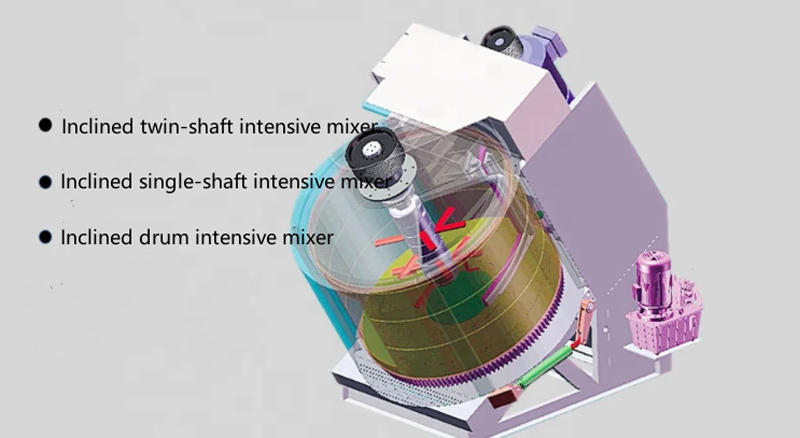

Inclined Intensive Mixer is a common mixing equipment, which can be divided into the following types according to different structures and working principles:

Inclined twin-shaft intensive mixer: This mixer has two inclined mixing shafts with mixing blades or mixing arms mounted on them. Through the relative movement of the two shafts, the feed ingredients can be sheared, turned and mixed during the mixing process to achieve a uniform mixing effect. The inclined twin-shaft intensive mixer is suitable for mixing powdery, granular and fibrous materials and is widely used in chemical, metallurgy, building materials and other industries.

Inclined single-shaft intensive mixer: This type of mixer has only one inclined mixing shaft with mixing blades or mixing arms installed on the shaft. Through the rotation of the shaft and the design of the mixing device, the feed ingredients can be stirred, turned and mixed during the mixing process to achieve a uniform mixing effect. Inclined single-shaft powerful mixer is suitable for mixing powdery and granular materials and is commonly used in pharmaceutical, chemical, food and other industries.

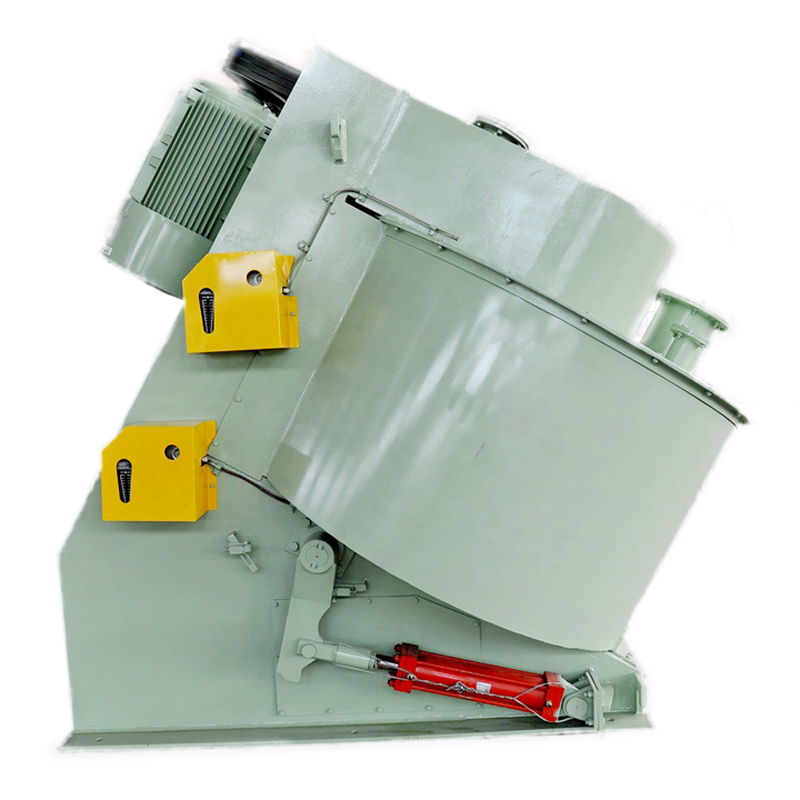

Inclined drum intensive mixer: This mixer adopts an inclined drum structure with mixing blades or mixing arms installed inside the drum. Through the rotation of the drum and the design of the mixing device, the feed ingredients can roll, flip and mix within the drum to achieve a uniform mixing effect. The inclined drum intensive mixer is suitable for mixing granular and fibrous materials and is commonly used in metallurgy, chemical industry, building materials and other industries.

These different types of inclined intensive mixers differ in structure and working principle, but their common feature is the ability to achieve efficient mixing effects and ensure the uniformity and consistency of materials. Selecting the appropriate type depends on specific application requirements and material characteristics.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.