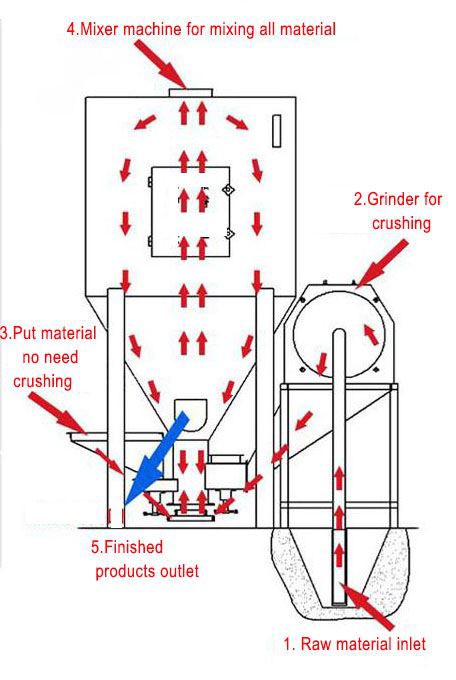

Vertical crushing and mixed machine is a commonly used crushing and mixing equipment, mainly used for the crushing and mixing process of granular materials. The working principle of the Vertical crushing and mixed machine is simple and clear, and it is easy to operate. The material is broken into smaller particles through the crusher, and then the broken materials are mixed through the mixer. Vertical crushing and mixed machine is widely used in chemical, pharmaceutical, food, feed and other industries for crushing and mixing granular materials to improve product uniformity and quality.

Vertical crushing and mixed machine usually consist of a crusher, agitator, feed port, discharge port, motor and transmission device. The crusher is located on the upper part of the machine and is used to crush materials. The agitator is located at the bottom of the crusher and is used to mix the crushed materials.

Materials enter the vertical crushing mixer through the feed port. Under the action of the crusher, the materials are broken into smaller particles. The crusher usually consists of a rotating blade and a fixed blade. The relative movement of the blades cuts, impacts and crushes the materials.

The crushed materials fall from the crusher into the mixer. Agitators usually consist of rotating mixing blades and a fixed cylinder. The mixing blade stirs and turns the materials so that the materials can be fully mixed. The design and layout of the mixing blades can be adjusted as needed to achieve the mixing requirements of different materials.

Vertical crushing mixers are usually driven by a motor, which transmits power to the crusher and agitator through a transmission device. The motor drives the crusher and agitator to rotate to realize the crushing and mixing process of materials.

After mixing is completed, the material is discharged from the vertical crushing mixer through the discharge port. The discharge port is usually located at the bottom of the machine and can be adjusted as needed to control the discharge speed and amount of materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.