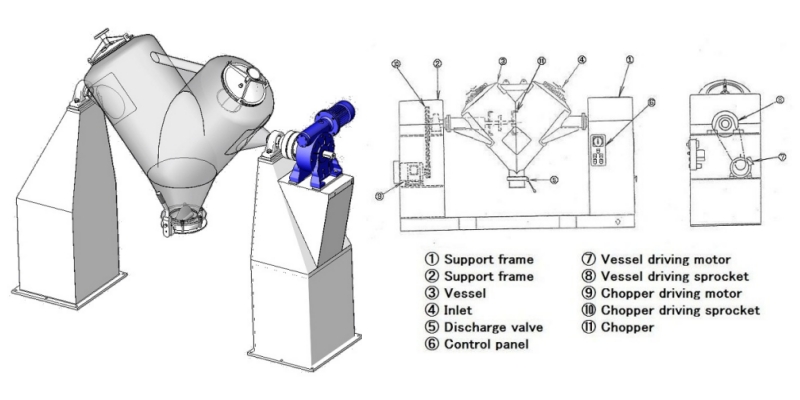

Rotary drum feed mixer is a kind of equipment specially used for mixing livestock and poultry feed. It consists of a rotating cylinder, a stirring device, a feed port, a discharge port, a transmission device and a motor. Through the rotating cylinder and internal stirring device, feeds with different ingredients are evenly mixed to ensure nutritional balance and stable quality of the feed.

Rotary drum feed mixers are widely used in the livestock and poultry feed production industry. It is suitable for mixing various livestock and poultry feeds, including granular feed, powdered feed and additives, etc. Whether it is a large farm or a small farmer, a rotary feed mixer can be used for feed mixing. It is widely used in the fields of poultry, cattle, pigs, sheep and other livestock and poultry breeding fields.

1. Uniform mixing: The rotating drum feed mixer can evenly mix feeds of different ingredients through the rotating cylinder and internal mixing device. The proportion of ingredients in each feed is the same to ensure balanced nutrition for livestock and poultry.

2. High efficiency and energy saving: The drum feed mixer adopts efficient motor and transmission device, which can complete the mixing process in a short time. At the same time, its energy consumption is relatively low, saving energy consumption.

3. Easy to operate: The rotating drum feed mixer has a simple structure, is easy to operate, and is easy to clean and maintain. It is usually equipped with an automated control system that enables precise control of the mixing process.

4. Wide adaptability: The rotary drum feed mixer is suitable for mixing different types and specifications of livestock and poultry feed. Whether it is granular feed or powdered feed, the mixing time and cylinder speed can be adjusted to meet different mixing requirements.

5. Improve feed quality: Through the mixing process of the rotary drum feed mixer, it can ensure that the various ingredients in livestock and poultry feed are fully mixed, reduce the stratification of ingredients, and improve the quality stability and balance of the feed.

6. Improve production efficiency: The rotating drum feed mixer has a large capacity and can meet the mixing needs of large quantities of feed. It can mix feed quickly and evenly, improve production efficiency and reduce production costs.

The working principle of the drum feed mixer is based on rotation and mixing. First, feed with different ingredients is put into the rotating drum through the feed port. Then, start the motor drive transmission device to cause the cylinder to start rotating. At the same time, the internal stirring device also starts to work, continuously rolling, stirring and mixing the feed. Under the action of rotation and stirring, the various ingredients in the feed are evenly mixed, ensuring that each feed contains the same proportion of ingredients. Finally, the mixed feed is discharged through the discharge port for subsequent packaging, storage or use.

For example, a large poultry farm uses a rotary feed mixer for feed preparation. They put different ingredients such as grains, beans, fish meal and additives into the drum mixer. After a period of rotation and stirring, the feed is evenly mixed. This mixing method ensures full mixing of various ingredients in the feed and improves the nutritional balance and quality stability of the feed. By using a rotary drum feed mixer, the farm has improved the quality of feed and promoted the growth, development and health of the poultry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.