Feed additive for small mixer machine is designed for small-volume feed additive mixing. It's primarily used to evenly blend trace additives such as vitamins, minerals, and enzymes with base powders. This addresses the mixing needs of small-batch premixes, experimental formulas, or small-scale farming operations. It offers a variety of types to meet the mixing requirements of diverse scenarios. It also supports full customization, including the choice of 304/316 stainless steel material, adjustable capacity from 5L to 100L, and the ability to add dust covers and micro-feed ports based on material characteristics, precisely matching the individual needs of different usage scenarios.

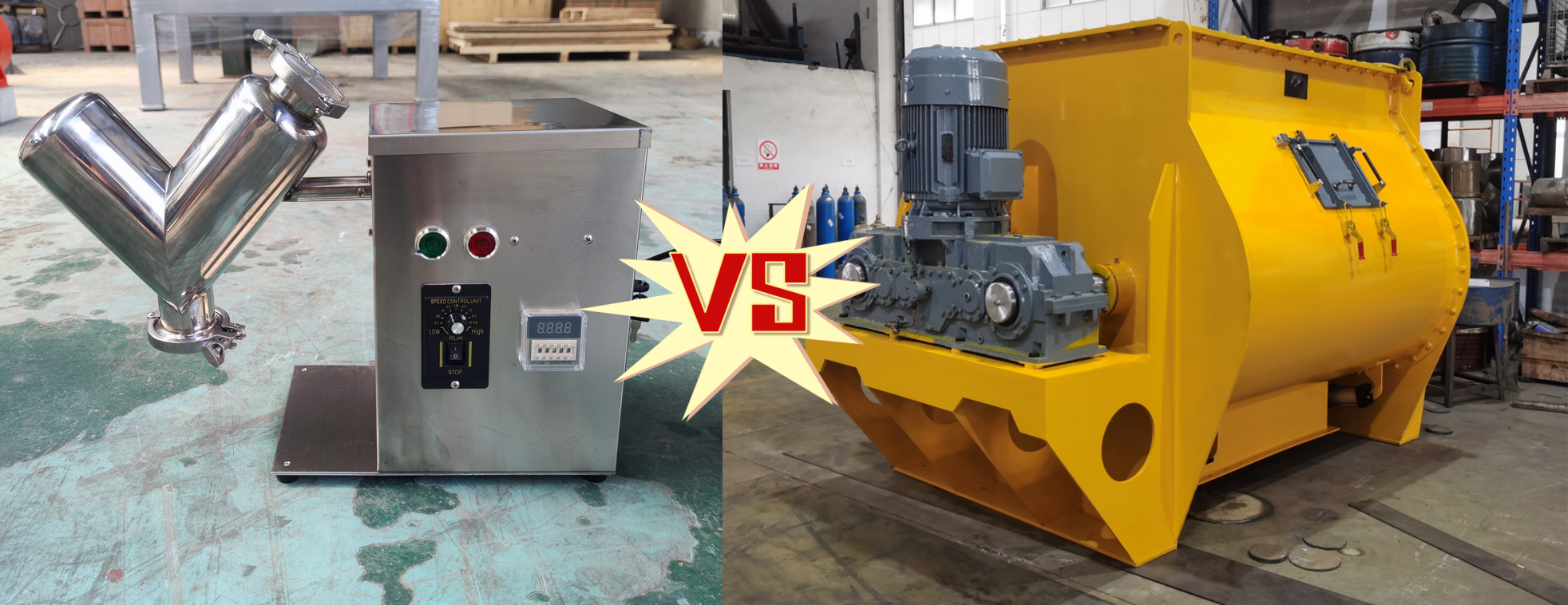

Small feed additive mixers are categorized into three types based on their structural differences: small horizontal, vertical, and V-type. Each type's unique design adapts to different small-batch mixing needs.

Small horizontal ribbon mixers: Utilizing a horizontal U-shaped barrel with dual inner and outer ribbons, the outer ribbon pushes the material to the center, while the inner ribbon conveys it in the opposite direction, creating a strong convection circulation. They achieve high mixing uniformity, complete batch mixing in 3-5 minutes, and have low residual volume. Capacities range from 50L to 500L.

Vertical mixers: Utilizing a vertical barrel with a bottom spiral, the spiral lifts the material to the top, where it then falls back by gravity. They occupy only 1-2 square meters, have power ratings of 1.5-7.5kW, and have capacities of 5L to 100L.

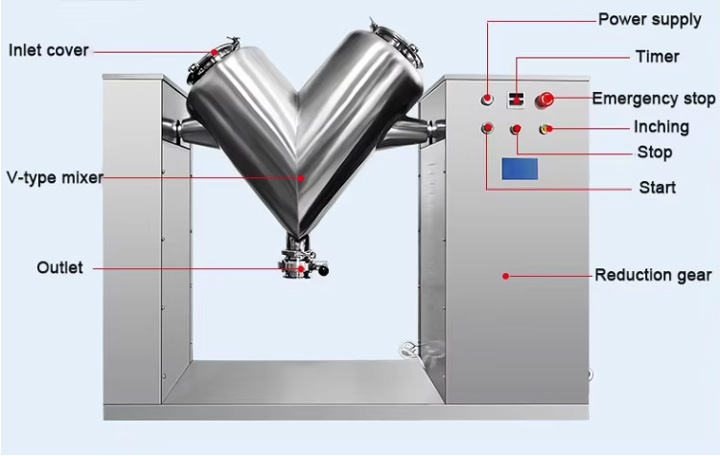

V-type mixers: Composed of an asymmetric double-conical barrel, the barrel's rotation causes the material to flip and shift, achieving mixing through diffusion. The mixing process is gentle and shear-free, protecting fragile additives. Capacities range from 5L to 200L.

The main function of the Feed Additive for Small mixer machine is to achieve uniform blending of trace additives with base powder, addressing the need for precise mixing in small-volume applications.

Uniform mixing of additives: It can evenly distribute additives in the feed to ensure that each animal can take in enough additives.

Improve feed utilization: By uniform mixing, the digestibility of feed can be improved and waste can be reduced.

Improve animal production performance: It can effectively increase the growth rate of animals, enhance immunity, improve meat quality, etc.

Reducing breeding costs: By improving feed utilization and production performance, breeding costs can be effectively reduced.

The Feed additive for small mixer machine consists of a mixing barrel, transmission, stirring components, and feed/discharge ports. The barrel is mostly made of stainless steel to ensure cleanliness and pollution-free. The stirring components are driven by the transmission to achieve uniform mixing of the additives.

Mixing cylinder: It is welded into a V shape by two asymmetric cylinders to promote three-dimensional tumbling of materials.

Frame and support: Heavy steel structure frame to ensure operation stability, adjustable feet to adapt to different sites.

Drive motor: variable frequency speed motor (0.75-5.5kW), speed range 10-25rpm, optional explosion-proof motor.

Liquid spraying device: evenly add liquid additives (such as vitamin E oil)

Feed inlet: top design, with sealing cover (dustproof), optional vacuum feeding interface.

Discharge valve: pneumatic/manual butterfly valve, fast discharge speed, special design of no dead angle discharge port, residual <0.3%.

Optional additional configuration: Jacket heating/cooling, processing of heat-sensitive materials (such as probiotics).

The working principle of feed additive for small mixer machine mainly relies on the rotating blades or drums inside the machine to fully mix additives and feed through mechanical stirring.

Horizontal mixer: It consists of a horizontally placed cylinder with a mixing blade installed inside. The materials are mixed by the rotation of the blade.

Vertical mixer: It consists of a vertically placed cylinder with a mixing blade installed inside. The materials are lifted up by the rotation of the blade and then fall from the top to achieve mixing.

Drum mixer: It consists of an inclined drum. The materials roll in the drum and are mixed by friction.

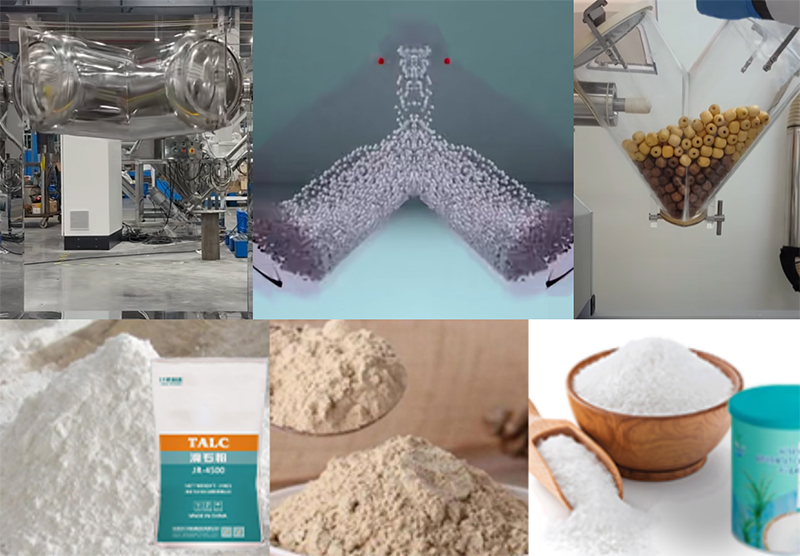

The Feed Additive for Small Mixer Machine is compatible with a wide variety of feed-related materials. Whether it's a laboratory formulation or a homemade premix for a small farm, it can meet multi-material mixing needs and is suitable for preparing feed for different livestock species.

Vitamin additives: including vitamins A, D, E, K and B vitamins, etc., can meet the vitamin needs of animals at different growth stages and improve the immunity and production performance of animals.

Mineral additives: such as macro-element additives such as calcium, phosphorus, sodium, chlorine, potassium, and trace element additives such as iron, zinc, manganese, copper, iodine, selenium, etc., which help maintain animal bone health and promote metabolism.

Amino acid additives: Common ones include lysine, methionine, threonine, etc., which are used to balance the amino acid composition in feed, improve protein utilization, and promote animal growth.

Growth promoters: such as antibiotic growth promoters (within the permitted range), enzyme preparations, probiotics, etc., can promote animal growth and improve feed conversion rate.

Antioxidants: such as ethoxyquin, butylated hydroxyanisole (BHA), etc., can prevent the oxidation and deterioration of fats, vitamins and other ingredients in feed, and extend the shelf life of feed.

Antifungal agents: such as propionic acid, sorbic acid and its salts, can inhibit the growth of mold in feed, prevent feed from mildew, and ensure animal health.

Flavoring agents: including sweeteners, flavoring agents, etc., can improve the palatability of feed and increase the feed intake of animals.

| Type |

Swept Volume (L) |

Total Volume (L) |

Mixing Power (kw) |

LHY-10 |

| VH-2 | 0.8 | 2 | 0.04 | |

| VH-5 | 2 | 5 | 0.55 | |

| VH-8 | 3.2 | 8 | 0.55 | |

| VH-10 | 4 | 10 | 0.55 |

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

| Model | Total volume(L) | Capacity(kg) | Mixing time(Minutes) | Power(kw) | Total height(m) | Weight(kg) | |

| CF-DSH-1 | 1000 | 400-600 | 5-10 | 4 | 2775 | 1200 | |

| CF-DSH-2 | 2000 | 800-1200 | 5-10 | 5.5 | 3424 | 1500 | |

| CF-DSH-6 | 6000 | 2400-3600 | 5-10 | 15 | 4960 | 3500 | |

| CF-DSH-8 | 8000 | 3200-4800 | 5-10 | 18.5 | 5378 | 4000 | |

| CF-DSH-10 | 10000 | 4000-6000 | 5-10 | 18.5 | 5678 | 4300 | |

| CF-DSH-12 | 12000 | 4800-7200 | 5-10 | 22 | 6015 | 4500 | |

| CF-DSH-15 | 15000 | 6000-9000 | 5-10 | 30 | 6650 | 5000 | |

| CF-DSH-20 | 20000 | 8000-12000 | 5-10 | 37 | 7176 | 6000 |

Compared with large mixers, the advantages of the Feed Additive for Small Mixer Machine lie in its adaptability to small capacities and flexible operation. This makes it more user-friendly for users with limited budgets or small production demands. At the same time, it can still guarantee a mixing uniformity of over 90%, meeting the core requirements of additive mixing.

Small size and small footprint: Suitable for limited space in small farms or family farming.

Easy to operate and easy to use: No professional technicians are required to operate, saving labor costs.

High mixing efficiency and good uniformity: It can quickly mix additives with feed evenly to ensure the effective use of additives.

Low price and high cost performance: Compared with large mixers, small mixers are more affordable and more suitable for the economic conditions of small farms.

The mixing amount of small feed additive mixers varies depending on the equipment model and type. Common small vertical feed additive mixers usually mix about 50-300 kg at a time, such as a 100 kg small household multifunctional feed mixer, which has a capacity of 314 kg. The mixing amount of small horizontal feed additive mixers is also roughly within this range. There are different models with a discharge of 200-2000L, and the corresponding mixing amount is about 200-2000 kg.

When choosing a feed additive for small mixer machine, you need to carefully consider your needs. First, clarify the application and production capacity, then choose a vertical or horizontal model based on your needs. Stainless steel is preferred to avoid corrosion and contamination from additives. Regarding performance, focus on mixing uniformity and residual rate.

When purchasing feed additive for small mixer machine, you need to consider the following factors according to your actual situation:

Farming scale: Choose a mixer with appropriate capacity according to the farming scale.

Feed type: Choose a mixer suitable for mixing various feed types.

Budget: Choose a mixer with high cost performance according to the budget.

After-sales service: Choose a brand with good after-sales service.

The price of small feed additive mixer varies depending on the equipment model, material and functional configuration. The basic model is made of carbon steel, which is suitable for conventional additive mixing; the mid-range model is upgraded to 304 stainless steel to meet higher hygiene requirements; the high-end model is equipped with 316L stainless steel, PLC intelligent control system and CIP cleaning function, which is suitable for GMP standard production. Special requirements (such as explosion-proof design, heating/cooling jacket) can be customized, and the price will be adjusted accordingly. We provide a variety of options, from laboratory small machines to commercial production equipment, covering different production capacity requirements. We need to flexibly select and match according to the actual production scale and budget to ensure the best cost performance.

When using a small mixer to process feed additives, it's important to standardize the feeding sequence and mixing parameters, ensure personal and equipment safety precautions, prioritize cleaning and maintenance, and prevent corrosion. Adjust the operation for specific additives.

Material pretreatment: Ensure the particle size of the additive and base powder are similar. Agglomerated materials should be crushed in advance to prevent uneven mixing.

Material compatibility: When working with highly acidic and alkaline additives, use a 316 stainless steel model to prevent corrosion and contamination.

Operational specifications: Feed the feed in the order of "small ingredients first, then large ingredients." Keep the mixing time within 5-15 minutes to avoid over-mixing and stratification.

Cleaning and maintenance: Clean the drum wall promptly after each use and regularly inspect mixing components for wear to ensure the purity of the next batch and the stability of the equipment.

The Feed Additive for Small Mixer Machine is a core device for laboratory R&D, small-scale farms, and small-batch additive production. With a small capacity of 5L-100L and a variety of options, including vertical, horizontal, and V-shaped models, it can flexibly adapt to different scenarios. Its 304/316 stainless steel material ensures additive purity, and its customizable design accommodates specialized material mixing, providing reliable support for nutritional stability and safety in small-batch feed production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.