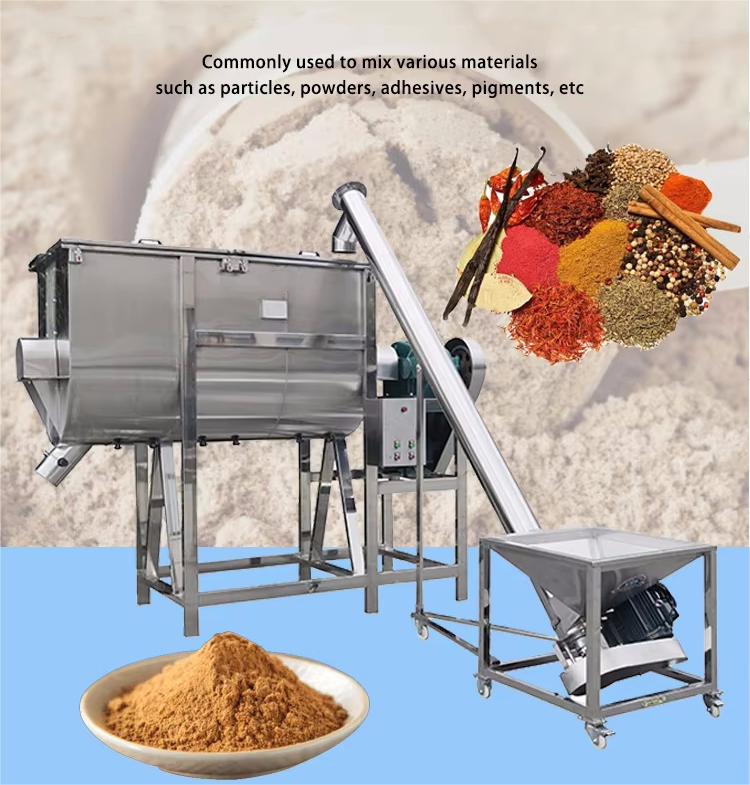

Vertical screw conveyor mixer is a high-efficiency mixing equipment widely used in feed, chemical, food and other industries. The equipment can achieve uniform mixing and conveying of materials through vertical structural design and screw conveying technology. This article will introduce the working principle, structural composition, application scenarios and advantages of vertical screw conveyor mixer in detail.

The working principle of vertical screw conveyor mixer mainly includes the following steps:

Feeding process:

Material feeding: The material to be mixed enters the mixer through the feeding port. The feeding port is usually designed at the top of the equipment for easy operation and feeding.

Mixing process:

Screw conveying: A vertical screw conveying device is provided inside the mixer. Driven by an electric motor, the spiral blade conveys the material from the bottom to the top during rotation.

Circular mixing: During the conveying process, the material is lifted from the bottom to the top due to the driving force of the screw, and then falls freely under the action of gravity, forming an up and down cyclic mixing process.

Uniform distribution: The continuity and cyclicity of the screw conveying make the material constantly flip and alternate in the mixing barrel, ensuring the uniform distribution and full mixing of the material.

Discharging process:

Mixing completed: When the material reaches the predetermined mixing time and uniformity, the uniformly mixed material is discharged through the discharging port and enters the subsequent processing or packaging link.

The vertical screw conveyor mixer is mainly composed of the following parts:

Frame: supports the entire equipment, usually made of steel or stainless steel.

Mixing barrel: the main component for storing and mixing materials, with a smooth interior and made of stainless steel or carbon steel.

Screw conveyor: a vertical spiral structure used to lift and mix materials, and the drive system consists of a motor and a reducer.

Feeding port and discharging port: used for material delivery and discharge, with reasonable design and easy operation.

Control system: controls the start, stop and mixing time of the equipment to ensure safe operation. 、

Vertical screw conveyor mixers are widely used in the following scenarios:

Feed processing: used to mix various feed ingredients, such as grain powder, soybean meal, fish meal, etc., to ensure the uniform distribution of feed ingredients and improve feed quality.

Chemical industry: used to mix various chemical raw materials, such as powder, granules, liquids, etc., to meet the production needs of different chemical products.

Food processing: used to mix various food raw materials, such as flour, sugar, spices, etc., to ensure the uniformity and stability of food formulas.

Building materials industry: used to mix building materials such as cement, sand, lime, etc. to ensure the uniformity and quality of building materials.

Compared with other mixing equipment, the vertical screw conveyor mixer has the following significant advantages:

Efficient mixing: Through the optimized screw conveying design, it can achieve uniform mixing of materials in a shorter time and improve production efficiency.

Compact structure: The vertical design occupies a small area and is suitable for production sites with limited space.

Easy to operate: The equipment has a simple structure and is easy to operate, suitable for operators of different technical levels.

Easy to clean: The mixing barrel and screw conveying device are reasonably designed, easy to disassemble and clean, and reduce the risk of cross contamination.

Wide range of applications: Suitable for mixing a variety of materials, not limited by the type of raw materials and formula, and has strong adaptability.

Strong durability: High-quality components and materials ensure the durability and stability of the equipment in long-term use.

As an efficient and compact mixing equipment, the vertical screw conveyor mixer is widely used in feed, chemical, food and other industries. It can not only improve the uniformity of materials and ensure product quality, but also has the advantages of simple operation, easy cleaning, and wide application range. With the increasing demand for mixing equipment in various industries, vertical screw conveyor mixers will play an important role in more fields and provide strong support for improving production efficiency and product quality.

Dahan Machinery is committed to providing high-quality equipment to meet the needs of customers. Our vertical screw conveyor mixers are manufactured using advanced production technology and high-quality materials. They have stable performance and reliable quality assurance and are suitable for a variety of industries, such as food processing, chemicals, building materials, etc. Our vertical screw conveyor mixers are reasonably priced and cost-effective. We focus on product quality and after-sales service to ensure that customers can get a satisfactory use experience after purchase. For more details or to obtain a quote, please feel free to contact us and we will serve you wholeheartedly.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.