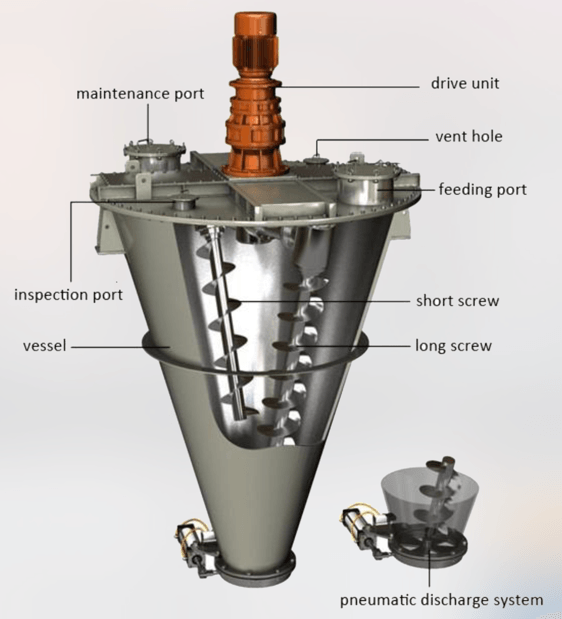

Single cone double screw mixers are commonly used mixing equipment, widely used in pharmaceutical, chemical, food and other industries. The advantages of single cone double screw mixers can be roughly divided into the following points: uniform mixing, good mixing effect, easy operation, and strong adaptability , no dead angle design and strong adjustability, etc. These advantages make single cone double screw mixers widely used in various industries, providing efficient and reliable solutions for material mixing in the production process.

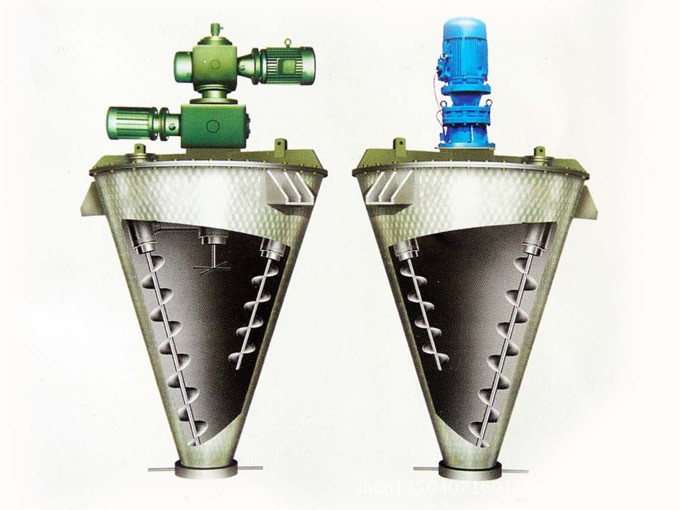

The Single cone double screw mixer adopts special structural design and mixing method, which can evenly mix materials of different particle sizes, densities and shapes. The agitator rotates in the conical container, causing the materials to continuously flip, fold and cross-move inside the container, thereby achieving uniform mixing of the materials.

The agitator of the single cone double screw mixer is reasonably designed to fully break and disperse the agglomeration of materials and avoid stratification and accumulation of materials. This ensures that the ingredients in each portion of the material are evenly distributed, improves the mixing effect, and reduces unevenness in subsequent processes.

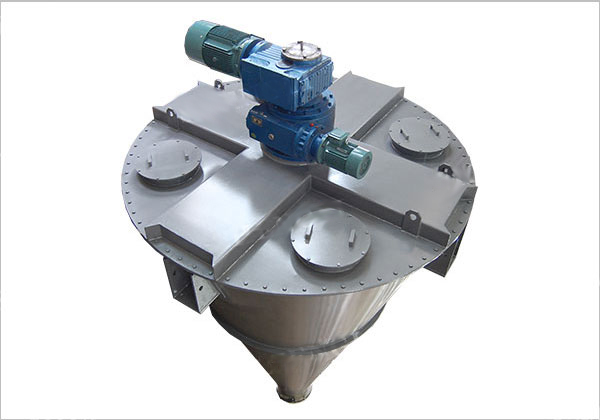

The operation of the single cone double screw mixer is relatively simple. You only need to put the materials into the container and start the mixer to start mixing. At the same time, the cleaning of the equipment is relatively easy. You only need to clean the container and agitator, which reduces the workload and time cost of the operator.

Single cone double screw mixers are suitable for mixing a variety of materials, including powders, granules, granules and powders, etc. It can handle a variety of different material properties, such as materials with large differences in particle size, density, humidity, etc., and has strong adaptability.

The internal design of the container of the single and double cone mixer fully considers the principle of no dead ends to ensure that there is no accumulation or residue of materials during the mixing process. This can avoid cross-contamination and degradation of material quality, and ensure the purity and quality of mixed materials.

The mixing speed and time of the single cone double screw mixer can be adjusted as needed to meet the mixing requirements of different materials. By adjusting the mixing parameters, different mixing degrees and times can be controlled to further improve the mixing effect.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.