Double Shaft Paddle Feed Mixer for Solids and Powders is an industrial device designed for high-speed mixing of solid particles and powders. Its dual, counter-rotating paddles achieve uniform blending of materials of varying shapes and densities through forced convection, shearing, and dispersion. Its most significant advantage lies in its highly customizable capabilities. The Double Shaft Paddle Feed Mixer inlet and outlet can be flexibly adjusted to meet diverse factory layouts and production line integration requirements. Whether it's top-side feed, bottom-angle feed, or straight or side-angled discharge, the optimized structure allows for precise adaptation, completely breaking the installation limitations of standard equipment. Furthermore, universal wheels can be added as needed, allowing the device to be repositioned to mix other products after use. This balance of performance and customization makes it an ideal choice for solving a variety of complex mixing needs.

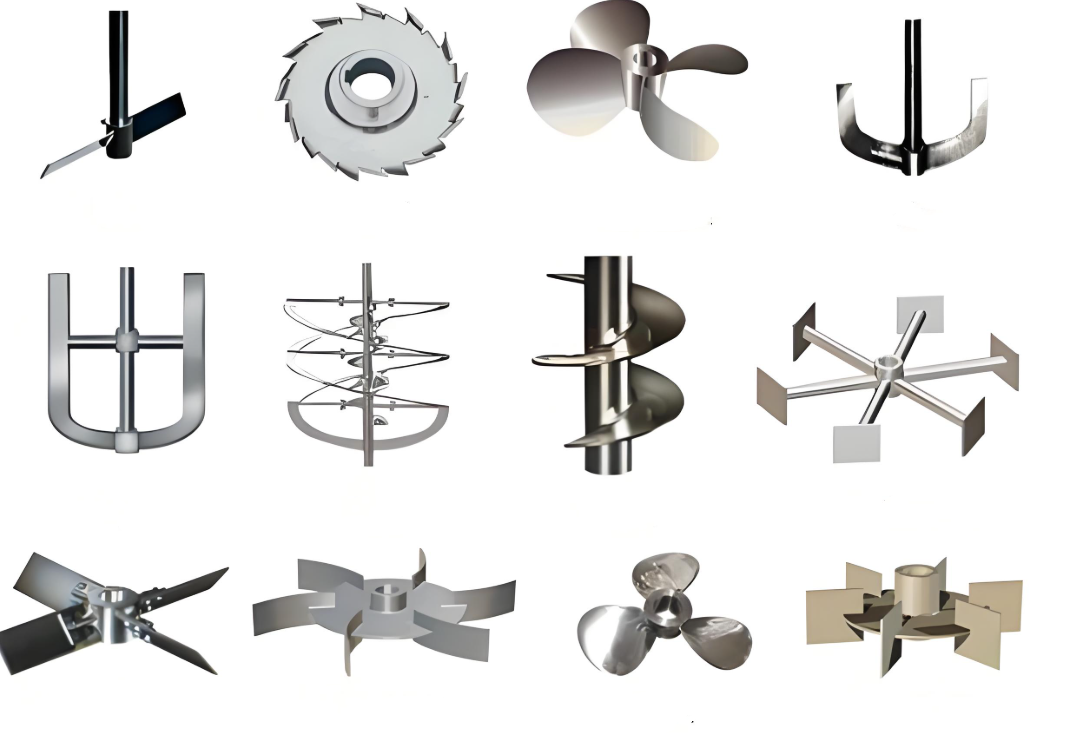

Based on customer needs, we offer Double Shaft Paddle Feed Mixers for Solids and Powders with a variety of impeller types, including turbine, paddle, anchor, and ribbon. These impellers can meet process requirements such as high-viscosity shearing, fine powder anti-agglomeration, and rapid homogenization.

Paddle impellers:Typically equipped with two blades, these impellers are secured to the hub by welding or bolting. Available in straight and folding blade configurations. Their design makes them suitable for low-speed mixing operations, particularly for mixing low-viscosity materials.

Turbine impellers:Characterized by multiple blades and high speeds, they come in two configurations: open turbine and disc turbine. The former has blades directly mounted to the hub, while the latter is indirectly secured via a disc. These impellers generate strong shear forces and are suitable for mixing and dispersing low- to medium-viscosity liquids, as well as for gas-liquid mixing, effectively improving mass transfer efficiency.

Anchor-type impellers:Designed to fit snugly against the reactor wall, with minimal clearance, some models feature scrapers, effectively preventing the buildup of high-viscosity materials and promoting heat transfer. They are commonly used in polymerization reactions and other applications.

Spiral-type impellers:Utilizing double-helical ribbon-shaped blades that rotate along the reactor wall, they are suitable for full-scale mixing of extremely high-viscosity materials such as pastes and colloids. Despite their limited speed and complex structure, they are an irreplaceable solution for high-viscosity applications.

As a leading equipment in the industrial mixing field, the Double Shaft Paddle Feed Mixer for Solids and Powders has become a preferred choice for industries such as food, pharmaceuticals, and chemicals due to its outstanding performance in throughput, adaptability, efficiency, residue control, and customization.

Large Capacity: The equipment can achieve a single batch throughput of 0.5-10 tons, driven by its optimized horizontal cylinder structure and powerful power system. Its large-diameter cylinder design allows for flexible customization of the volume from 500L to 10,000L, depending on the required throughput. Wide Range of Applications: The equipment can handle a wide range of solid particles and powders, from irregular solid particles with a particle size of 0.1mm-50mm to ultrafine powders with a fineness of several hundred mesh.

Short Mixing Time: Efficient fusion is achieved in 3-10 minutes. The key to this improved mixing efficiency lies in the forced convection design of the dual-shaft impellers. Two sets of counter-rotating impellers are arranged in a staggered pattern, creating a three-dimensional mixing flow field characterized by radial turbulence, axial conveying, and shear dispersion. This achieves 99% uniformity in just 3-5 minutes.

High Customizability: The equipment's high customizability is reflected in the flexible selection of materials, configurations, and functions. In addition to standard 304 stainless steel, materials such as acid- and alkali-resistant 316L stainless steel and wear-resistant manganese steel can be selected as needed. The feed system offers various configurations, including vacuum suction and spiral feeding. The discharge system can be equipped with a screening device or automatic weighing module. Temperature monitoring, humidity control, and CIP online cleaning are also available.

The Double Shaft Paddle Feed Mixer for Solids and Powders is designed with high-speed mixing and stable feeding in mind. Its main body is a horizontal cylindrical drum, typically constructed of 304 or 316 stainless steel. It withstands chemical corrosion from a wide range of materials and is easy to clean and maintain, meeting the hygiene and safety requirements of various industries.

Wide-opening discharge valve: The valve is flush with the drum's inner wall, and the discharge port can be fully opened to the drum edge. The arc-shaped valve design ensures that no dead corners are left for material accumulation.

Two-piece detachable structure: Replaceable small blades are provided on the base. When worn, only partial component replacement is required, reducing maintenance costs by 60%.

Direct-connected gear reducer: Torque is increased by 40%, and maintenance is reduced by 75%. The intelligent control system monitors parameters such as paddle speed and material moisture in real time, automatically adjusting mixing time and water addition ratio.

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

The Double Shaft Paddle Feed Mixer for Solids and Powders utilizes a dual mixing principle of "forced convection + shear dispersion." When the device is started, the two shafts rotate at a constant speed in opposite directions, driving the paddles to exert strong thrust and shear forces on the solids and powders entering the mixing drum.

Radial Turbulence: The rotating paddles push the material radially to the sides of the cylinder, allowing the material to rapidly exchange positions horizontally.

Axial Conveying: The inclined paddles simultaneously drive the material in a back-and-forth motion axially, creating a circulating flow.

Shear Dispersion: The cross-paddles tear and break up agglomerated powders or solid particles, breaking down the stratification caused by density and particle size differences.

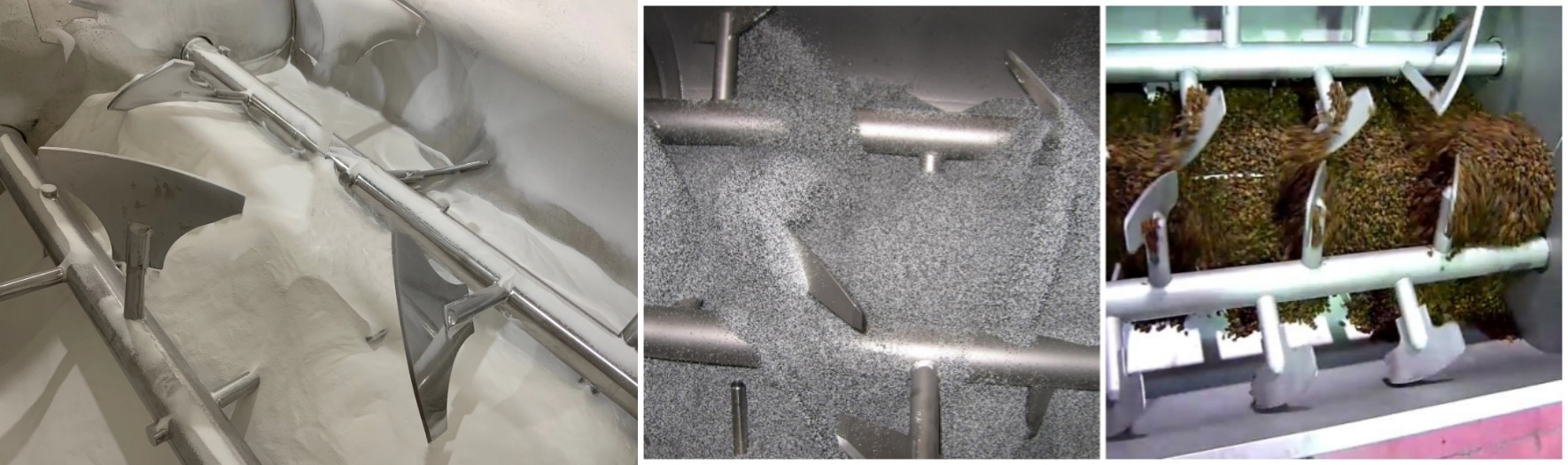

The Double Shaft Paddle Feed Mixer for Solids and Powders, with its high-speed mixing, low residue, and wide adaptability, is widely applicable in a variety of material mixing scenarios.

Basic Powder Materials: Double Shaft Paddle Feed Mixers for Solids and Powders are widely used in the basic powder field, covering the two core industries of construction and building materials and chemicals. In the construction and building materials sector, they can efficiently mix cement-based materials, sand and gravel aggregates, and insulation materials for the production of concrete, dry-mix mortar, and insulation boards. They also support uniform mixing of decorative materials, ensuring stable product performance.

Solid-Liquid Mixing and Special Rheological Materials: Through its innovative design, this equipment breaks through the boundaries of solid-liquid mixing and can handle low-moisture wet materials and high-viscosity suspensions. In low-water content applications, spray dosing technology ensures uniform coating of concrete admixtures, food additives, feed enzymes, and other materials within the powder, ensuring precise content. For high-viscosity materials, some models are equipped with high-speed crushing rods or double-layered paddles to effectively break up aggregates and maintain flow stability.

Customized solutions for special functional materials: For high-risk and demanding materials, the equipment provides targeted safety and performance assurance. Flammable and explosive materials are protected with nitrogen shielding or explosion-proof motors to mitigate risks. Corrosive powders are constructed of 316L stainless steel to extend equipment life. Ultrafine powders utilize variable frequency drive to reduce shear stress and prevent nanoparticle agglomeration. For heat-sensitive materials, a jacket cooling system maintains a temperature of ≤60°C to protect active ingredients.

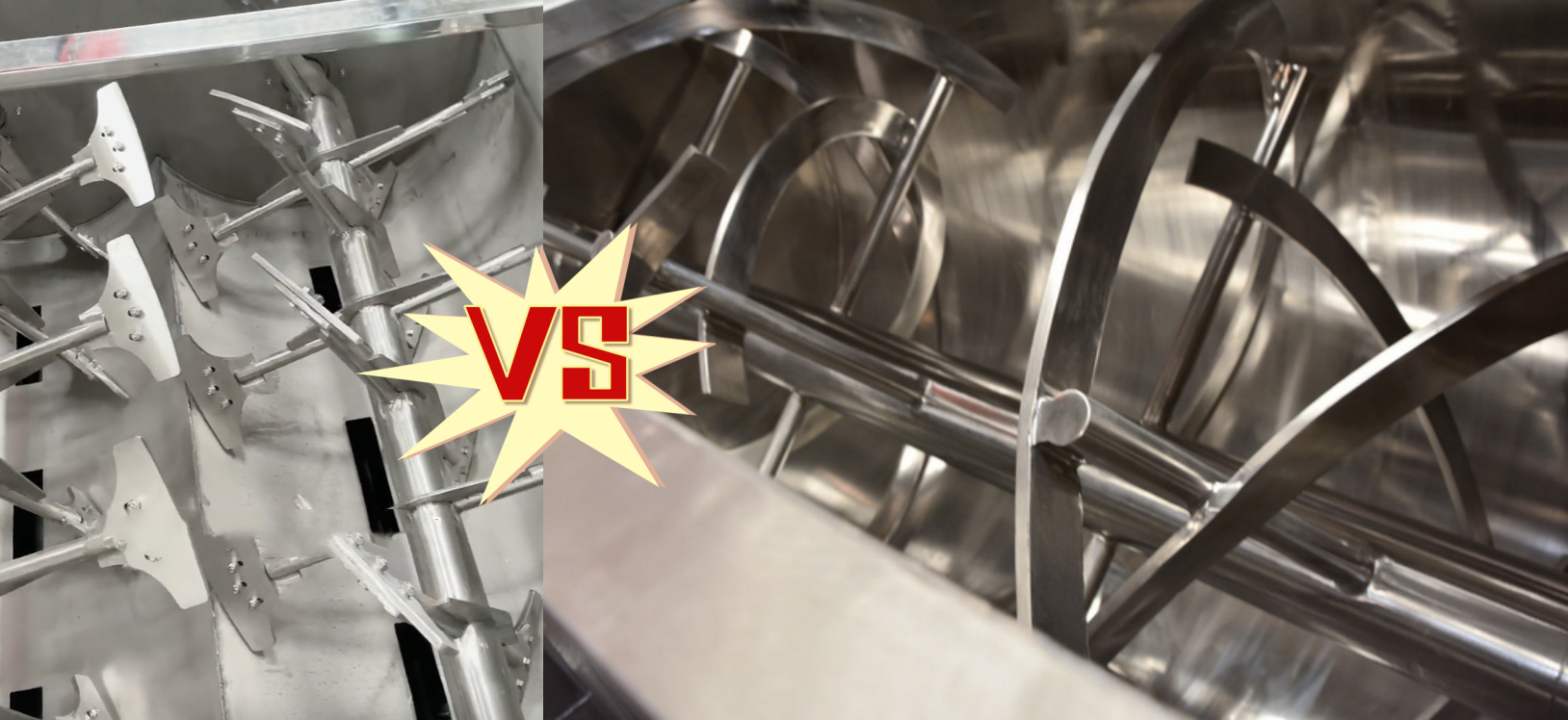

Dual-shaft mixers offer more uniform mixing and 50% higher efficiency, making them suitable for challenging materials. Single-shaft mixers are economical and practical, suitable for general mixing, and require a lower investment cost.

Dual-shaft paddle mixers: Using two counter-rotating shafts and specially designed paddles, they achieve three-dimensional mixing, significantly improving mixing uniformity and efficiency. Their complex structure offers strong adaptability, allowing them to handle low- to medium-viscosity materials, while utilizing liquid injection or countercurrent designs to meet complex process requirements such as solid-liquid mixing and extended mixing times. They are suitable for industries requiring high mixing precision, such as food, pharmaceuticals, and chemicals, as well as for applications requiring efficient handling of high-viscosity or multi-functional mixing.

Single-shaft paddle mixers: A single rotating shaft drives the paddles, achieving mixing through unidirectional flow. They feature a simple structure, low energy consumption, and high continuous operation capability. While their mixing uniformity is limited by unidirectional flow, they are more suitable for low-viscosity materials and applications with stable process parameters. Their advantages include low cost and ease of operation, making them suitable for large-scale production applications with low mixing precision or limited budgets.

As a leading manufacturer of mixing equipment, we support customized production and offer the right Double Shaft Paddle Feed Mixer for Solids and Powders for different customer needs. The following are examples of user experiences in various industries.

In the new energy materials industry, uniform mixing of various metal oxide powders and additives is required. Traditional single-shaft mixers are prone to agglomeration and uneven particle size distribution. By introducing a customized double-shaft paddle mixer with a countercurrent impeller design and a wear-resistant ceramic coating, enhanced powder shear dispersion is achieved. Equipped with an online particle size detector, this mixer shortens mixing time and improves product volume consistency.

In the mixing of compound seasoning powders, traditional equipment faces challenges such as severe residue, high risk of cross-contamination, and low manual feeding efficiency. A fully enclosed twin-shaft paddle mixer with an integrated vacuum feeding system and CIP cleaning-in-place functionality, combined with food-grade 304 stainless steel paddles, achieves automated dust-free feeding and seamless cleaning.

Fly ash modification and mixing: This requires mixing with auxiliary materials such as lime and gypsum, but traditional equipment is prone to blockage and high energy consumption. A customized twin-shaft paddle mixer with a variable-diameter blade design enhances axial propulsion and prevents fine powder agglomeration. An integrated waste heat recovery device utilizes frictional heat to preheat the raw materials, reducing heating energy consumption. The modified equipment operates continuously without blockage, achieving a mixing uniformity CV value of ≤3%, and a modified fly ash activity index of 92%.

Our Double Shaft Paddle Feed Mixer for Solids and Powders focuses on fast mixing, durability, and energy efficiency. It features a proprietary countercurrent impeller design, wear-resistant coating, and intelligent control system. Our products are used in over 20 industries, including new energy materials, food, and building materials, serving over 500 customers worldwide. We are ISO 9001 certified and provide a full lifecycle service, from equipment customization and delivery to after-sales maintenance. We can tailor-make the right mixing equipment to meet the mixing needs of various industries.

With its precise structural design and high-speed mixing principle, the Double Shaft Paddle Feed Mixer for Solids and Powders perfectly solves the mixing challenges of solids and powders of varying forms, providing strong support for standardized industrial production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.