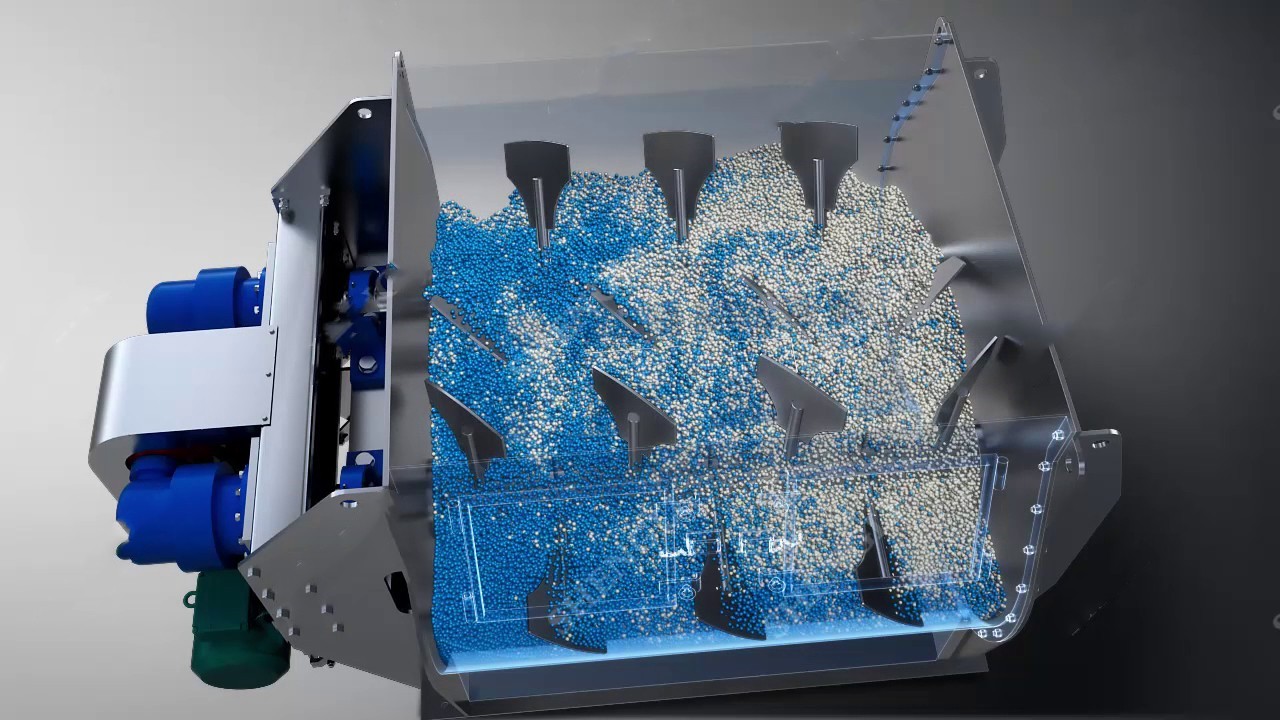

Gravityless Twin Shaft Paddle Mixer adopts a double-shaft paddle structure, which can evenly mix dry protein raw materials to ensure the quality and consistency of the mixed product.The Gravityless Twin Shaft Paddle Mixer for Dry Proteins is a piece of equipment specially designed for mixing dry protein raw materials. This mixer has efficient and reliable performance and is widely used in food processing, pharmaceutical, chemical and other industries

Food processing: used to mix dry protein powder, casein and other food raw materials to prepare various food products, such as protein drinks, protein nutrition bars, etc.

Pharmaceutical industry: used for mixing dry protein pharmaceutical raw materials to prepare tablets, capsules and other preparations.

Chemical industry: used to mix dry protein chemical raw materials and prepare various chemical products.

Efficient mixing: The twin-shaft paddle structure and zero-gravity design make the mixing effect more uniform, ensuring that dry protein raw materials are fully mixed and improving product quality.

Reliability: Using high-quality materials and advanced manufacturing processes to ensure the reliability and long life of the equipment.

Easy operation: The equipment is simple to operate and easy to control and adjust the mixing process to meet the requirements of different products.

Easy to clean: The equipment is easy to clean and maintain, reducing the risk of cross-contamination and meeting hygiene standards.

Safety: The equipment adopts safety protection measures to ensure the safety of operators.

The gravityless twin shaft paddle mixer for dry proteins uses the rotation and convection of the twin-shaft paddles to evenly mix the dry protein raw materials. The dry protein raw materials are put into the container of the mixer, and the double-shaft blades begin to rotate, generating strong convection and shear forces. Under the action of the twin-shaft paddles, the dry protein raw materials are continuously turned, pushed and mixed to achieve a uniform mixing effect.

A food processing company uses a gravityless Twin Shaft Paddle Mixer for Dry Proteins to prepare protein drinks. They put dry protein powder and other food ingredients into the mixer, and use the mixing action of the twin-shaft paddles to fully mix the various ingredients to ensure consistent product quality and taste. After using this mixer, their production efficiency has increased, product quality has been significantly improved, and it has been well received by customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.