Paddle mixers are versatile industrial mixing machines used in a wide range of applications across various industries such as food processing, pharmaceuticals, chemicals, and construction. These mixers are designed to blend dry powders, granules, and other solid materials efficiently and uniformly. Below is an overview of the features, working principles, applications, and benefits of paddle mixers in industrial mixing applications.

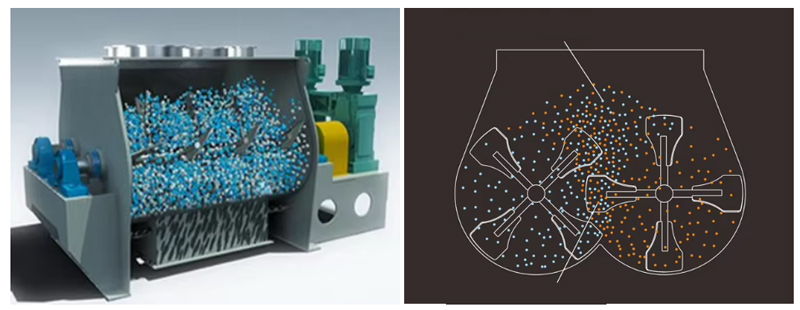

Paddle Design: Paddle mixers are equipped with paddles or agitators that rotate within a mixing chamber to blend materials effectively.

Variable Speed: Many paddle mixers offer variable speed control to adjust the mixing intensity based on the specific requirements of the materials being processed.

Multiple Sizes: Paddle mixers come in various sizes, from small laboratory-scale models to large industrial units, to accommodate different production capacities.

Durable Construction: These mixers are typically constructed from robust materials such as stainless steel to withstand the rigors of industrial mixing operations.

Customizable Configurations: Paddle mixers can be customized with additional features such as heating/cooling jackets, vacuum capabilities, and specialized paddle designs for specific applications.

Easy Maintenance: Many paddle mixers are designed for easy cleaning and maintenance, with quick access to internal components for inspection and servicing.

Material Loading: The materials to be mixed are loaded into the mixing chamber of the paddle mixer.

Agitation: The paddles or agitators rotate within the mixing chamber, creating a tumbling or cascading motion that effectively blends the materials.

Uniform Mixing: The design of the paddles ensures that the materials are mixed uniformly, resulting in a homogenous mixture.

Discharge: Once the mixing process is complete, the blended material is discharged from the mixer for further processing or packaging.

Food Processing: Paddle mixers are used in the food industry for mixing ingredients in the production of baked goods, snacks, confectionery, and other food products.

Pharmaceuticals: These mixers are employed in pharmaceutical manufacturing for blending powders, granules, and other pharmaceutical ingredients.

Chemicals: Paddle mixers play a vital role in the chemical industry for mixing and blending various chemicals, pigments, and additives.

Construction Materials: Paddle mixers are utilized in the construction industry for mixing dry mortar, cement, plaster, and other building materials.

Plastics and Polymers: Paddle mixers are used in the plastics industry for blending polymer resins, additives, and colorants.

Cosmetics and Personal Care: Paddle mixers are employed in the production of cosmetics, lotions, creams, and other personal care products.

paddle mixers are essential equipment in industrial mixing applications, offering efficient and uniform blending of materials across a wide range of industries. By utilizing paddle mixers, businesses can enhance their production processes, improve product quality, and achieve greater efficiency in their mixing operations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.