Inclined intensive mixer is a commonly used industrial mixing equipment, widely used in food, chemical, pharmaceutical, building materials and other industries. Its mixing direction is divided into forward and reverse directions. It adopts an inclined container and an internal agitator, which can efficiently mix powdery, granular or viscous materials evenly to ensure product quality and production efficiency.

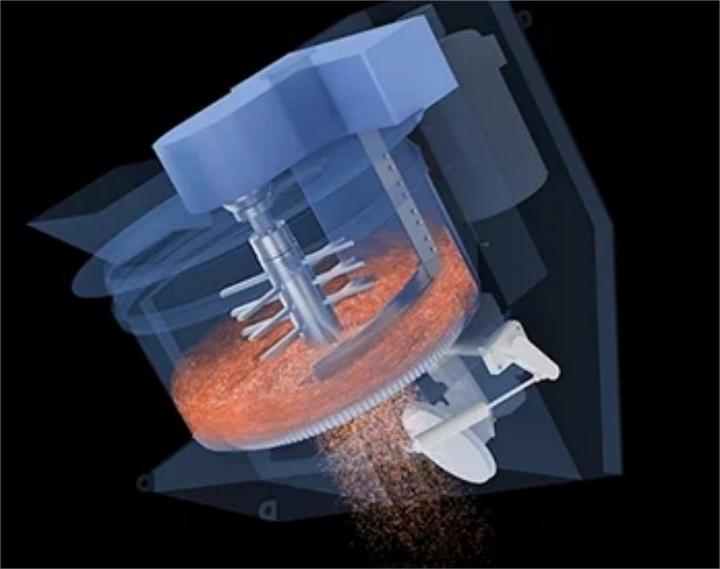

Inclined intensive mixer has a unique mixing principle that ensures 100% of the materials are mixed, obtaining the best product quality in the shortest mixing time, and is used for batch operations. While the mixing device rotates at high speed, the cylinder is driven by the reducer to rotate, and the mixing cylinder is tilted at a certain angle to achieve a three-dimensional mixing mode, making the materials turn more violently and mix more evenly.

The working principle of the inclined intensive mixer is based on the tilting of the container and the movement of the internal stirrer. When the equipment is started, the container tilts to move the material to one side, and at the same time the internal agitator begins to rotate or flip, stirring the material from one side to the other, achieving all-round mixing. The inclined design can effectively improve the mixing efficiency and ensure that each particle is fully mixed.

The process processing method of the powerful mixer meets the special needs of production. The mature mixing technology can improve the quality of the mixture and meet the homogeneous mixing of different raw materials.

Excellent preparation of powdered or other mixtures in one machine.

Its structural design ensures no lumps on the mixing tool.

The uniformity of materials is easy to achieve, and the unique mixing quality prevents segregation of the mixture.

Both dry and wet materials can be mixed in batches or continuously.

Inclined intensive mixers are used in the food industry to mix flour, seasonings, granular foods, etc.

Used in the chemical industry to mix powder and granular materials.

Used in the pharmaceutical industry to mix pharmaceutical raw materials, etc.

Its flexibility and efficiency make it an indispensable and important equipment in the production process of various industries.

The inclined mixer rotates the material trough together, and at the same time, the agitator rotating in the same direction in the centrifugal position generates a force that can shear the material. The speed difference formed in the complex flow achieves a fine and fine mixing effect of the material.

In the rotating material trough, the material is sent to the scraper arm and turned over under the action of the scraper blade, which promotes macroscopic mixing in the up and down directions.

The scraper blades continuously peel off the materials still remaining at the bottom and edge of the tank and send them to the mixer, promoting the material to be discharged in a short time at the end of the mixing cycle.

In general, the inclined intensive mixer, as an efficient and reliable industrial mixing equipment, provides important support for the production of various industries. It has advanced mixing principles and can meet the special production needs of various industries. A variety of raw materials are fully mixed under the action of the tilt mixer, which increases the material contact area, promotes chemical reactions, improves physical changes, and improves the texture of the products produced. Uniform, no difference, stable performance, avoiding problems of unstable product performance and color difference caused by uneven mixing.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.