Achieve efficient and uniform material mixing through tilted mixer and container design

![]()

![]()

Price:$10,000.00-$50,000.00/Set

Consult now and enjoy a 10% discount

Mixing Power: 150+37+3KW

Charging Capacity: 1000L

Speed of Mixing Drum: 150rpm

Working Cycle Period: 3MINS

Discharge Way: automatic

Application industries:Medicine industry, cosmetics industry, food industry, building materials industry, metallurgy industry, chemical industry, environmental protection, etc.

Mixing ingredients:Powders, granules, pigments, plastic particles, drugs, chemical raw materials, grain, feed additives, concentrated feed, mortar, food ingredients, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

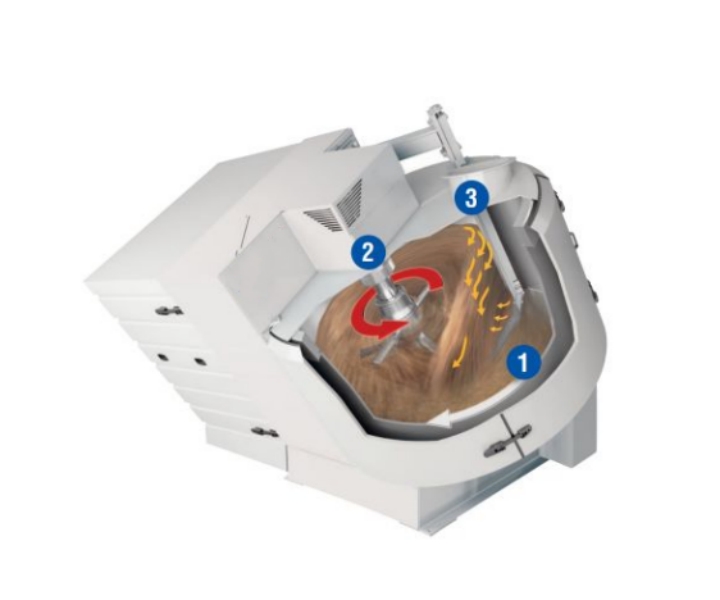

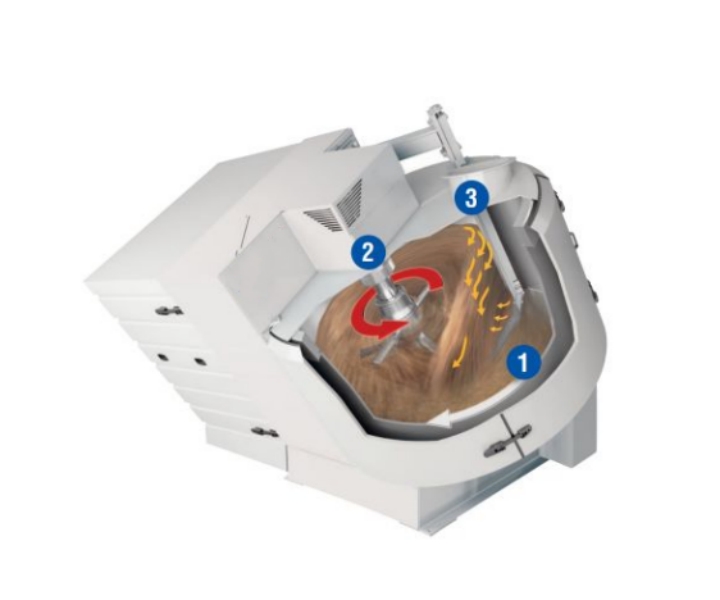

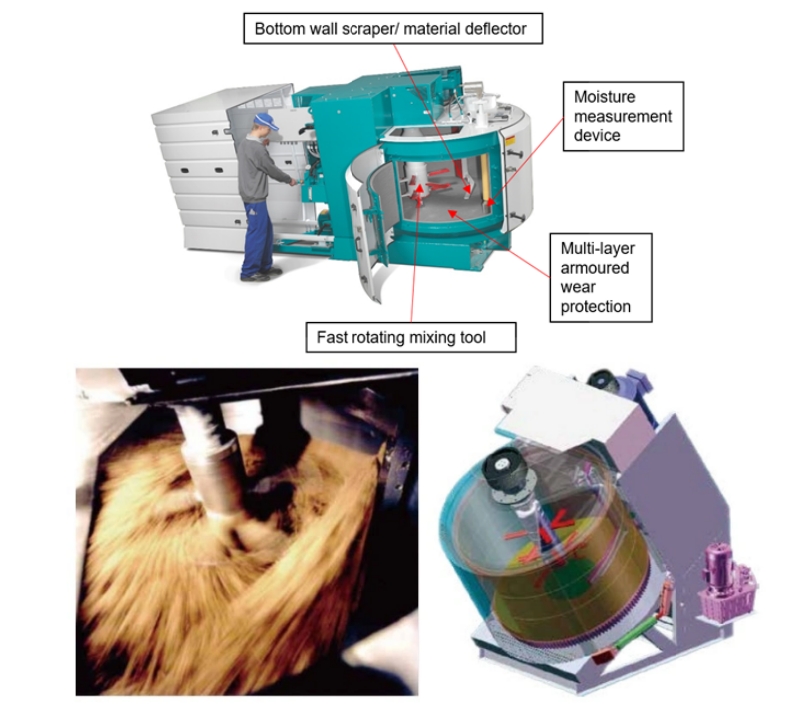

Inclined Intensive Mixer is a professional mixing equipment that achieves efficient mixing of materials through the design of the inclined mixer and container. The equipment uses powerful stirring and tilting motion to fully mix different types of materials to achieve a uniformly dispersed state. The inclined design makes the mixing process more thorough, mixing materials together quickly and evenly, thereby improving product quality and stability.

The inclined intensive mixer has several advantages. First, it can complete the mixing process in a short time and improve production efficiency. Secondly, the inclined design allows the materials to be fully turned and mixed in the container to ensure uniformity and consistency of mixing. In addition, this equipment also has the characteristics of simple structure, convenient operation, easy cleaning and maintenance, etc., and is suitable for various fields, such as food, pharmaceutical, chemical industry, etc. The application of inclined intensive mixer can help companies improve product quality, improve production efficiency, and meet the mixing needs of different industries.

Single-shaft inclined intensive mixer

A single-shaft inclined intensive mixer is a common type that has a single inclined mixing barrel and an internal stirring device, and the mixing effect is achieved through the rotation of a single shaft.

Dual-shaft inclined intensive mixer

The dual-shaft inclined intensive mixer adds a second mixing shaft to the single-shaft mixer, which can improve the mixing effect and speed and is suitable for occasions that require more thorough mixing.

Vertical inclined intensive mixer

The mixing barrel of the vertical tilting intensive mixer is placed vertically, and the internal stirring device moves in the vertical direction. It is suitable for some special mixing requirements and occasions with limited space.

Inclined intensive mixers have a wide range of applications in multiple industries. Here are some common uses for inclined intensive mixers:

Food industry:Inclined intensive mixer can be used for mixing food additives, such as seasonings, spices, pigments, etc., for uniform dispersion. It can ensure the complete mixing of food additives and improve the quality and stability of food.

Pharmaceutical industry: In the pharmaceutical process, inclined intensive mixers can be used to mix pharmaceutical ingredients, formulas and powders. It can quickly and evenly mix different pharmaceutical ingredients together to ensure the uniformity and consistency of the medicine.

Chemical industry: Inclined intensive mixers are widely used in the chemical industry to mix different chemical substances, liquids and powders. It is able to effectively mix different ingredients together to meet the needs of chemical production processes.

Building materials industry: In building materials production, inclined intensive mixers can be used to mix cement, gypsum, pigments and other materials to prepare concrete, mortar, paint and other building materials. It can ensure the uniform dispersion of various ingredients in building materials and improve the quality and performance of products.

The working principle of the inclined intensive mixer is based on the design of the inclined container and mixer. The following is a brief description of how the inclined intensive mixer works:

Inclined container: The container of an inclined intensive mixer is designed to have an inclined shape, usually in a tapered or V-shape. This design makes the material tend to flow freely in the container, which is conducive to stirring and turning during the mixing process.

Mixer: An inclined intensive mixer is equipped with a powerful mixer, usually with a blade or spiral. The agitator pushes the material to the upper part of the container by rotating and tilting the container at an inclination angle, and pours it back to the bottom of the container. This stirring and pouring action allows the materials to be thoroughly mixed.

Mixing process:During the working process, the inclined intensive mixer first puts the materials to be mixed into an inclined container. The mixer then begins to rotate, pushing the material to the upper part of the container and dumping it back to the bottom of the container. This process is repeated until the desired mixing effect is achieved.

Mixing effect: The stirring and pouring actions of the inclined intensive mixer enable the materials to be fully turned and mixed in the container. This mixing method can mix different types of materials together quickly and evenly, ensuring uniformity and consistency of mixing.

Efficient mixing

The inclined intensive mixer achieves rapid and even mixing of materials through the rotation of the mixer and the tilt angle of the tilted container. It can quickly mix different types of materials together and improve mixing efficiency.

Uniformity

The stirring and pouring actions of the inclined intensive mixer can fully turn and mix the materials to ensure uniform mixing. It can evenly disperse materials of different particle sizes, densities and shapes to avoid local aggregation or stratification.

Simple structure

The structure of the inclined intensive mixer is relatively simple, consisting of a tilted container and a stirrer. It has no complicated transmission devices or additional parts, and is relatively easy to operate and maintain.

Easy to operate

The operation of the inclined intensive mixer is relatively simple. Just put the materials into the container and start the mixer to start the mixing process. The operator can adjust the stirring speed and mixing time as needed to meet different mixing requirements.

Easy cleaning and maintenance

Due to the simple structure of the inclined intensive mixer, cleaning and maintenance are relatively easy. Operators can easily clean containers and mixers to avoid cross-contamination between different materials.

Applicable to multiple industries

Inclined intensive mixer is suitable for multiple industries, including food, pharmaceuticals, chemicals, building materials, etc. It can meet the mixing needs of different industries and improve production efficiency and product quality.

| Model | VOLUME(L) | WEIGHT(KG) | Discharging Way |

| R02 | 1-6 | 5-8 | Electric Lift, Manual Discharge |

| R03 | 5-8 | 8-10 | Pan Inclines To Discharge |

| R05 | 40-50 | 50-60 | Pan Inclines To Discharge/Hydraulic Central Discharge |

| R09 | 110-150 | 120-180 | Hydraulic Central Discharge |

| R11 | 200-300 | 300-450 | Hydraulic Central Discharge |

| R15 | 500-750 | 750-1000 | Hydraulic Central Discharge |

| R19 | 1000-1500 | 1000-1800 | Hydraulic Central Discharge |

| R22 | 2000-2500 | 2000-2600 | Hydraulic Central Discharge |

| R24 | 2500-3000 | 3000-3500 | Hydraulic Central Discharge |

A food manufacturing company needs to mix a variety of dry powder raw materials during the production process to prepare food products with specific formulas. They chose the inclined intensive mixer as their mixing equipment. This inclined intensive mixer has the advantages of efficient mixing and uniformity, and can quickly and thoroughly mix different types of dry powder raw materials together. By adjusting the mixing speed and mixing time, they are able to perform precise mixing operations based on the formulation requirements of different products. In addition, the inclined intensive mixer has a simple structure, is easy to operate, and is relatively easy to clean and maintain, which brings convenience to their production process.

Xinxiang Dahan inclined intensive mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the inclined intensive mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The inclined intensive mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan inclined intensive mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy inclined intensive mixer manufacturers

Address:China,Yanjin county forest park gate to the west 1000 meters north road.