Food additives are an indispensable part of the modern food industry. They can improve the color, flavor, taste, shelf life, etc. of food and meet people's diverse needs for food. Food additive powder ribbon mixer is the key equipment for evenly mixing various powdered additives. Through the rotating motion of the agitator, different types of food additive powders can be effectively mixed. This mixer is easy to operate and has a good mixing effect. It is suitable for mixing additives in the food production process, such as seasonings, pigments, preservatives, etc.

Horizontal single-axis ribbon mixer: Suitable for uniform mixing of powder preservatives such as potassium sorbate and sodium benzoate. It can be equipped with a temperature control jacket (±2℃ accuracy) to handle heat-sensitive additives such as nisin.

Horizontal double-axis ribbon mixer: The double-axis reverse ribbon design can handle the density difference (±0.3g/cm³) between vitamin premixes (VC, VD) and lactose carriers, and the mixing uniformity CV value is ≤5%23.

Vertical ribbon mixer: The vertical structure achieves gentle mixing of probiotic powder and microcapsule carriers through gravity circulation, and the survival rate of live bacteria is ≥95%37. Suitable for large-scale mixing of dietary fibers such as resistant dextrin and inulin.

The working principle of food additive for powder ribbon mixer is similar to that of pharmaceutical raw material powder ribbon mixer. Both are based on the rotating motion of the spiral ribbon to tumble and stir the powder material to achieve uniform mixing.

Movement of the spiral ribbon: When the spiral ribbon rotates, the outer spiral ribbon pushes the material upward, and the inner spiral ribbon brings the material downward to form a circular flow.

Tumbling of materials: During the circular flow, the material tumbles continuously, and different components contact each other to promote mixing.

Mixing uniformity: The design and rotation direction of the spiral ribbon can effectively overcome the static electricity and adhesion of the powder and ensure the uniformity of mixing.

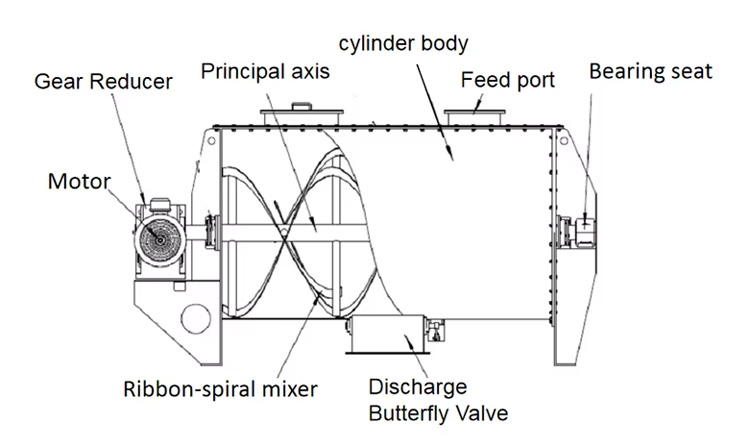

Mixing chamber: a mixing chamber used to hold food additive powder, usually with suitable capacity and structure to ensure effective mixing operation.

Spiral agitator: a core component of the mixer, which effectively mixes food additive powder through rotational motion to ensure uniform mixing effect.

Motor and transmission device: a motor and transmission device driving the spiral agitator, providing power support so that the spiral agitator can rotate and perform mixing operations.

Control system: a control system used to set mixing time, speed and other related parameters to ensure precise control of the mixing process.

Discharge port: used to take out the mixed food additive powder to facilitate subsequent production processes or packaging operations.

Frame: a structural frame that supports the entire mixer to ensure the stability and safety of the equipment.

High mixing efficiency: the spiral ribbon is reasonably designed, which can quickly and efficiently mix the additive powder evenly, shorten the production cycle and improve production efficiency.

High mixing uniformity: mixing uniformity is an important guarantee for food safety and quality. The spiral ribbon mixer can effectively eliminate the dead corners generated during the mixing process and ensure the uniformity and consistency of the additive powder mixing.

Simple and convenient operation: The equipment has a simple structure, is easy to operate and maintain, and can reduce the workload of operators.

Meet food safety standards: The material, process, and design all meet food safety standards to ensure the cleanliness and hygiene of the production process and guarantee food quality.

Strong scalability: Mixers of different sizes and configurations can be customized according to actual production needs to meet the production needs of different specifications.

Food additive for powder ribbon mixer is widely used in various food processing links, such as:

Seasoning production: Mix various spices, spices, seasoning powders, etc. to prepare various seasonings.

Baked food production: Mix flour, sugar, yeast, additives, etc. to prepare baked foods such as cakes and bread.

Beverage production: Mix various powdered additives, such as milk powder, powdered sugar, essence, etc. to prepare various beverages.

Meat product processing: Mix various additives, such as marinade, pigments, preservatives, etc. to process meat products.

Other food production: Mix various additives, such as thickeners, emulsifiers, stabilizers, etc., for the production of various foods.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

As an important part of food production, food additive for powder ribbon mixer plays a key role in ensuring food safety and improving food quality. I believe that with the continuous advancement of technology, food additive for powder ribbon mixer will continue to develop in the direction of intelligence, automation and multi-function, providing people with safer and more delicious food.

It can mix various types of additive powders by taking advantage of its own advantages.

Potassium sorbate, sodium benzoate: Rapid dispersion is achieved through double spiral ribbon reverse shearing, and the residual amount can be controlled at ≤0.02%, meeting the requirements of GB 2760 standard 25.

Nisin: When mixed with carrier powder, an inert gas protection system is required to avoid oxidative inactivation 27.

Vitamin premixes (VC, VD, etc.): Low shear force reverse spiral ribbon design is adopted, and the mixing uniformity CV value is ≤5%, reducing the loss of heat-sensitive components 57.

Mineral powder (calcium carbonate, ferrous sulfate): Silicon nitride ceramic coating spiral ribbon wear-resistant treatment is used to avoid metal contamination, and the mixing accuracy error is ≤0.3% 26.

Flavor and flavor (ethyl maltol, vanillin): The atomization spray system realizes uniform embedding of liquid flavor and carrier, and the aroma retention rate is ≥95% 57. Compound seasoning (chicken essence, spicy and fresh): supports the precise ratio of bulk raw materials (salt, sugar) and trace components (disodium nucleotides), with an error of ≤0.5%25.

Thickener (xanthan gum, carrageenan): The shear force of the double-screw ribbon can destroy the colloid agglomeration, and the viscosity consistency after mixing is improved by 50%56.

Leaving agent (sodium bicarbonate, potassium hydrogen tartrate): The temperature-controlled jacket is used to keep the mixing temperature ≤40°C to avoid premature reaction affecting the swelling effect67.

Probiotic powder: The inert gas protection mixing process makes the survival rate of live bacteria ≥97%, breaking through the 10% loss rate of the traditional process27.

Dietary fiber (resistant dextrin, inulin): The modular design supports simultaneous addition with liquid (oligosaccharide syrup), and the solubility is increased by 30% after mixing57.

Due to the particularity of food additives, we must ensure that the mixer meets the following points when selecting a mixer.

Material: The part in contact with the material must be made of food-grade stainless steel, commonly SUS304 or SUS316L, to meet food hygiene requirements and prevent material contamination.

Sealing: The shaft end seal and the discharge port seal must be good to prevent dust leakage from causing environmental pollution and material loss.

Cleanliness: The design should be easy to clean, minimize dead corners, facilitate thorough cleaning and production change, and prevent cross contamination.

Surface treatment: The surface in contact with the material usually needs to be polished (such as mirror polishing) to reduce material adhesion and facilitate cleaning.

No residual discharge: The design of the discharge valve should ensure that the material is emptied as much as possible and reduce residue.

Laboratory Type (5-50L): Suitable for new product development, formula experiments, small batch trial production, 304 stainless steel material, manual quick-opening material door

20-50L pilot series: Suitable for process verification and pilot production, mixing cycle 8-15 minutes, residual amount <0.1%.

100-1000L standard production line type: processing capacity 50-800kg per hour, motor power 3-15kW, reducer torque 200-1000N•m.

Dahan Machinery Manufacturing Co., Ltd. is deeply involved in the field of food additive mixing. Aiming at the characteristics of preservatives, nutritional enhancers, probiotic powder and other materials, the core products are made of 316L stainless steel, equipped with temperature control jacket (±1℃), silicon nitride ceramic wear-resistant spiral belt and inert gas protection system to meet the mixing needs of heat-sensitive and highly corrosive additives. We have provided customized solutions and 24-hour response services to more than 300 food companies around the world, enabling the safe production of food additives with the dual drive of technology and service.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.