The single cone double screw mixer is a commonly used mixing equipment and is widely used in industrial production. Choosing a suitable single cone double screw mixer model requires comprehensive consideration of factors such as mixing requirements, capacity, mixing effect, equipment quality, maintenance and after-sales service. Make sure to choose the right model based on your actual needs and pay attention to the quality and durability of the device. Consulting other user reviews and consulting professionals can provide more comprehensive information and advice. By comprehensively considering these factors, you will be able to choose the most suitable single cone double screw mixer model to improve production efficiency and product quality.

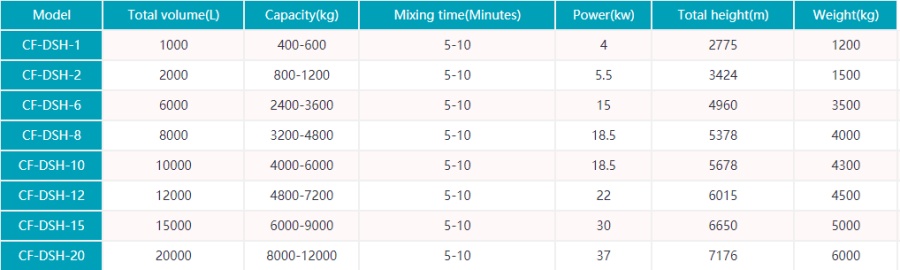

Single cone double screw mixer models may vary according to different manufacturers and specific requirements. Usually the model will include parameters such as capacity, power, height, mixing speed, etc. For example, a common model might be the CF-DSH-8, where it represents a mixer with a capacity between 3200-4800kg. This type of mixer usually has moderate power, mixing speed and is suitable for certain scale production.

First, you need to clarify your mixing needs, including the ingredients of the mixture, the mixing amount and the mixing effect requirements. Different models of single cone double screw mixers are suitable for different mixtures, such as powdery, granular or slurry materials. Choose the right model based on your specific needs to ensure it can effectively mix the materials you need.

The capacity of a single cone twin screw mixer is one of the important factors to consider when selecting a model. Capacity selection should be based on your production needs and expected mix volumes. If you need to mix large batches, choosing a model with a larger capacity can increase productivity. However, be careful not to select a capacity that is too large to avoid wasting resources.

Different models of single cone double screw mixers have different mixing effects and process characteristics. Some models may have higher mixing uniformity and shorter mixing times, while others may be suitable for special mixing processes. Before choosing a model, understand the mixing effect and process characteristics of the mixer to ensure that it can meet your mixing requirements.

The quality and durability of equipment are very important for long-term stable operation. Choosing a well-known brand or a supplier with a good reputation can provide a more reliable and durable single cone double screw mixer. In addition, understanding the manufacturing process, material selection and quality control system of the equipment are also important indicators for evaluating the quality of the equipment.

When selecting a single cone double screw mixer model, consider the maintenance and after-sales services provided by the supplier. Ensure that suppliers can provide timely maintenance and technical support to reduce the impact of equipment failure on production. In addition, understanding the supplier's spare parts availability and after-sales service terms are also important considerations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.