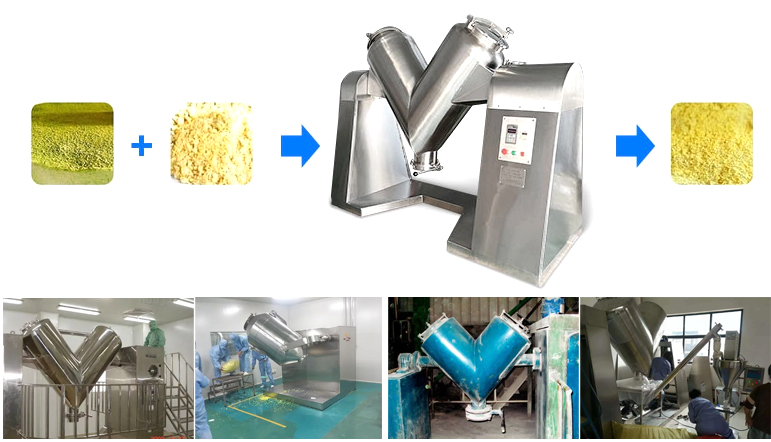

An equipment for efficiently mixing feed raw materials, which achieves uniform mixing of feed through the movement of the rotating drum and mixing blades.

![]()

![]()

Price:$300.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-15min

Max. Loading Capacity: 10kg

Max. Loading Volume: 8 L

Voltage: 120V/220V/380V/440V/CUSTOMIZABLE

Material: SUS304, SUS316L

Application: Ideal for small farms or operations with limited space, it is capable of mixing a variety of feed ingredients including grains, vitamins, minerals and additives for cattle feed, pig feed, sheep feed, chicken feed, aquaculture feed, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Small rotary drum feed mixer is a compact agricultural machine designed for mixing various types of animal feed ingredients. It typically consists of a cylindrical drum that rotates horizontally or inclined at a slight angle. The feed ingredients, such as grains, minerals, vitamins, and additives, are loaded into the drum, and as it rotates, the ingredients are mixed thoroughly to create a uniform blend.These mixers are commonly used in small-scale livestock operations, such as on small farms or homesteads, where customized feed formulations are required for different animals.

The equipment is flexible and convenient, making it suitable for small-scale feedlots or family farming environments. It can effectively mix different types of feed ingredients to ensure the balance and consistency of each feed. The small rotary drum feed mixer can meet different feed needs by adjusting the mixing time and speed, provide high-quality feed supply, and help improve the growth performance and health of animals. Whether you are a family farmer or a small farm, you can use this equipment to improve feed quality and provide a nutritionally balanced feeding environment.

Small rotary drum feed mixer has a wide range of application scenarios in the feed processing industry. Here are some common application scenarios:

Poultry farms: Small rotary drum feed mixer is suitable for poultry farms, such as chicken farms, duck farms, goose farms, etc. It can mix different types of feed ingredients to produce nutritionally balanced feed, improving the growth rate and breeding efficiency of poultry.

Livestock farms: For livestock farms, such as pig farms, cattle farms, sheep farms, etc., it can mix a variety of feed raw materials to produce feed suitable for different growth stages, improving the growth and development and meat quality of livestock and poultry.

Breeding cooperatives: Small rotary drum feed mixer is also suitable for breeding cooperatives or farmers' cooperatives. By mixing different feed ingredients, feed that meets the needs of members can be produced according to the breeding needs, improving breeding efficiency and economic benefits.

Farms and feed mills: Small rotary drum feed mixer can also be used on farms and feed mills. It can mix crop straw, feed crumbs, additives and other raw materials to produce high-quality feed products to meet market demand.

Seed and fertilizer processing: In addition to feed processing, the small rotary drum feed mixer can also be used for seed and fertilizer mixing processing. It can mix different types of seeds and fertilizers to improve fertilization effect and crop yield.

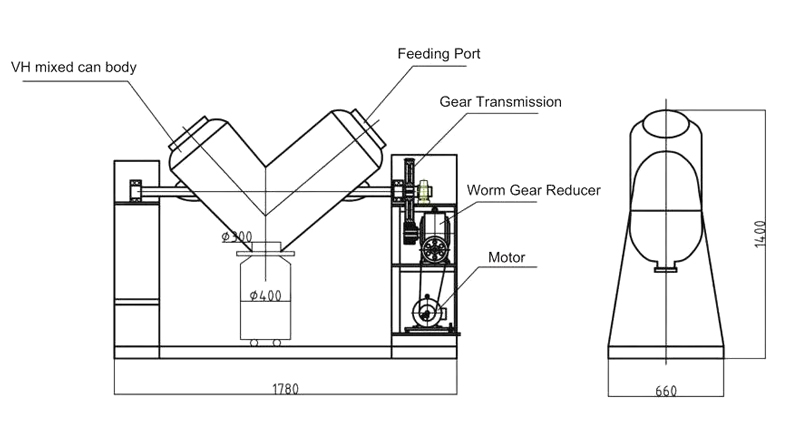

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

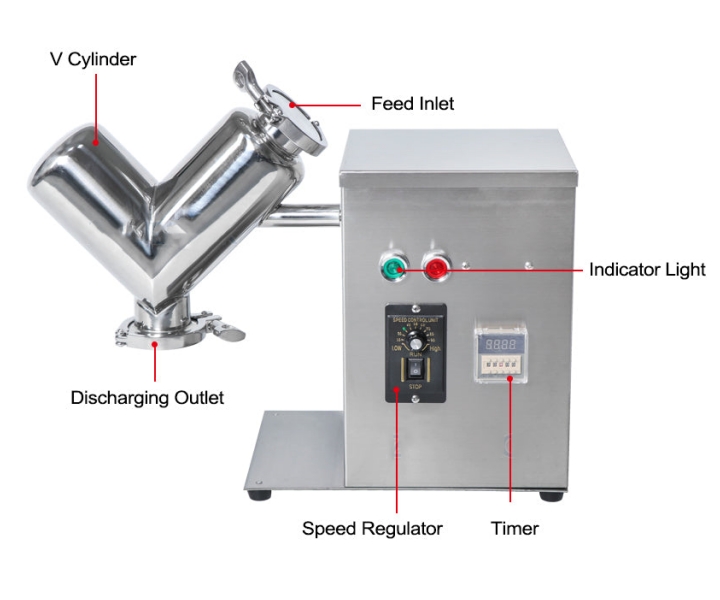

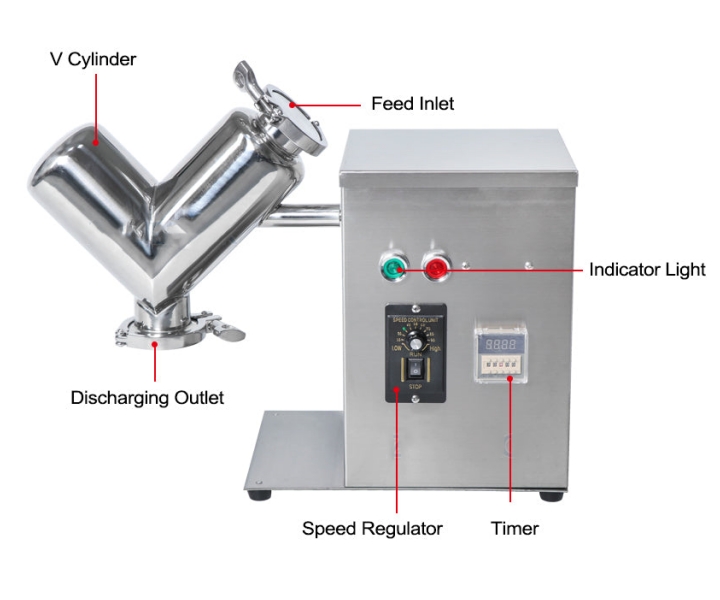

Main parameters:

Model: Different manufacturers have different model naming methods, which are usually related to the capacity and size of the mixer.

Capacity: The amount of material that the mixer can handle at one time, usually in liters or cubic meters.

Speed: The speed of the mixing drum affects the mixing time and effect.

Motor power: The motor power that drives the mixing drum to rotate is related to the capacity and speed of the mixer.

Material: The material of the mixing drum is usually stainless steel to meet the requirements of hygiene and corrosion resistance.

Tilt angle: The tilt angle of the V-type mixer affects the turning and mixing effect of the material.

Discharging method: There are many discharging methods such as manual and pneumatic.

Wide range of applications

It can be used to mix various powdered and granular feeds, such as grains, soybean meal, additives, etc. It can be flexibly adjusted according to different formulas to meet different feeding needs.

High mixing uniformity

The V-shaped structure allows the material to be fully turned during the mixing process, increasing the contact opportunities between the particles and making the mixing more uniform.

Short mixing time

The small rotary drum feed mixer has a fast speed, and the material turns quickly under the action of gravity, with a short mixing time, which improves production efficiency.

Small footprint

The small rotary drum feed mixer is compact and occupies a small area, making it suitable for small farms and pet food processing companies.

No dead angle design

The inner wall of the mixing drum is smooth and has no dead angles, which avoids material accumulation and ensures the mixing effect.

Economical price

The motor has low power, low energy consumption, saves costs, is relatively low in price, and has high cost performance.

In order to better meet the needs of different users, small rotary drum feed mixer manufacturers usually provide a variety of customized services. The following are some common customization types:

Single type: Multi-dimensional spatial movement makes the materials fully mixed and uniform on a macro scale. There is no centrifugal force and no dead corners during mixing. Large equipment over 1000 liters is not easy to make.

Double type: When the mixed powder has good fluidity and similar physical properties, a better mixing effect can be obtained, but there is a throwing action, which will destroy the shape of the powder.

Explosion-proof type: Suitable for flammable and explosive environments.

Dust removal type: Used to reduce dust pollution.

Material selection

Stainless steel: Stainless steel has the advantages of corrosion resistance and easy cleaning, and is suitable for the food and pharmaceutical industries that require high hygiene standards. Carbon steel: Carbon steel is economical and suitable for general industrial applications, but it needs to be treated with anti-rust.

Other special materials: Choose special materials such as wear-resistant and high-temperature resistant according to special requirements.

Model selection

According to capacity: Select a model with appropriate capacity according to production needs, which can be customized according to needs. General models include VH-2, VH-5, VH-8, VH-10, etc.

Control system

Manual control: Simple and easy to operate, suitable for simple production needs. PLC automatic control: Accurately control the mixing process, improve production efficiency, and is suitable for automated production lines.

Discharging system

Manual unloading: Simple operation, suitable for small-scale production. Pneumatic unloading: Fast, automated, and improves production efficiency. Hydraulic unloading: Suitable for viscous materials and can effectively empty the mixer.

Weight system

Weighing sensor: Accurately measure the weight of the mixed material to ensure the accuracy of the formula. Weighing control system: Real-time monitoring of the weight of the mixed material and automatic adjustment of the mixing process.

In farmers' domestic feedlots, small rotary drum feed mixers play a key role. By using this mixer, farmers can efficiently mix various feed ingredients to ensure the balance and consistency of the feed. They can easily operate the mixer and adjust the mixing time and speed as needed to meet the feed needs of different animals. This equipment takes up little space and is suitable for use in home farms.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.