As an important sugar crop, sugarcane pulp processing involves multiple links, among which the mixing of sugarcane pulp is crucial. The quality of sugarcane pulp mixing directly affects the efficiency of subsequent sugar juice extraction and the quality of syrup, while the traditional mixing method is often inefficient and difficult to ensure the uniformity and stability of mixing. In recent years, Sugarcane pulp ribbon mixer, as an efficient and energy-saving mixing equipment, has gradually been favored by sugar mills. Sugarcane pulp for ribbon mixer is a special equipment used for mixing materials such as sugarcane pulp. It mixes sugarcane pulp and other materials evenly through the action of spiral belt.

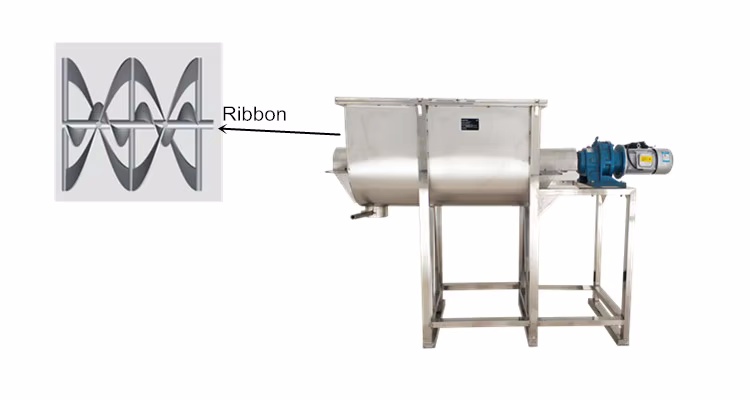

Sugarcane pulp for ribbon mixer is mainly composed of body, spiral belt, transmission device, feed port, discharge port and other parts. The body is usually made of stainless steel, which is corrosion-resistant and easy to clean. The spiral belt is generally made of wear-resistant materials, and different spiral shapes are designed according to the characteristics of different materials. The transmission device is responsible for driving the spiral belt to rotate, generally driven by a motor reducer, and can achieve multiple speed adjustments to meet different mixing requirements.

The working principle is to use the rotation of the spiral ribbon to drive the sugarcane pulp to mix. The spiral structure of the spiral ribbon can continuously roll and squeeze the material to make it fully mixed. At the same time, the rotation of the spiral ribbon can also promote the flow of materials, avoid sedimentation and dead corners, and ensure the uniformity and stability of the mixing.

The main components of the sugarcane pulp ribbon mixer, each part plays an important role, and its main components usually include the following parts:

Frame: The frame is the supporting structure of the entire equipment, usually made of steel or alloy, with sufficient strength and stability to support the installation and operation of other components.

Screw ribbon: Responsible for mixing and stirring the raw materials. The screw ribbon is usually made of stainless steel or other corrosion-resistant materials, with wear and corrosion resistance.

Motor: The motor provides power to drive the rotation of the screw ribbon, usually installed on one side or the top of the mixer, and transmits power to the screw ribbon through the transmission device.

Feed port: The feed port is usually located at one end of the mixer, used to put in raw materials such as sugarcane pulp.

Discharge port: The discharge port is usually located at the other end of the mixer, used to take out the mixed mixture such as sugarcane pulp from the equipment.

Control system: The control system usually includes electrical control cabinets, push button switches and other equipment to control the start, stop, speed regulation and other operations of the mixer.

Compared with the traditional mixing method, sugarcane pulp for ribbon mixer has the following advantages:

High efficiency and energy saving: The rotation of the spiral ribbon can quickly and effectively mix the sugarcane pulp evenly, which is more efficient than the traditional mixing method and saves costs.

Even mixing: The spiral structure of the spiral ribbon can fully roll and squeeze the material to avoid sedimentation and dead corners, ensuring the uniformity and stability of the mixing.

Easy operation: Sugarcane pulp for ribbon mixer is easy to operate. Just put the sugarcane pulp into the machine body and start the machine to mix.

Compact structure: It occupies a small area, is easy to install and maintain, and is suitable for the spatial layout of various sugar factories.

Corrosion-resistant material: The machine body and spiral ribbon are usually made of stainless steel, which is corrosion-resistant and can be used for a long time in a humid and high temperature environment.

High safety: The machine body is reasonably designed, the safety protection measures are perfect, and the safety of operators is guaranteed.

Sugarcane pulp for ribbon mixer is widely used in the sugarcane sugar industry, mainly used in the following links:

Pretreatment of sugarcane pulp: Mix sugarcane pulp with other additives (such as lime milk, clarifier, etc.) for pretreatment to prepare for subsequent sugar juice extraction.

Mixture of syrup: Mix syrups of different concentrations to meet the needs of different products.

Treatment of bagasse: Mix bagasse with water for hydrolysis to improve the utilization rate of bagasse.

To choose a suitable sugarcane pulp for ribbon mixer, the following factors need to be considered:

Mixing amount: Determine the required mixing amount and choose the appropriate model to avoid insufficient or excessive capacity.

Mixing requirements: Consider the requirements of mixing uniformity and stability, and choose the appropriate ribbon shape and speed.

Material properties: Consider the viscosity, density and other properties of sugarcane pulp, choose the appropriate material and structure to ensure the mixing effect and equipment life.

Budget: Choose equipment with high cost performance according to the budget.

In order to ensure the normal operation of sugarcane pulp for ribbon mixer and extend the life of the equipment, the following maintenance is required:

Regularly clean the body, screw belt and other parts to remove residues and avoid corrosion and blockage.

Regularly check the transmission device to ensure smooth operation and replace worn parts in time.

Avoid overloading the machine to prevent damage to the motor and screw belt.

Regularly check the equipment safety protection device to ensure the safety of the operator.

In short, as an efficient, energy-saving, safe and reliable mixing equipment, sugarcane pulp for ribbon mixer plays an increasingly important role in the sugarcane sugar industry, providing a strong guarantee for improving the efficiency of sugarcane sugar making, improving the quality of syrup and reducing production costs. With the continuous development of technology, sugarcane pulp for ribbon mixer will also be continuously updated and upgraded to contribute more to the development of the sugarcane sugar industry.

Dahan manufacturers usually provide comprehensive technical support and after-sales service, including equipment selection recommendations, installation and commissioning, operation training, and maintenance services. Various types of mixers are available for you to choose from, and users can obtain customized solutions through manufacturers to meet specific production needs. Dahan Sugarcane Pulp for Ribbon Mixer Manufacturer also provides design selection, trial machine with materials, 72-hour free door-to-door delivery, after-sales maintenance and other services, with 365-day quality assurance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.