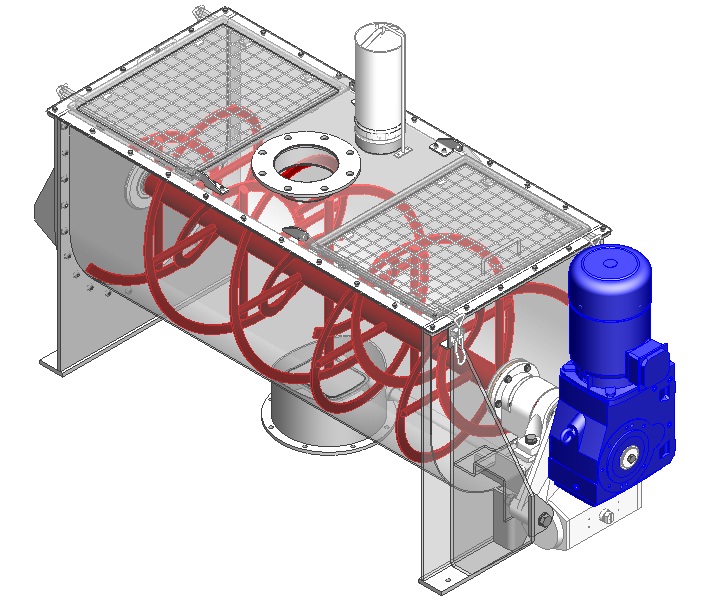

Large-scale feed production ribbon mixer is a mixing equipment specially designed for large-scale feed production,and it is a type of feed ribbon mixer. It adopts the structure of spiral blades and spiral belts to evenly mix different types of feed ingredients through pushing, turning and stirring. This equipment has the characteristics of stable structure, convenient operation and good mixing effect. It can meet the mixing needs of large quantities of feed raw materials and improve the quality and nutritional balance of feed. Through the pushing, turning and stirring of the spiral blades and spiral belts, the feed ingredients are fully mixed. This equipment has been successfully used by customers such as large feed processing plants.

Large feed production ribbon mixers are widely used in feed production fields such as large feed processing plants and farms. It is suitable for mixing large quantities of feed raw materials, including grains, feed powder, additives, etc. This equipment can meet the requirements for mixing uniformity and production efficiency in the feed production process.

1. Uniform mixing: Large-scale feed production ribbon mixers achieve uniform mixing of feed raw materials through the pushing, turning and stirring functions of the spiral blades and ribbons. The mixed feed has a uniform distribution of ingredients, avoiding stratification between particles and improving the quality and nutritional balance of the feed.

2. Stable structure: The device adopts a solid structural design and has good stability and durability. It can withstand the mixing work of large quantities of feed ingredients, ensuring the stability and reliability of the equipment in long-term operation.

3. Easy to operate: The large-scale feed production ribbon mixer adopts an automatic control system and is simple and convenient to operate. Users only need to set parameters such as mixing time and speed, and the equipment can automatically complete the mixing process, reducing the workload of the operator.

4. Good mixing effect: This equipment achieves full mixing of feed raw materials through the continuous pushing, turning and stirring of the spiral blades and spiral belts. The mixed feed particles not only have uniform ingredients, but also have improved physical properties between particles, improving the solubility and digestibility of the feed.

1. Feeding: Feed raw materials enter the feeding port of the large-scale feed production ribbon mixer through a feeder or other conveying equipment.

2. Spiral blade pushing: The spiral blade is located inside the mixer and fixed on the spiral shaft. When the screw shaft rotates, the screw blades push the feed materials forward. The pushing effect causes particles to collide and flip over each other, promoting the mixing effect.

3. Ribbon movement: The ribbon is located outside the spiral blades and moves in cooperation with the spiral blades. The movement of the ribbon increases the mixing degree of the particles, making the particles more evenly distributed inside the mixer.

4. Discharge: The mixed feed is discharged from the discharge port of the mixer. The discharge speed can be controlled by adjusting the opening and closing of the discharge port.

A large feed processing plant introduced a large-scale feed production ribbon mixer to mix feed raw materials. After using the equipment, they found that the mixing effect was significantly improved and the uniformity of feed ingredients was greatly improved. This allows them to produce feed products of better quality and more uniform composition, increasing their product competitiveness and market share.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.