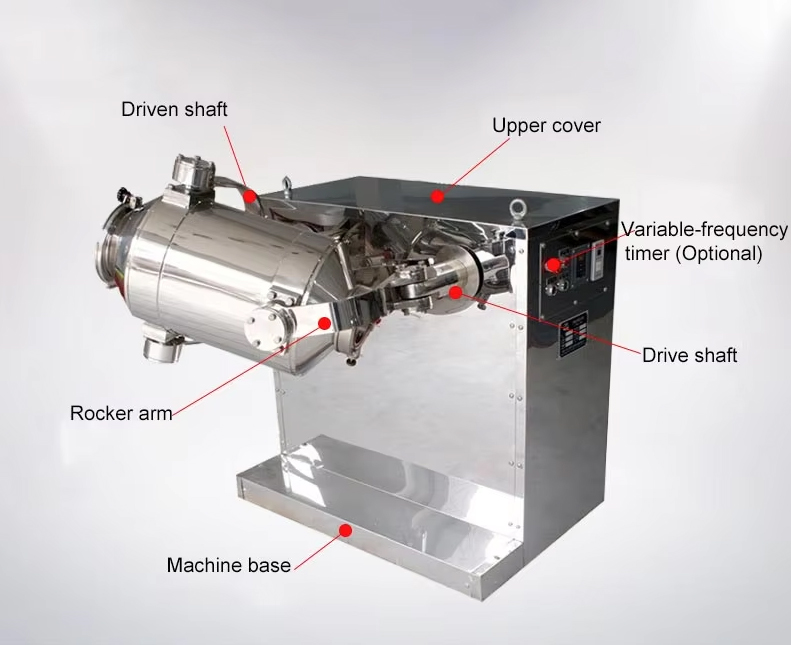

Since the mixing barrel of the three-dimensional motion mixer has the function of multi-directional operation, the flow and diffusion of various materials are accelerated during the mixing process. At the same time, it avoids the material gravity segregation and accumulation caused by the centrifugal force of general mixers. There is no dead angle in the mixing, which can effectively ensure the best quality of the mixed materials. The three-dimensional mixer is composed of the base, transmission system, electrical control system, multi-directional motion mechanism, mixing barrel and other components. The mixing barrel that is in direct contact with the material is made of stainless steel, and the inner and outer walls of the barrel are polished. The mixing barrel of the machine moves in multiple directions, the material has no centrifugal force, no gravity segregation, stratification, and accumulation, and the components can have a large weight ratio. The mixing rate is more than 99.9%, which is an ideal product among various mixing equipment. The barrel loading rate of this machine is large, up to 90% (only 40% for ordinary mixers), with high efficiency and short mixing time. The mixing barrel of the machine moves in multiple directions, the material has no centrifugal force, no gravity segregation, stratification, and accumulation, the components can have a large difference in weight ratio, and the mixing rate can reach more than 99.9%.

The barrel with materials is driven by the driving shaft to make repeated composite movements such as translation, rotation, and tumbling, which prompts the materials to make three-way composite movements along the fulcrum, thereby realizing the mutual flow, diffusion, accumulation, and doping of various materials to achieve a more uniform mixing purpose.

The mixing barrel moves in multiple directions, the material has no centrifugal force, no gravity segregation, stratification, and accumulation, the components can have a large difference in weight ratio, and the mixing rate is high. It is the most ideal product among various mixers at present.

There are many cross-mixing points of materials in the barrel, the mixing effect is high, and the uniformity can reach more than 99.9%

The barrel loading rate is large, up to 90% (ordinary mixers are only 50%), with high efficiency and short mixing time.

The cylinder has arc transitions at all places and has been precisely polished.

Used for high uniformity mixing of powdered and granular materials in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, defense industry and various scientific research units.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.