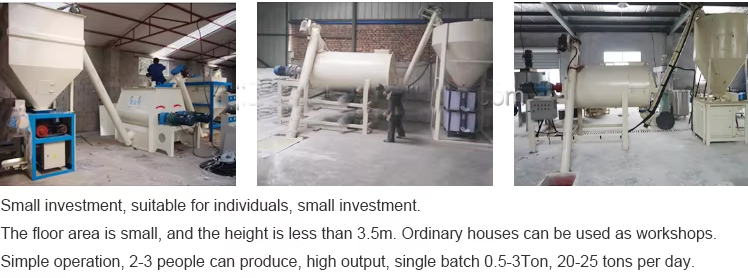

Efficient and sturdy equipment that can quickly mix high-temperature resistant materials and improve production efficiency.

![]()

![]()

Price:$1,000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing: 100-6000kg

Mixing speed: 15-60r/min

Power: 3-75kw

Weight: 500kg-7500kg

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: It is widely used in metallurgy, construction, chemical industry, electric power and other fields to manufacture refractory bricks, refractory castables, refractory coatings and other products.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Refractory mixer is a specialized machine used in industries like construction, ceramics, and metallurgy for mixing refractory materials. These mixers are designed to handle the high temperatures and abrasiveness of refractory materials, which are used in applications that require resistance to heat, corrosion, and abrasion. Mixing capacities range from 5kg to 5000kg, and batch mixing times range from 3 minutes to 10 minutes.

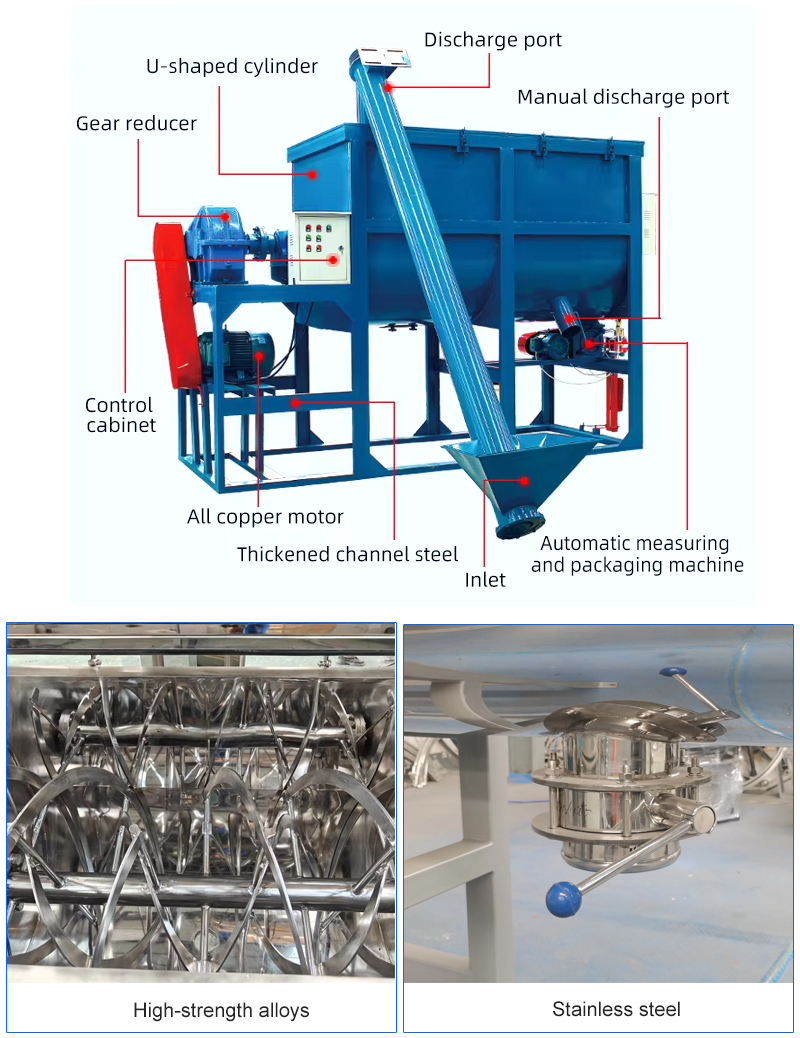

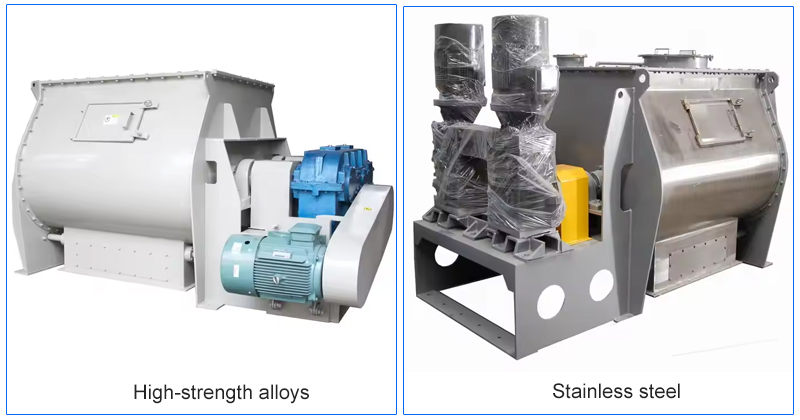

Refractory mixers withstand the harsh conditions of mixing heavy and abrasive materials. They are typically made of durable materials, such as stainless steel or other high-strength alloys, and feature a variety of mixing mechanisms, such as paddles, blades, or augers, to effectively mix refractory materials. These mechanisms ensure proper distribution of additives and binders in the mix, and refractory mixers typically come with adjustable speed settings and mixing options to suit different types of refractory materials and mixing requirements.

Refractory mixers are used in various stages of refractory material production, including:

Raw Material Blending: Mixing different types of raw materials, such as clay, silica, and alumina, to achieve the desired properties.

Additive Blending: Incorporating additives like binders, plasticizers, and water into the refractory mix.

Batch Mixing: Mixing smaller quantities of refractory materials for specific applications or testing purposes.

Continuous Mixing: Mixing a continuous flow of materials for large-scale production.

Refractory paddle Mixer

Mixing amount each time: 300-3000kg

The agitator of the refractory paddle mixer is in the shape of a paddle. The paddle rotates to generate shearing force and pushing force to mix the refractory powder, which is suitable for mixing various powders. It is widely used in the refractory material preparation process to improve production efficiency and product quality.

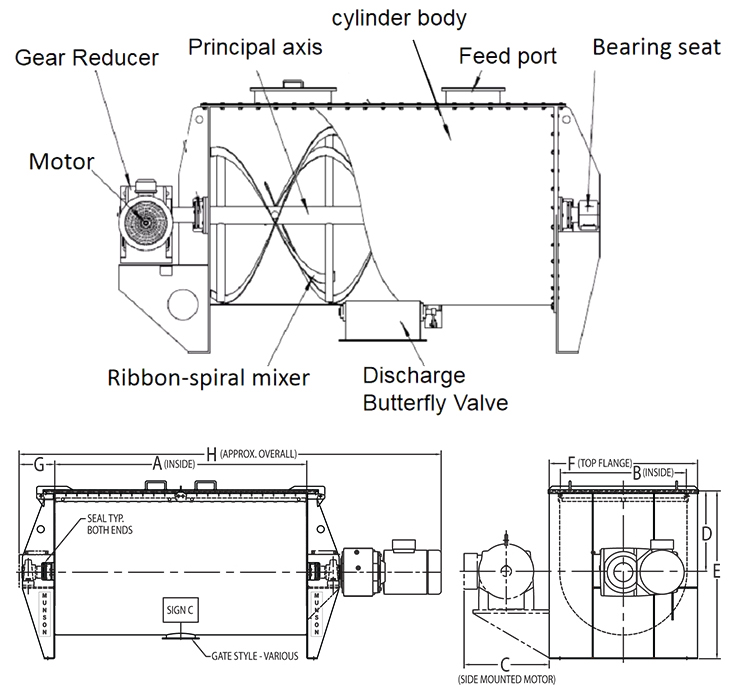

Refractory ribbon mixer

Mixing amount each time: 100-6000kg

The agitator of the refractory ribbon mixer adopts the shape of ribbon. The spiral belt mixes refractory material powder by rotating and pushing, and is suitable for some occasions that require high mixing effects. It is often used to prepare high-viscosity refractory materials, such as castables, mortars, etc.

Refractory intensive mixer

Mixing amount each time:Mixing amount each time: 100-1000 kg

The mixer of the refractory intensive mixer adopts a powerful stirring device. The powerful mixing device uses high-speed rotation and strong shearing force, and is suitable for occasions that require high mixing effects. It is usually used to prepare high-demand refractory materials, such as high-temperature cementitious materials, etc.

Refractory pan mixer

Mixing amount each time: 100-1000 kg

The raw materials are mixed through the disc structure and rotating motion. The high-speed rotating stirrer in the disc is used to continuously rub, collide and mix the raw materials on the disc surface, thereby achieving uniform mixing of the raw materials. Suitable for mixing various refractory materials, such as refractory bricks, refractory castables, etc.

Improve mixing efficiency

The refractory mixer uses a professional mixing system and agitator to efficiently mix refractory materials. It can quickly and evenly mix refractory materials of different particles, improve mixing efficiency, and save time and labor costs.

Uniform mixing

The refractory mixer can fully mix different types and colors of refractory materials through the stirring and mixing system to ensure that the mixed materials are evenly distributed. This improves product consistency and quality and avoids quality issues caused by uneven mixing.

Precise proportioning

The refractory mixer can perform precise proportioning as needed to ensure that the composition and proportion of refractory materials are accurate. This is important for specific fire resistance performance requirements to provide a mix of materials that meets technical specifications and product standards.

Improve production efficiency

The efficient mixing and precise proportioning of the refractory mixer can improve production efficiency. It can quickly complete the mixing process, reduce the production cycle, improve production capacity, and meet market demand.

Reduce manual operations

The refractory mixer has a high degree of automation, reducing the need for manual operations. The operator only needs to set the mixing parameters and monitor the mixing process, and the machine can automatically complete the mixing task, reducing the tediousness and work intensity of manual operations.

Improve safety and environmental protection

The refractory mixer adopts a closed structure, which can effectively control the spread of dust and particulate matter and improve the safety of the working environment. In addition, it can also reduce material waste and pollution, improve resource utilization efficiency and environmental protection awareness.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Mixing Blades: These blades are designed to rotate and cut through the ingredients, ensuring thorough mixing and preventing clumping. The blades can be various shapes, such as paddle blades, helical blades, or twin-shaft blades, depending on the specific application and the type of ingredients being mixed.

Drive Mechanism: This system powers the rotation of the mixing blades. It can be electric, hydraulic, or pneumatic, depending on the desired level of control and the specific requirements of the mixing process.

Discharge System: This mechanism allows the mixed refractory material to be discharged from the mixer. It can be a simple gravity chute or a more complex system involving a conveyor belt or screw feeder.

Refractory mixers can be adjusted and optimized according to specific needs and production environments. Some common customization options for refractory mixers include:

1.Material selection:

According to the required wear resistance, high temperature resistance and other characteristics, suitable materials can be selected to manufacture refractory mixers, such as stainless steel, high-strength alloys, etc.

2.Mixing mechanism adjustment

According to different refractory material properties and mixing requirements, the design of the mixing mechanism can be adjusted, such as changing the shape, number and speed of the agitators, etc.

3.Safety features

To ensure the safety of operators, safety features such as emergency stop buttons, protective covers, etc. can be added.

4.Discharge door selection

Usually, the discharge can be installed at the top, side and bottom positions. The bottom position is common and convenient, the side position is suitable for limited space, and the top position is suitable for special needs.

5.Shaft seal selection

Common shaft seal options include mechanical seals, packing seals, gas seals and lubricating oil seals. Mechanical seals have good sealing performance and wear resistance, packing seals are easy to maintain, gas seals are suitable for occasions with high requirements for material contamination, and lubricating oil seals can reduce friction and extend the life of seals.

6.Hopper and liquid spray system settings

The hopper is convenient for feeding, and the liquid spray system is used to add liquid ingredients such as binders or other additives.

Steel Industry: In the steel industry, refractory mixers are used to mix refractory materials for applications such as linings and cladding in the steelmaking process to withstand high temperatures and wear.

Foundry Industry: The foundry industry utilizes refractory mixers to prepare mixtures for lining materials for melting furnaces, crucibles, and molds that withstand high temperatures.

Cement Industry: Refractory mixers play an important role in the cement industry for mixing and preparing refractory mixtures used in high-temperature equipment such as kilns and rotary furnaces.

Glass Industry: In the glass industry, refractory mixers are used to mix refractory materials for lining melting furnaces and containers to withstand the high temperatures required for glass production.

Incineration Plants: Incineration plants use refractory mixers to mix refractory materials for lining combustion chambers and other high-temperature components to ensure efficient and durable operation.

Power Plants: Refractory mixers are used in power plants to prepare mixtures for high-temperature equipment such as boilers and furnaces that require thermal insulation.

Aluminum Industry: In the aluminum industry, refractory mixers are used to mix materials used to line smelting furnaces and other equipment that produces aluminum.

Xinxiang Dahan refractory mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the refractory mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The refractory mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan refractory mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy refractory mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.