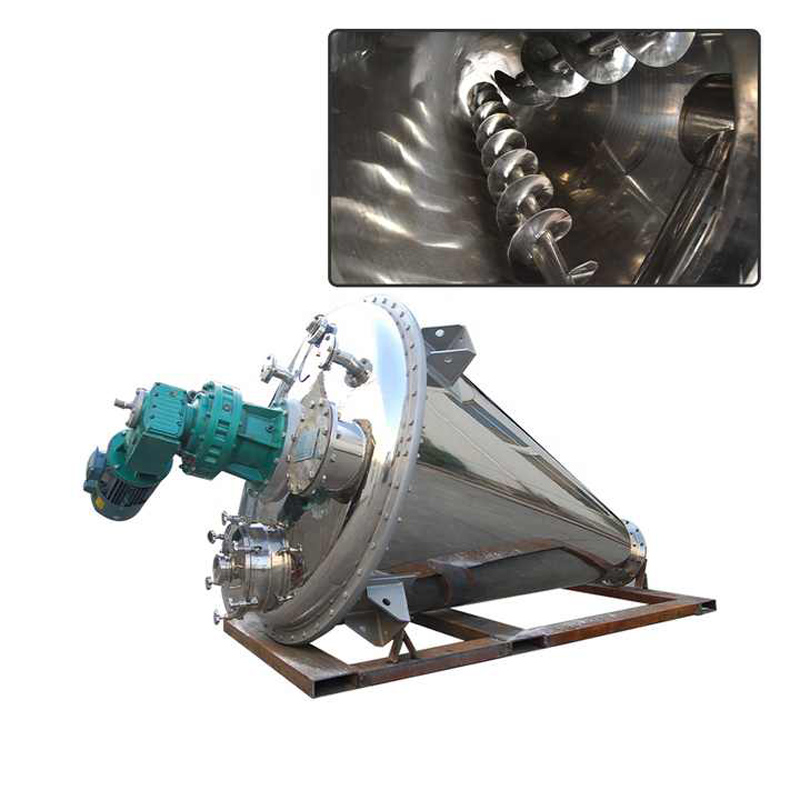

Single cone double screw mixer is a commonly used mixing equipment with the following characteristics:

Single cone design: The mixing barrel of the single cone double screw mixer is cone-shaped and has a large volume and mixing space. This design is beneficial to improving the mixing effect and material fluidity, making the mixing more uniform.

Double spiral arrangement: There are two mutually spiral stirring spirals inside the mixing barrel, which are spirally arranged along the barrel wall. This double screw design can push materials up and down to achieve better mixing effects.

Uniform mixing: The design of the double screw and the structure of the conical barrel allow the materials to be fully sheared, folded and exchanged during the mixing process. This allows the materials of various ingredients to be fully mixed and achieve a uniform mixing effect.

Efficient mixing: The rotation and pushing action of the double helix makes the material flow rapidly in the mixing barrel, with short mixing time and high mixing efficiency. This helps increase productivity and reduce energy consumption.

Wide range of applicable materials: Single cone double screw mixer is suitable for mixing a variety of powdery, granular and viscous materials, including materials in chemical, pharmaceutical, food, metallurgy and other industries.

Adaptable to a wide range of capacity: According to different production needs, the volume of the single cone double screw mixer can range from tens of liters to thousands of liters, which can meet the production requirements of different scales and outputs.

Easy operation: Single cone double screw mixers are usually equipped with user-friendly control panels and operating interfaces, so operators can easily master the operation of the equipment and adjust mixing parameters.

Easy maintenance: There are no complex transmission devices and wearing parts inside the mixing barrel, so cleaning and maintenance are relatively simple. At the same time, the equipment adopts a dust-proof sealing design to reduce dust leakage and improve the cleanliness of the working environment.

High equipment stability: The single cone double screw mixer adopts high-quality materials and precise manufacturing processes, and has good mechanical strength and stability, ensuring long-term stable operation of the equipment.

Safety protection measures: Equipment is usually equipped with a variety of safety protection devices, such as overload protection, motor overheating protection, leakage protection, etc., to ensure the safety of operators and equipment.

Customized according to needs: The single cone double screw mixer can be customized according to the specific needs of users, including customization of volume, materials, motor power, control systems, etc., to meet the requirements of different industries and processes.

Integration of supporting equipment: The single cone double screw mixer can be integrated with other equipment, such as feeding system, unloading system, dust removal system, etc., to form a complete production line to improve production efficiency and automation. To sum up, the single cone double screw mixer has the characteristics of obvious structural features, good mixing effect, strong adaptability, convenient operation and maintenance, safety, reliability and customization. This makes it a commonly used mixing equipment in multiple industries and is widely used in material mixing and processing processes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.