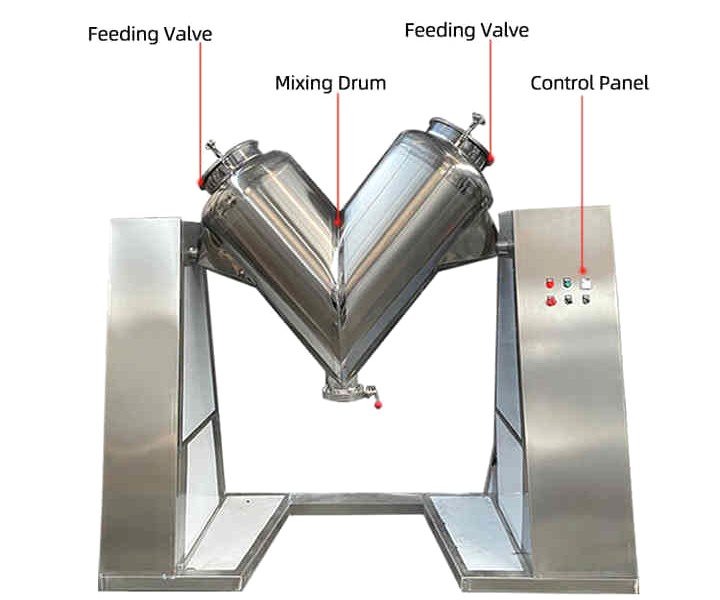

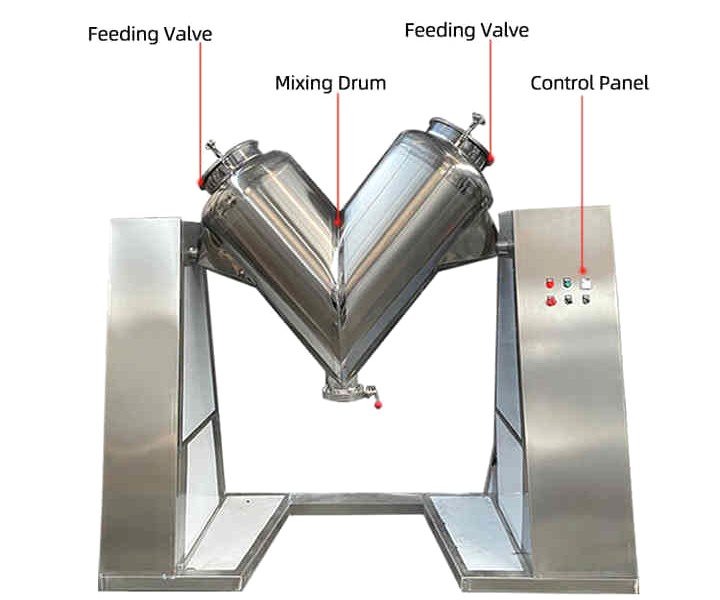

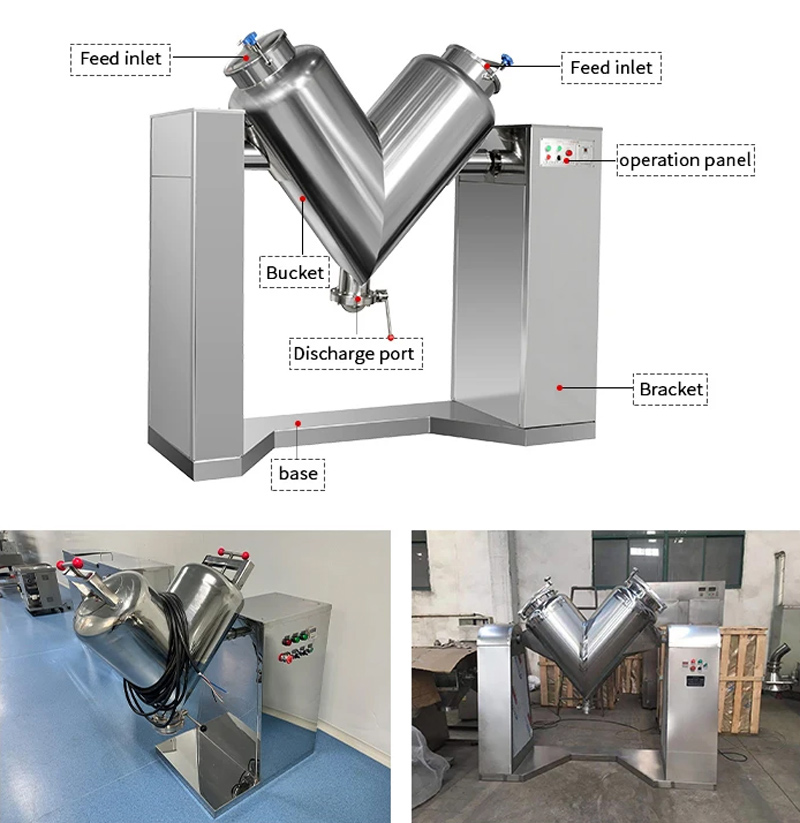

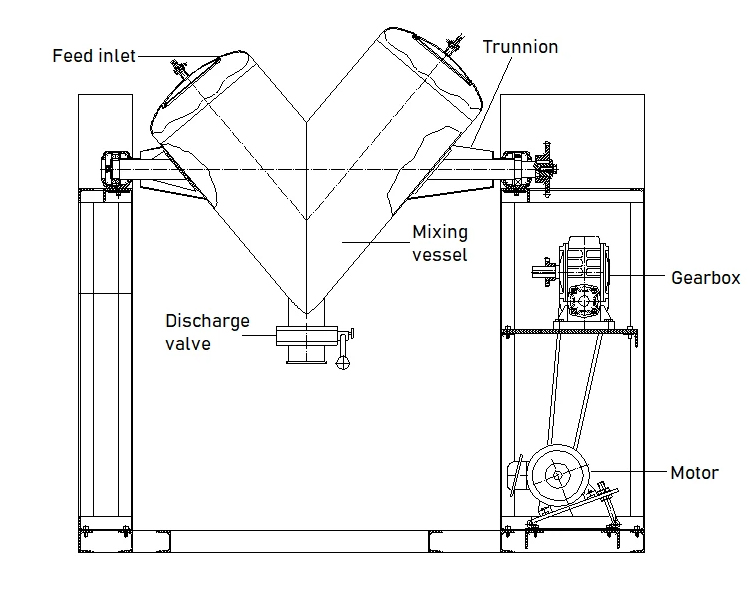

The structure of the small mixer machine is relatively simple and mainly consists of the following parts:

V-shaped container: The V-shaped container is the main part of the small mixer machine, usually made of stainless steel or carbon steel.

Mixing blades: The mixing blades are located inside the V-shaped container, usually two or more. The mixing blade is fixed on the shaft and rotates driven by the motor.

Motor and transmission: The motor is the power source that drives the mixing blades to rotate, and is usually installed at the bottom or side of the mixer. The motor transmits power to the mixing blade through the transmission device, causing it to rotate.

Control system: The control system is used to control the start, stop and speed regulation of the motor.

The small V-shaped mixer uses a specially designed bidirectional rotating agitator inside the V-shaped container to push the material to the center from two directions at the same time, achieving rapid mixing and uniform distribution of the material. The continuous rotation and flipping action of the agitator allows the material to constantly exchange positions in the V-shaped container, thereby achieving an efficient mixing process.

| Model | Type | Dimension | Packing Weight | ||

| VH-2 | single arm | 420*330*390 (mm) |

16.54*12.99*15.35 (inch) |

20 (kg) |

44.09 (lbs) |

| VH-5 | single arm | 560*460*650 (mm) |

22.05*18.11*25.59 (inch) |

57 (kg) |

125.66 (lbs) |

| VH-8 | single arm | 580*560*650 (mm) |

22.83*22.05*25.59 (inch) |

60 (kg) |

132.28 (lbs) |

| VH-10 | single arm | 970*410*880 (mm) |

38.19*16.14*34.65 (inch) |

62 (kg) |

136.69 (lbs) |

A cosmetics company called Beauty Cosmetics Co., Ltd. focuses on producing high-quality cosmetics products. In order to improve product uniformity and quality, they decided to introduce a small mixer machine. This mixer features a special V-shaped agitator and rotating container that quickly mixes different powder and liquid ingredients together. The company uses small mixer machines in the preparation process of cosmetic formulas. They only need to put the powder and liquid ingredients that need to be mixed into the container, start the mixer, and the small mixer machine starts to rotate and mix the materials evenly. By using small mixer machines, Beauty Cosmetics Company found that the mixing process was more efficient, saving a lot of time and labor costs. At the same time, the special design of the small mixer machine ensures the uniformity of mixing, making the final cosmetic product quality more stable and consistent. This small mixer machine has become an important piece of equipment on the beauty cosmetics company's production line, helping them improve production efficiency and product quality, meeting customers' needs for high-quality cosmetics, and further consolidating their competitive position in the market.

When choosing a small mixer machine, you need to consider several factors to ensure that you choose the right equipment for your needs. The following are the key factors you should consider when choosing a small V-type mixer:

1. Mixing capacity: Determine the amount of material you need to mix each time, and choose a mixer capacity that suits your production needs. The capacity of a small mixer machine usually ranges from tens of liters to hundreds of liters.

2. Mixing effect: Consider your requirements for mixing effect and ensure that the selected mixer can evenly mix various types of materials, including powders, granules, etc.

3. Mixing method: Including the design of the agitator or mixing blades, as well as the adjustability of the mixing speed and mixing time.

4. Control system: Make sure the mixer is equipped with a simple and easy-to-use control system that can adjust the mixing speed, time and other parameters to meet different mixing needs.

As your small mixer supplier, choosing us as your small mixer supplier will give you high-quality products, professional services and all-round support to help you achieve your production goals and succeed.

Precision manufacturing: Our small mixers use high-quality materials and advanced technology to ensure equipment durability and efficiency.

Strict quality inspection: Each device undergoes strict quality inspection before leaving the factory to ensure stable and reliable performance.

Multiple capacities: Provide different capacity models from 100 grams to 1500 grams to meet various needs such as laboratories and small batch production.

Multifunctional design: Suitable for mixing powders, granules, liquids and high-viscosity materials to meet the needs of different industries.

Customized service: Provide customized solutions according to the special needs of customers.

Quick response: Professional after-sales team provides 24/7 technical support to quickly solve customer problems.

International layout: Products are exported to many countries and regions around the world, and the service network covers a wide range.

Clear quotation: Provide transparent prices and detailed contract terms to eliminate hidden charges.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.