Horizontal concrete mixer is an important piece of equipment in the construction industry. It uses a horizontal mixing shaft and agitator to evenly mix cement, aggregate, water and other raw materials to ensure stable concrete quality. This equipment offers the advantages of efficient production, uniform mixing, versatility, reliability and cost savings. With the development of the construction industry and the advancement of technology, horizontal concrete mixers will continue to play an important role in promoting the development of the construction industry in a more efficient and reliable direction. Its advantages allow it to play a key role in concrete production. The advantages of horizontal concrete mixers will be introduced in detail below.

Uniform mixing: The horizontal concrete mixer can achieve uniform mixing of raw materials and ensure stable concrete quality. Through the horizontally placed stirring shaft and stirrer, various raw materials can be fully mixed to avoid the problem of insufficient uniformity.

Efficient production: This equipment has high production efficiency and can produce concrete quickly and in large quantities to improve project progress. Its fast and effective mixing process can meet the project's demand for concrete supply and improve production efficiency.

Versatility: Horizontal concrete mixers are versatile and can be adjusted according to different concrete proportion requirements to meet the needs of various engineering projects. Whether it is ordinary concrete or special concrete, it can be produced by adjusting equipment parameters.

Reliability: The equipment operates stably and reliably, ensuring the continuity and stability of concrete production and reducing project risks. Horizontal concrete mixers are carefully designed and manufactured to have high reliability and can operate stably for a long time.

Cost savings: Using a horizontal concrete mixer to produce concrete can save manpower, time and costs, and improve production efficiency and economic benefits. Compared with traditional manual mixing methods, concrete mixers can complete concrete production tasks faster and more efficiently.

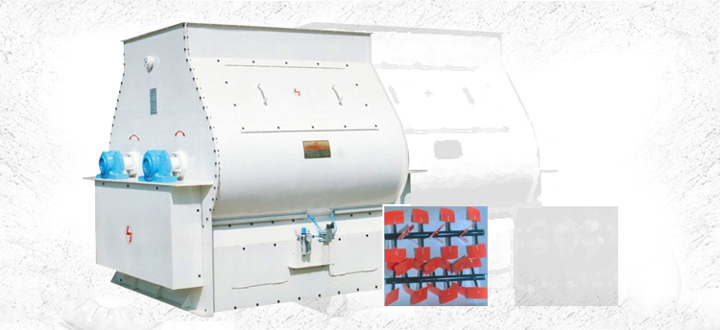

Horizontal mixing: The horizontal concrete mixer uses a horizontally placed mixing shaft and agitator to achieve horizontal mixing of raw materials. This mixing method can ensure that the raw materials are fully mixed and avoid the problem of uneven concrete quality.

Forced mixing: Horizontal concrete mixers usually use forced mixing to ensure that the concrete raw materials can be fully mixed. Forced mixing can improve the uniformity and consistency of concrete and ensure concrete quality.

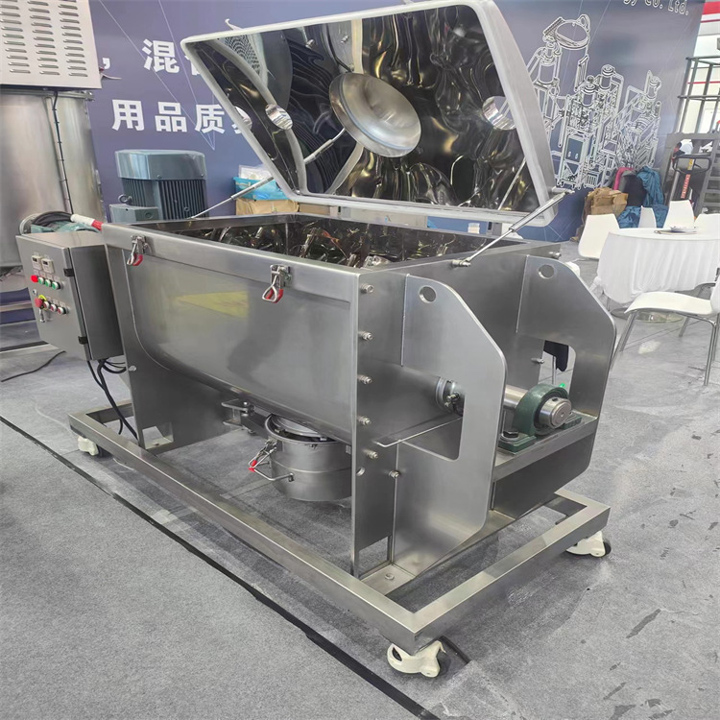

Mobility: Some horizontal concrete mixers are mobile and suitable for projects that require frequent relocation. This mobility allows the equipment to flexibly respond to the needs of different engineering projects and improve production efficiency.

Automation: Some horizontal concrete mixers have automation functions, which can realize automatic mixing, metering and control, improve production efficiency and reduce labor costs. Automation functions make equipment more intelligent and convenient.

Horizontal concrete mixers have become one of the indispensable equipment in the construction industry due to their advantages of uniform mixing, efficient production, versatility, reliability and cost saving, as well as features such as horizontal mixing, forced mixing, mobility and automation. . In the future, with the development and technological advancement of the construction industry, horizontal concrete mixers will continue to play an important role in providing high-quality concrete materials for various engineering projects and promoting the development and progress of the construction industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.