The twin shaft paddle mixer is a commonly used mixing equipment and is widely used in chemical, food, pharmaceutical and other industries. Through the high-speed rotation and interaction of the paddles, the materials are sheared, folded, diffused and convection to achieve uniform mixing of the materials. Its working principle is simple and effective, able to meet the mixing needs of different industries and provide efficient and reliable mixing solutions.

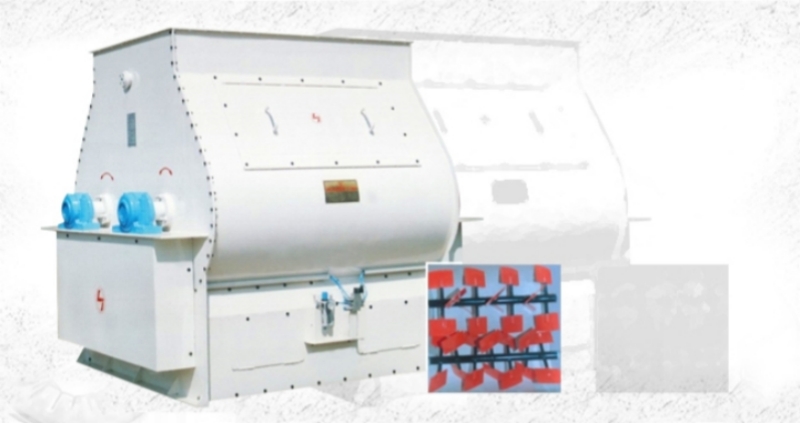

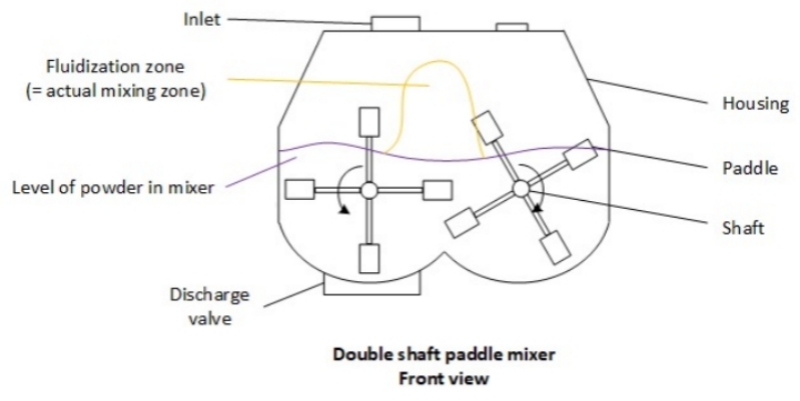

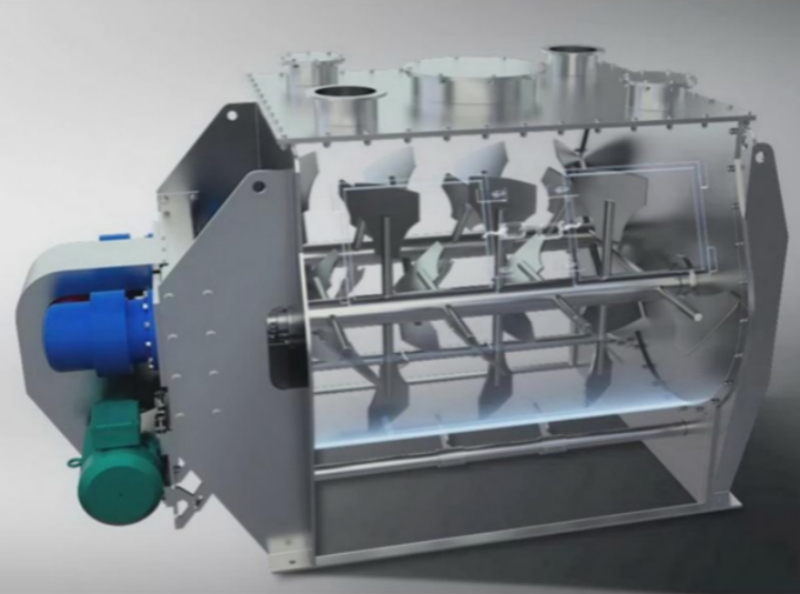

A twin shaft paddle mixer consists of a container and two horizontal shafts, with paddles mounted on each shaft. The arrangement of the shaft and blades can be designed according to the characteristics of the mixed materials and process requirements. The container is usually a closed cylindrical structure with a smooth interior and no dead ends to ensure the uniformity of the mixed materials.

First, put the materials to be mixed into the container of the mixer. Then, start the mixer's motor and the paddles on the two shafts begin to rotate at high speed. The rotation speed of the blade is usually high to generate sufficient centrifugal force and cutting force. When the paddle rotates, the material is pushed to both sides of the container by centrifugal force. At the same time, the shape and arrangement of the paddles cause the material to shear and fold between the two axes. This shearing and folding effect causes the material particles to intersect and collide with each other, promoting the mixing process.

As the paddle rotates, the material is pulled back to the central area of the container. This cyclic movement causes materials to continuously exchange positions, making the mixing between different particles and different components more uniform. At the same time, the rotation of the blades will also produce a convection effect, further promoting the mixing of materials.

The mixing effect of a twin shaft paddle mixer is affected by many factors, including the shape of the paddle, rotation speed, mixing time, and material properties. The shape of the blade can be selected according to the characteristics of the material and the mixing requirements. For example, the shape of the blade can be straight, beveled, curved, etc.

The choice of rotation speed should consider factors such as the viscosity, density and particle size of the material. Higher rotational speeds can increase shearing and folding effects, but may also increase energy consumption and mechanical wear. The mixing time needs to be determined according to the characteristics of the material and the mixing requirements to ensure that the required degree of mixing is achieved. In addition, the twin shaft paddle mixer can be equipped with other additional equipment, such as heating/cooling systems, spray devices, etc., to meet specific process needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.