In the construction industry, concrete is a common building material, and its quality directly affects the stability and durability of the building. In order to ensure the quality of concrete, the mixing process in concrete production is particularly important. Concrete for small mixer machine plays a key role as a piece of equipment specially designed for concrete production. Concrete for small mixer machine is a kind of equipment specially used for mixing concrete raw materials. Its main function is to uniformly mix cement, aggregate, water and other raw materials to ensure accurate concrete mix ratio and improve the uniformity and stability of concrete.

There are many types of small mixers. According to the use, function and design features, we sell the following mixers.

Vertical mixer: Often used for mixing decoration materials, such as mixing putty powder, tile adhesive, etc., to make wall treatment and tile paving more solid. The motor is powerful and occupies a small area.

Single-horizontal shaft mixer: It plays an important role in small construction sites, mixing concrete and mortar with excellent results, fast mixing speed, high efficiency, excellent quality, easy operation and long service life.

Twin-shaft mixer: Mainly used to mix powdered materials evenly, it is the key equipment for making standard bricks and other building materials.

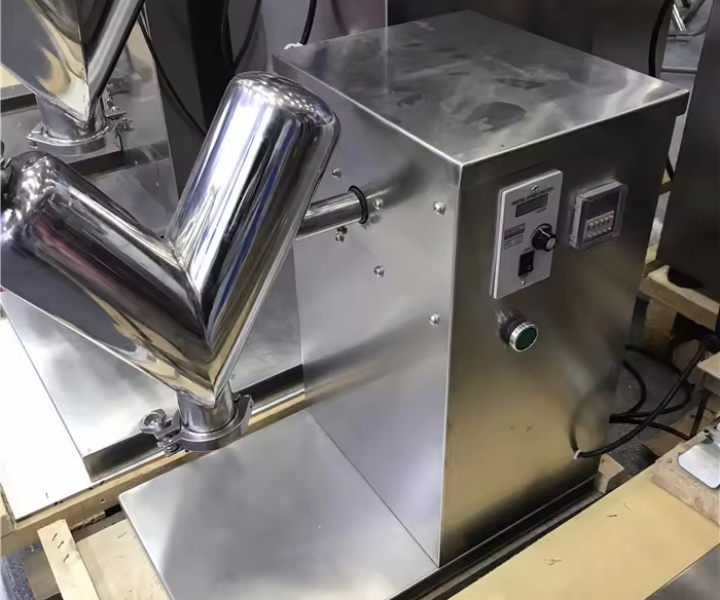

Concrete for small mixer machine uses a V-shaped groove design to put cement, aggregate, water and other raw materials into the groove. After starting the equipment, the mixer rotates to turn the raw materials over and mix. Due to the V-shaped groove design, the mixed materials continue to rise and fall during the mixing process, achieving full mixing. The high-speed rotation of the mixer makes the raw materials mix quickly and evenly, ensuring the accuracy of the concrete mix ratio and improving the uniformity and stability of the concrete. After mixing is completed, the mixed concrete raw materials can be taken out through the discharge port at the bottom of the equipment for subsequent production use.

V-shaped groove design: The V-shaped groove design allows the mixed materials to be fully turned over during the mixing process to achieve a more uniform mixing effect.

Wear-resistant material: Made of wear-resistant material, it can withstand high-intensity mixing of concrete raw materials and extend the service life of the equipment.

High efficiency and energy saving: High mixing efficiency, saving time and energy costs, and improving production efficiency.

Easy to operate: Easy to operate, easy to clean, and reduce labor costs.

Wide scope of application: Not only suitable for concrete production, but also for mixing other powder or granular materials.

Cost savings: The efficient mixing process saves time and energy costs, reducing production costs.

Concrete for small mixer machine is widely used in concrete production scenarios such as construction sites and concrete mixing stations. During the construction process, this equipment can quickly and efficiently achieve uniform mixing of concrete raw materials, ensure concrete quality, and improve project construction efficiency.

Small construction projects: In small construction projects such as rural self-built houses, small warehouse construction, and simple shed construction, small mixers can be used to mix concrete, cement mortar and other building materials.

Building maintenance and renovation: In building maintenance and renovation projects, such as wall repair, ground renovation, local structural reinforcement, etc., small mixers can easily mix the required repair materials.

Indoor decoration: In home decoration, small mixers can be used to mix putty powder, latex paint and other coatings to make the coatings evenly mixed and improve the coating effect and quality.

Garden construction: When creating courtyard landscapes, small mixers can be used to mix cement slurry for making rockery and sculptures, as well as concrete or sand and gravel mixtures for paving courtyard floors.

The concrete loading capacity of a small mixer usually ranges from tens of liters to hundreds of liters. The following specifications are common.

50 - 100 liters: Generally used in laboratories or small decoration projects, a small amount of concrete can be mixed each time, such as for making small concrete test blocks or repairing small building components.

150 - 350 liters: It is a relatively common small mixer specification, which can be used in some small construction scenes, such as the infrastructure construction of rural self-built houses, small landscape projects, etc., and can meet general concrete mixing needs.

400 - 600 liters: It is a relatively large small mixer with strong mixing capacity. It can be used in some slightly larger small construction projects. The amount of concrete mixed each time can meet the construction needs of a certain area or volume.

With the continuous development and technological advancement of the construction industry, concrete for small mixer machine will continue to play an important role. In the future, as the requirements for concrete quality continue to increase, concrete production equipment will become more intelligent and automated to meet market demand.

As a key equipment in concrete production, concrete for small mixer machine not only improves production efficiency and reduces production costs, but more importantly, ensures the quality of concrete and makes important contributions to the development of the construction industry. Our manufacturer produces many types of small mixers with favorable prices and guaranteed quality. If you want to know more, please click on our product page to view or contact us directly online.

The price range of small mixers is rich, which can meet the diverse needs of different consumers. The specific price also needs to be determined based on your mixing volume and mixed materials to determine the model for quotation. We have small mixers of different types and materials. If you need it, please feel free to contact us for a price list

Address:China,Yanjin county forest park gate to the west 1000 meters north road.