Widely used in feed production to achieve efficient mixing and uniform batching

![]()

![]()

Price:$900.00-$4,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 5-20min

One-time mixing: 100kg-6000kg(If it exceeds 6000kg, it can be customized according to needs)

Power: 13.5-75kw

Material: stainless steel,carbon steel

Application: It is widely used in the livestock breeding and feed processing industries and can be used to mix various feed ingredients, including powdered feed, pellet feed, concentrated feed, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Single shaft double screw feed mixer is a piece of equipment used for feed processing. It consists of a main shaft and two mutually spiral blades. Through the rotation of the main shaft, the double helix blades produce shearing, turning and folding movements in the mixing chamber to fully mix the feed ingredients. It has efficient mixing capacity and uniform mixing effect, can adapt to different types of feed raw materials, and improve feed quality and production efficiency.

The single shaft double screw feed mixer is characterized by its large mixing capacity and high-speed mixing effect, which can quickly and evenly mix various feed ingredients. It also has the advantages of simple structure, convenient operation and easy maintenance, and is suitable for farms and feed processing plants of various sizes. At the same time, its design also takes into account energy consumption and mixing uniformity during the mixing process to provide an efficient feed mixing solution.

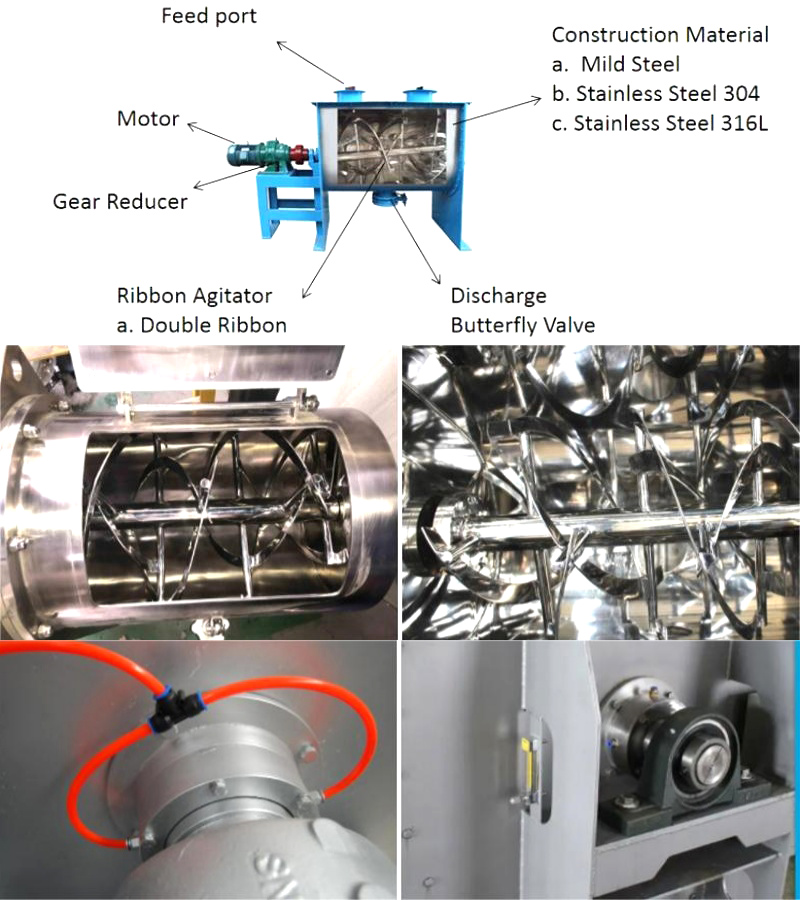

Common types of single shaft double screw feed mixers include vertical and horizontal types:

Vertical feed mixer: The main function of a ribbon mixer is to thoroughly mix and blend materials. The inner and outer helical ribbons rotate in opposite directions, creating a gentle and efficient mixing action. This ensures that the materials are uniformly distributed and blended, resulting in a homogeneous mixture.

Horizontal feed mixer: The main shaft of the vertical feed mixer is vertical, and the feed mixing chamber is at the upper part. This type of mixer is usually suitable for smaller feed production sites, takes up less space, and is easy to install and operate. Vertical mixers are generally suitable for small farms or household breeding.

In terms of materials, common materials for single-shaft twin-screw feed mixers are stainless steel and carbon steel:

Stainless steel material: Stainless steel is corrosion-resistant, easy to clean and maintain, and has a long service life. Stainless steel feed mixers are suitable for use in places where high hygiene standards are required, such as in the food processing industry.

Carbon steel material: Carbon steel material is relatively cheap and suitable for general feed production sites. Carbon steel feed mixers require regular anti-rust treatment and maintenance to extend their service life.

The choice of vertical or horizontal and stainless steel or carbon steel feed mixer usually depends on factors such as production scale, production requirements and budget. Choosing the right type and material based on specific needs can improve production efficiency and equipment durability.

Single shaft double screw feed mixer is widely used in the feed processing industry. It is an efficient mixing equipment that can evenly mix feed ingredients of different types and particle sizes. The application of this device is introduced in detail below.

Livestock breeding industry: Single shaft double screw feed mixer is widely used in livestock breeding industry to mix and prepare various animal feeds. It can evenly mix roughage, concentrated feed, additives and other raw materials to meet the nutritional needs of different animals.

Poultry breeding industry: In the poultry breeding industry, feed mixers are used to mix and prepare poultry feed, such as chicken feed, duck feed, turkey feed, etc. Mixing through a mixer can ensure the balanced distribution of various nutrients in poultry feed.

Aquaculture: Single shaft double screw feed mixer is also suitable for aquaculture. Feed for fish and other aquatic animals often consists of a variety of ingredients, including fishmeal, protein sources, plant materials, and more.

Pet food industry: In addition to livestock and poultry breeding industry, single shaft double screw feed mixer is also used in the pet food industry. It can be used to mix and prepare dog food, cat food and other pet food to ensure the balanced distribution of various nutrients in pet food.

The working principle of the single shaft double screw feed mixer is as follows:

Structural composition: The single shaft double screw feed mixer consists of a main shaft and two mutually spiral blades. The main shaft is driven by a motor, causing the blades to rotate around the main shaft.

Raw material feeding: Feed raw materials are added to the mixing chamber through the feeding port. Different feed ingredients and additives can be added as needed.

Mixing process: When the main shaft starts to rotate, the double helix blades start to rotate. The rotation of the blades produces shearing, turning and folding effects, so that the feed ingredients are continuously staggered and mixed in the mixing chamber.

Mixing effect: Due to the rotating motion of the blades, the feed ingredients are fully mixed in the mixing chamber, ensuring that various ingredients are evenly distributed. This improves the evenness and consistency of the feed and ensures that the animals receive a balanced feed.

Discharge: After mixing is completed, the mixed feed will be discharged through the discharge port. The discharge volume and speed can be controlled by adjusting the position and speed of the discharge port

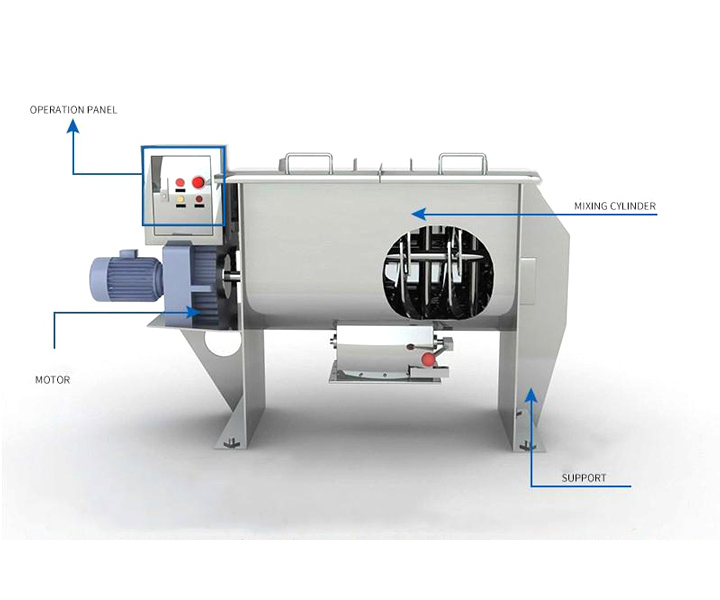

The structure of the single shaft double screw feed mixer is relatively simple and mainly consists of the following parts:

Mixing barrel: The mixing barrel is the main part of the entire equipment, usually made of steel plates, and the inside of the mixing barrel is cylindrical.

Spiral blades: The mixing barrel is equipped with two intersecting spiral blades that rotate along a single axis. Spiral blades are usually made of wear-resistant alloy materials.

Transmission system: The transmission system usually consists of a motor, a reducer and a coupling. It transmits the power of the motor to the spiral blades to realize the power drive of the mixing process.

Inlet and outlet: The inlet is usually located at the top of the mixing barrel, while the outlet is at the bottom, and the discharge of feed can be controlled by a switch.

Control system: The control system can be operated through the panel or buttons, allowing the operator to conveniently control the operation and parameter settings of the mixer.

Efficient and uniform mixing

Using a double helix structure, the spiral blades rotate along a single axis, making the mixing process more uniform and efficient.

Short mixing time

Due to the double-helix design, it can quickly and fully mix the raw materials, saving production time.

Simple and reliable structure

The structure is relatively simple and consists of a small number of key components, making operation and maintenance relatively convenient.

Adaptable

It can handle materials of different particle sizes and densities, and can be customized and adjusted according to customer needs.

Easy operation

The operator can operate through the control panel or buttons to adjust the mixing time and speed to achieve the desired mixing effect.

Energy saving

This equipment consumes less energy during the mixing process and can effectively save energy.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A breeding group is a large-scale livestock enterprise that faces the need to efficiently mix large amounts of feed ingredients. In order to improve production efficiency and feed quality, they chose a single shaft double screw feed mixer . Through the rotating motion of the double helix blades, the feed ingredients are fully staggered and mixed in the mixing chamber, achieving a highly uniform mixing effect. This enables breeding groups to quickly and efficiently mix large batches of feed, improves feed uniformity and quality, meets their needs for efficient mixed feed, and enhances the competitiveness of the overall breeding business.

Xinxiang Dahan single shaft double screw feed mixer manufacturer is a company specializing in the manufacturing of vibration equipment and one of the manufacturers of single shaft double screw feed mixer . The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The single shaft double screw feed mixer adopts high-quality materials and precision processing technology, with stable performance and long life. The product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan single shaft double screw feed mixer manufacturer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service, and is one of the trustworthy single shaft double screw feed mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.