Stainless steel dry-wet feed mixer is a kind of equipment specially designed for mixing dry and wet feed, which is widely used in animal husbandry, feed processing and agricultural production. This equipment is a kind of stainless steel feed mixer. It not only has the ability of efficient and uniform mixing, but also ensures the hygiene and safety of feed during processing. This article will introduce the working principle, structural composition, application scenarios and advantages of stainless steel dry-wet feed mixer in detail.

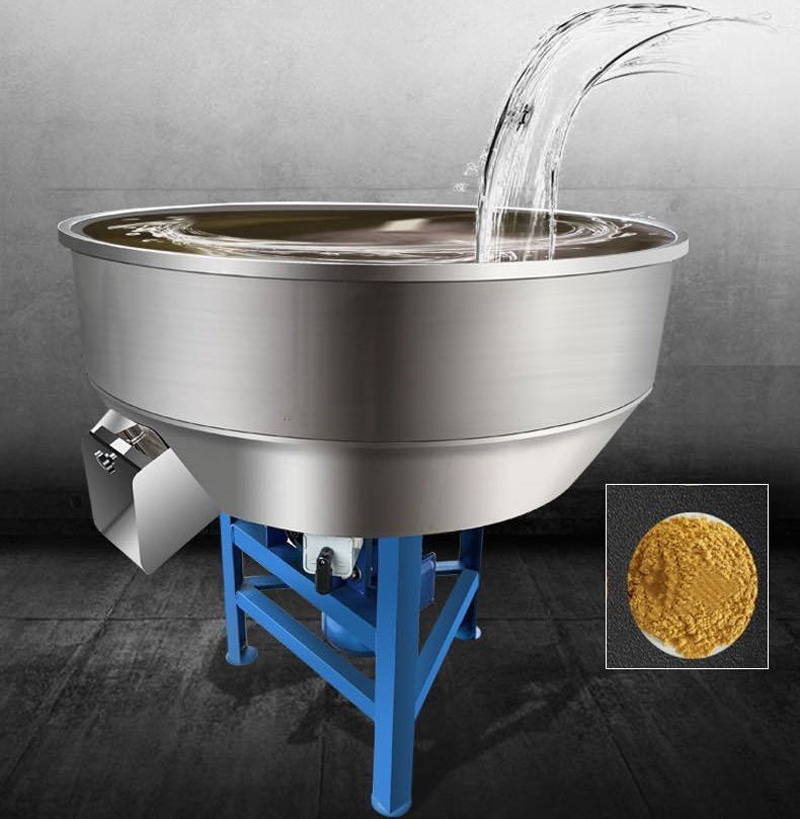

Feeding process:

Dry feed feeding: dry feed ingredients (such as grain powder, soybean meal, etc.) are fed into the mixer through the feeding port.

Wet feed feeding: liquid ingredients (such as water, grease, additive solution, etc.) are evenly added through a special liquid feeding port or spray device.

Mixing process:

Mechanical mixing: The mixer is equipped with a stirrer, which is driven by an electric motor to rotate or flip the stirrer. Common stirrer forms include spiral ribbon type, paddle type and double shaft type.

Uniform mixing: The rotation or flipping movement of the stirrer fully mixes the dry and wet materials to form a uniform mixture. During the mixing process, the interaction between dry and wet materials makes the feed ingredients evenly distributed.

Discharging process:

Mixing is completed: When the feed reaches the predetermined mixing time and uniformity, the mixed feed is discharged through the discharge port and enters the subsequent processing or packaging link.

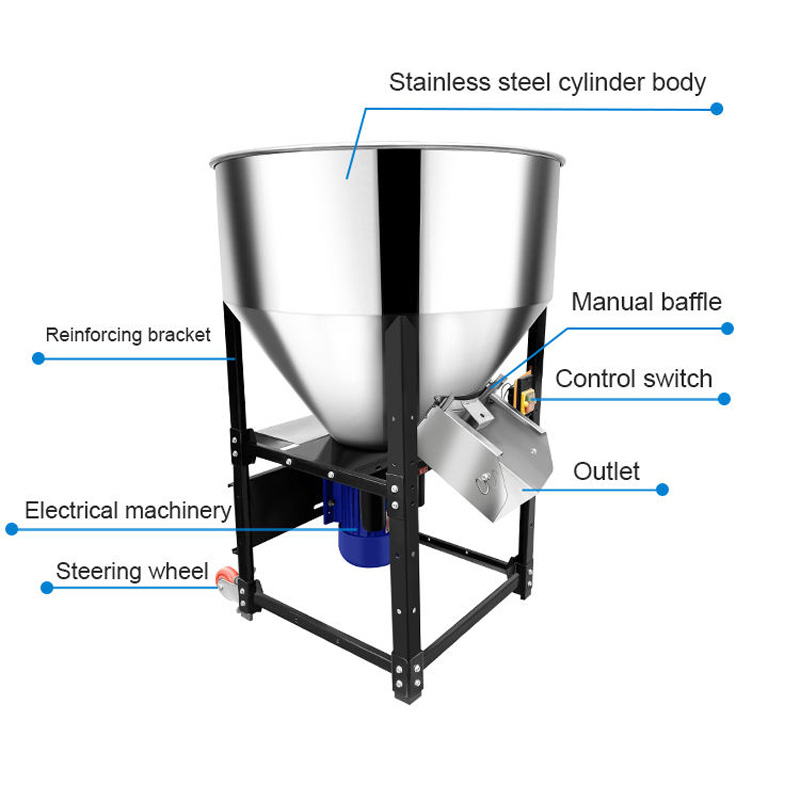

Frame: The structural frame that supports the entire mixer. Usually made of stainless steel or other corrosion-resistant materials.

Mixing drum: The main component for storing and mixing feed, with a smooth interior to reduce material residue.

Mixer: A key component for mixing dry and wet feed, designed in the form of spiral ribbon, paddle or double shaft.

Motor and reducer: The motor provides the power source for the mixer to rotate. The reducer is used to control the speed of the mixer.

Feeding port and discharge port: The feeding port is used for the delivery of dry and wet materials. The discharge port is usually equipped with a sealing device to prevent leakage.

Control system: The control panel is used to control the start, stop and mixing time of the mixer, usually including buttons, switches or touch screens.

Safety devices: including emergency stop button and safety lock, etc., to ensure the safety of equipment operation.

Livestock farms: Stainless steel dry-wet feed mixer is suitable for mixing feed for various livestock and poultry such as pigs, cattle, sheep, chickens, ducks, etc., to ensure the uniform distribution of feed ingredients and improve feeding effect.

Feed processing enterprises: used to produce various compound feeds and premixed feeds to meet the needs of different customers.

Agricultural production: helps farmers to prepare feed by themselves, reduce feed costs, and improve the quality and yield of agricultural products.

Laboratories and research institutions: used for feed formula research and testing, providing small batch and high-precision feed mixing.

Efficient mixing: Through the optimized mixing design, it can achieve uniform mixing of dry and wet feed ingredients in a shorter time and improve production efficiency.

Hygiene and safety: Stainless steel material prevents material contamination and corrosion, ensuring the hygiene and safety of feed during processing.

Easy operation: The equipment has a simple structure and is easy to operate, suitable for operators of different technical levels.

Easy to clean: The mixing drum and agitator are reasonably designed, easy to disassemble and clean, reducing the risk of cross contamination.

Wide range of applications: Suitable for mixing a variety of dry and wet feed ingredients, not limited by the type of raw materials and formula.

Strong durability: Stainless steel material and high-quality components ensure the durability and stability of the equipment in long-term use.

As an efficient, hygienic and safe mixing equipment, stainless steel dry-wet feed mixer is widely used in animal husbandry, feed processing and agricultural production. It not only improves the uniformity of feed and ensures balanced intake of animal nutrition, but also has the advantages of simple operation, easy cleaning and wide application. With the continuous development of animal husbandry and agriculture, stainless steel dry-wet feed mixer will play an important role in more fields and provide strong support for improving production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.