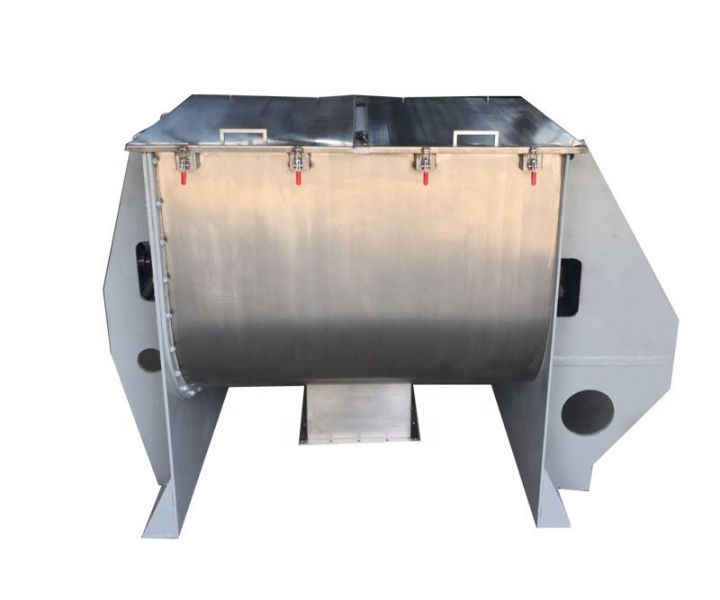

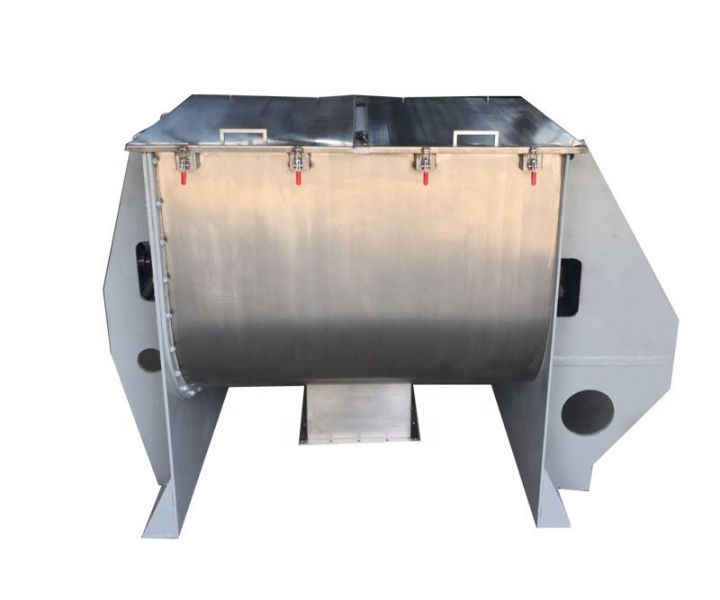

It is suitable for mixing ceramic tile bond raw materials and achieves rapid and even mixing through spiral belt rotation.

![]()

![]()

Price::$899.00-$7,500.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Power: 3-75kw

Frequency: 50HZ、60HZ

Mixing speed: 15-60r/min

Voltage: 380 Volt、Special customized 400v、 480v (Can be specially customized according to customer requirements)

One-time mixing: 100-6000 (kg) (If it exceeds 6000kg, it can be customized according to needs)

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Used in the construction industry to mix raw materials for ceramic tile bond, such as cement, lime, silica sand, polymer powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Tile bond ribbon mixer is a piece of equipment specially designed for mixing tile bond raw materials. It usually consists of a host machine, a transmission device, a spiral belt, a mixing barrel and other parts. First, raw materials such as cement, lime, silica sand, polymer powder, etc. are added to the mixing barrel. Secondly, through the rotation and pushing of the spiral belt, the raw materials are fully mixed in the mixing barrel to achieve uniform dispersion.

The design of the ribbon ensures that the raw materials will not agglomerate or stratify during the mixing process, ensuring the mixing quality. The operation of this mixer is simple and efficient. It can quickly and evenly mix various adhesive raw materials, improve production efficiency and ensure that the mixed tile bond has stable performance. It is suitable for the ceramic tile production and installation process in the construction industry.

Tile bond ribbon mixer plays an important role in the construction industry. It is widely used in ceramic tile production and installation processes for mixing raw materials for tile bonds.

Mixing raw materials: cement, lime, silica sand, polymer powder, etc., processed by a ribbon mixer, ensure that the tile bond has a uniform texture and excellent bonding performance.

In ceramic tile production: the mixer can mix raw materials quickly and efficiently, improve production efficiency, and ensure stable quality of the tile bond produced.

During the tile installation process: Using a high-quality tile bond ensures a strong bond between the tile and the substrate, extending service life and improving aesthetics.

The working principle of tile bond ribbon mixer is as follows:

Feeding stage: First, put cement, lime, silica sand, polymer powder and other tile bond raw materials into the mixing barrel.

Ribbon mixing: When the mixer is started, the ribbon begins to rotate, pushing the raw materials to the other end of the mixing barrel. The design of the spiral belt allows the raw materials to be continuously turned and moved in the mixing barrel, thereby achieving uniform mixing of the raw materials.

Mixing uniformity control: By controlling the rotation speed and mixing time of the ribbon, the mixing uniformity of the raw materials can be controlled to ensure that each ingredient is fully mixed and avoid agglomeration or stratification.

Mixing completed: When the raw materials are mixed evenly, stop the operation of the mixer and take out the mixed tile bond raw materials for subsequent ceramic tile production processes.

Uniform mixing

The ribbon mixer can evenly mix the tile bond raw materials to avoid agglomeration or stratification of the raw materials and ensure stable mixing quality.

Efficient and fast

The mixer is simple to operate and can quickly mix the raw materials, improving production efficiency and saving time and costs.

Excellent bonding properties

The tile bond mixed by the ribbon mixer has excellent bonding properties, ensuring a strong bond between the tiles and the substrate.

Convenient operation

The operation control is simple, the mixing time and speed can be adjusted as needed, and the flexibility is high, suitable for different production needs.

Strong stability

The equipment has a solid structure, smooth and reliable operation, can work for a long time without being prone to failure, and ensures production continuity.

Wide application

Tile bond ribbon mixer is widely used in the construction industry and is suitable for mixing various tile bond raw materials.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The perfect combination of tile bond and ribbon mixer lies in the rotation and pushing of the ribbon, which allows the bond raw materials to be fully mixed in the mixing barrel, ensuring that the ingredients are evenly dispersed and avoiding agglomeration or delamination. This mixing method ensures stable quality and excellent bonding performance of the tile adhesive, providing reliable support for tile production and installation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.