Conical twin screw mixer is a common industrial mixing equipment. It uses the rotational motion of the twin screw mixer in the conical container to effectively turn and stir the materials to achieve uniform mixing. When the mixer rotates, the material is quickly pushed to the top of the container and descends along the wall to form a screw motion, causing the material to move in multiple directions to ensure uniform mixing. This design is suitable for chemical, pharmaceutical, food and other fields to mix chemical raw materials, pharmaceutical raw materials, food ingredients, etc. The working principle and workflow of the conical twin screw mixer will be introduced in detail below.

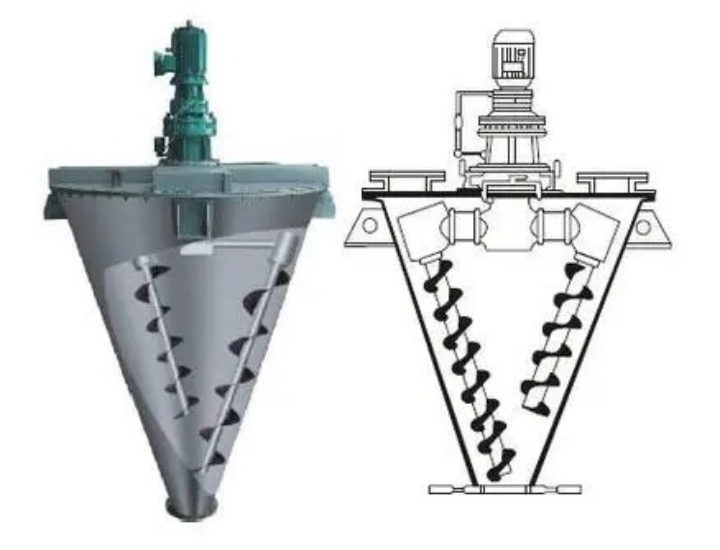

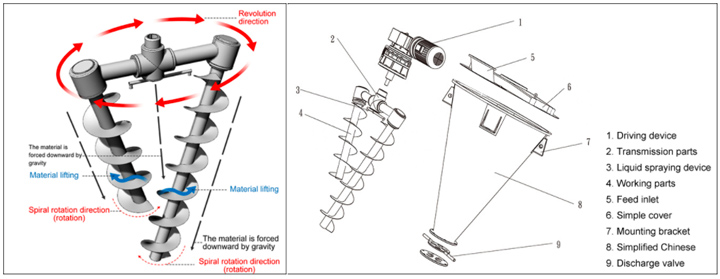

Structural composition: The conical twin screw mixer is mainly composed of a conical container, a twin screw agitator, and a transmission system. The twin screw agitator is located inside the container and is driven by a transmission system to rotate the agitator within the container.

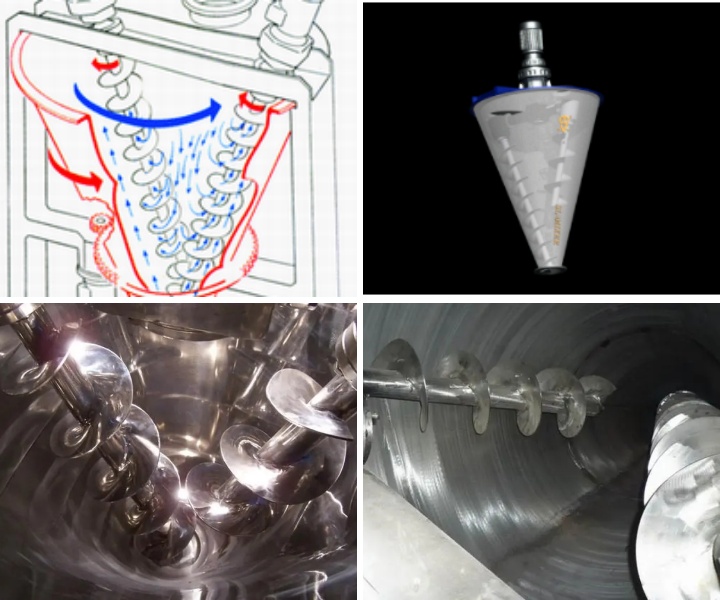

Agitator function: The design of the twin screw agitator enables it to effectively turn and stir the materials in the container. When the mixer rotates, the material is quickly pushed to the upper part of the container and then drops along the wall, forming a spiral motion. This movement mode allows the materials to be fully mixed in the container, thereby achieving a uniform mixing effect.

Mixing process: During the mixing process, the twin screw agitator not only causes the material to move up, down, left and right in the container, but also causes the material to rotate in the container. This combination of multi-directional movements allows the materials to be fully stirred and mixed throughout the mixing process, ensuring uniform mixing.

Mixing effect: Due to the design and movement of the twin screw mixer, the conical twin screw mixer can effectively mix materials with different particle sizes, densities and shapes, avoid stratification or uneven mixing, and ensure the consistency of the mixed materials. Uniformity and stability.

Loading: First, put the materials to be mixed into the conical container according to the formula requirements.

Start the equipment: Start the transmission system of the conical twin screw mixer to make the twin screw mixer start to rotate.

Mixing process: The rotation of the twin screw agitator causes the material to undergo complex movements in the container, including up and down, left and right, and rotational movements, thereby achieving the mixing effect.

Monitor mixing: During the mixing process, the mixing effect can be monitored by observing the working status of the mixer and the status of the mixed materials to ensure uniform mixing.

Stop the equipment: When the mixing reaches the required uniformity, stop the operation of the mixer and take out the mixed materials.

Clean the equipment: Clean the mixer and make sure the equipment is clean for next use.

Efficient and uniform: The conical twin screw mixer can mix various materials efficiently and evenly through the complex motion of the twin screw mixer to ensure the consistency and stability of the mixing.

Wide applicability: Due to its excellent mixing effect, the conical twin screw mixer is widely used in chemical, pharmaceutical, food and other industries to meet the needs of different industries for mixing effects.

Easy operation: It is relatively simple to operate the conical twin screw mixer. You only need to follow the operating process to achieve efficient mixing.

Energy Saving: Because the design and movement of the twin screw agitator can effectively utilize kinetic energy during the mixing process, the conical twin screw mixer is relatively energy-saving.

The conical twin screw mixer has become one of the indispensable and important equipment in industrial production due to its efficient and uniform mixing effect, providing reliable mixing solutions for production in various industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.