It has multiple functions such as crushing, mixing, dispersing, and drying, and can meet the material handling needs of different industries.

![]()

![]()

Price:$200.00-$1,000.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 100-3000 (kg)

Mixing time: 5-20min

Mixing speed: 115-60r/min

Power: driven by reduction motor

Material: Stainless steel、Carbon Steel

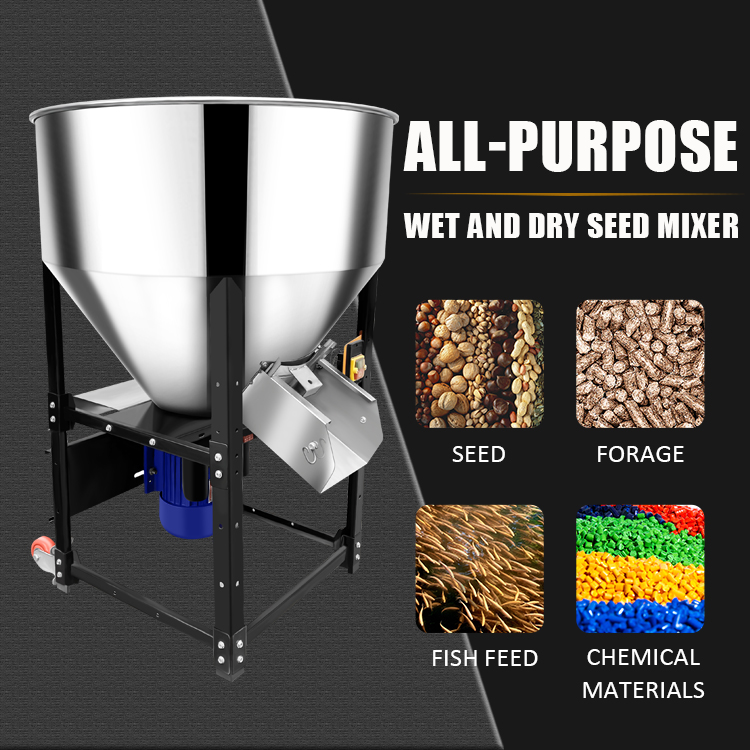

Mixed materials: Used to mix feed, grains, beans, feed additives, chemical raw materials, pigments, coatings, pharmaceutical raw materials, tablet preparations, food raw materials, condiments, cement, lime and other powder, granular and liquid materials.

Commitment: 1Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Vertical crushing and mixed machine is an advanced equipment with the ability to efficiently crush and mix feed ingredients. Through high-speed rotating blades and dual-shaft mixers, it can quickly and evenly crush and mix various feed ingredients to ensure the uniformity and quality of the feed. The vertical crushing and mixed machine not only improves the efficiency of feed production, but also meets the needs of breeding enterprises for high-standard feed, bringing significant benefits to the animal husbandry and feed processing industries.

The Vertical crushing and mixed machine is versatile and suitable for crushing and mixing of various feed ingredients. It can handle various powdery, granular and lumpy feed materials, including grains, beans, feed additives, etc. The design of the vertical crushing and mixed machine enables it to quickly and thoroughly crush the raw materials while achieving a uniform mixing effect through the rotational motion of the twin-shaft agitator. This versatility makes the vertical crushing and mixed machine an indispensable and important equipment in the feed production line, able to meet the feed production processes of different sizes and needs.

Commonly used materials for vertical crushing and mixed machines include carbon steel and stainless steel. These two materials have different characteristics and scope of application:

Carbon Steel: Carbon steel is a common metal material with high strength and durability. Vertical crushing and mixing machines made of carbon steel are suitable for general industrial applications and can handle a variety of materials. Its advantages include relatively low cost, ease of processing and maintenance. However, carbon steel may not be resistant enough to certain corrosive materials, so other materials may be needed when handling some special chemicals or food products.

Stainless Steel: Stainless steel is a corrosion-resistant metal material commonly used in industries that require high hygiene standards, such as food, pharmaceuticals, and cosmetics. Stainless steel vertical crushing and mixing machine has good corrosion resistance and can resist acid, alkali, moisture and other corrosive factors. Additionally, stainless steel is easy to clean and maintain, helping to prevent cross-contamination. Stainless steel can be selected from different grades of stainless steel materials according to specific application requirements, such as 304, 316, etc.

Vertical crushing and mixed machine is a multifunctional equipment widely used in many industries. The application industries of vertical crushing and mixing machine and their specific application materials in various industries will be introduced in detail below.

Feed processing industry: Feed processing plants usually need to produce various types of feed in large quantities, including pellet feed, powdered feed, and block feed. Vertical crushing and mixing machine can process different forms of feed ingredients and crush and mix them into uniform feed.

Chemical Industry: It can be used to mix chemical raw materials, such as pigments, dyes, coatings, glue, etc. In addition, it can also be used to mix different types of chemical materials to achieve specific chemical reactions. Vertical crushing and mixing machines are widely used in the chemical industry, including pigment manufacturing, coating production, resin processing, etc.

Pharmaceutical Industry: Vertical crushing and mixing machine can also be used to mix different types of pharmaceutical raw materials to achieve drug compounding and compatibility. In the pharmaceutical industry, vertical crushing and mixing machines are often used in granule preparation, tablet preparation, drug coating and other processes in the pharmaceutical process.

Food Industry: Vertical crushing and mixing machine can also be used to mix different types of food raw materials to achieve specific food processing needs. In the food industry, vertical crushing and mixing machines are often used in flour manufacturing, candy production, condiment ingredients and other processes.

Building materials industry: Vertical crushing and mixing machine can be used to mix building material raw materials, such as cement, lime, stone powder, etc., to prepare building materials. Vertical crushing and mixing machine can also be used to mix different types of building material raw materials to achieve specific building material preparation needs.

Metallurgical industry: Vertical crushing and mixing machine can be used to mix metallurgical raw materials, such as metal powder, ore, etc., to prepare metallurgical materials. Vertical crushing and mixing machine can also be used to mix different types of metallurgical raw materials to achieve specific metallurgical process requirements.

Vertical crusher mixer is a multi-functional equipment mainly used for crushing and mixing various feed raw materials. Here's how it works:

Crushing stage: The feed raw materials first enter the crushing chamber of the vertical crushing mixer through the feed port. In the crushing chamber, high-speed rotating blades or hammers are installed, which crush and pulverize the feed materials. The broken feed particles will pass through the screen and the required particle size will pass, while the larger particles will continue to be broken by the blade or hammer until the required particle size is met.

Mixing stage: The crushed feed particles enter the mixing chamber, which is equipped with a double-shaft mixer. The twin-shaft mixer uses high-speed rotation and staggered mixing blades to evenly mix feed ingredients. The design of the mixer can ensure that the feed ingredients are fully mixed, so that the various ingredients are evenly distributed, improving the quality and nutritional balance of the feed.

Discharging stage: The mixed feed is discharged through the discharging port. The discharging speed and amount can be controlled by adjusting the switch of the discharging port.

Compact structure

The overall structure design is compact and the floor space is relatively small.

Good crushing effect

Using high-speed rotating blades or hammers for crushing, the feed raw materials can be quickly broken into smaller particles.

Uniform mixing effect

Equipped with a mixer, the crushed feed ingredients are evenly mixed through the stirring device.

Easy to operate

It usually has a user-friendly control panel and operating interface, and the operator can control the operation of the equipment with only simple operations.

High production efficiency

The crushing and mixing processes of the vertical crushing mixer can be carried out at the same time, saving production time.

Strong adaptability

It can flexibly adjust the process parameters of crushing and mixing to meet the requirements of different feed formulas.

| Model | Speed | Power | Dimension | Diameter x Height |

| 50 KG | 40 RPM | 0.75 KW | 800*780*980 | 780*420 |

| 75KG | 40 RPM | 1.5KW | 950*900*980 | 900*420 |

| 100 KG | 40 RPM | 1.5 KW | 1050*1000*980 | 1000*420 |

| 150 KG | 40 RPM | 2.2 KW | 1150*1100*980 | 1100*420 |

| 200 KG | 40 RPM | 3 KW | 1250*1200*1080 | 1200*490 |

| 250 KG | 40 RPM | 4 KW | 1350*1300*1100 | 1300*490 |

| 400 KG | 40 RPM | 5.5 KW | 1450*1400*1300 | 1400*560 |

| 500 KG | 40 RPM | 7.5 KW | 1550*1500*1400 | 1500*560 |

There are some differences in structure and working methods between vertical crushing and mixed machine and horizontal crushing and mixed machine.

| Vertical crushing and mixing machine | Horizontal crushing and mixing machine |

|

|

| Structure: The main axis is perpendicular to the ground, and the overall layout is vertical. | Structure: The main shaft is placed horizontally, and the overall layout is horizontal. |

| Covered area: Usually has a small footprint and is suitable for places with limited space. | Covered area: Usually the floor space is larger, suitable for places with wider space. |

| Material handling capacity: usually suitable for small batch material handling, suitable for laboratories or small-scale production. | Material handling capacity: usually has large material handling capacity and is suitable for large-scale production. |

| Usage scenarios: Suitable for smaller-scale feed processing plants or laboratories, with compact structure and small footprint. | Usage scenarios:Suitable for medium and large-scale feed processing plants with large production capacity. |

Xinxiang Dahan vertical crushing and mixed machine manufacturer is a company specializing in manufacturing vibration equipment and one of the vertical crushing and mixed machine manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The vertical crushing and mixing machine adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan vertical crushing and mixed machine manufacturer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. It is one of the trustworthy vertical crushing and mixed machine manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.